Mitsubishi Montero Sport (2004+). Manual - part 257

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-441

Judgement Criteria (change in the angular accel-

eration of the crankshaft is used for misfire

detection.)

• Misfire has occurred more frequently then

allowed during the last 200 revolutions [when the

catalyst temperature is higher than 950

°C

(1742

°F)].

or

• Misfire has occurred in 20 or more of the last

1,000 revolutions (corresponding to 1.5 times the

limit of emission standard).

.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function

− OBD-II Drive Cycle −

Procedure 6

− Other Monitor

.

.

TROUBLESHOOTING HINTS (The most likely

causes for this code to be set are: )

• Ignition system related part(s) failed.

• Poor crankshaft position sensor.

• Low compression pressure.

• Skipping of timing belt teeth.

• EGR system and EGR valve failed.

• Harness damage in injector circuit, or connector

damage.

• Injector failed.

• PCM failed.

DIAGNOSIS

Required Special Tools:

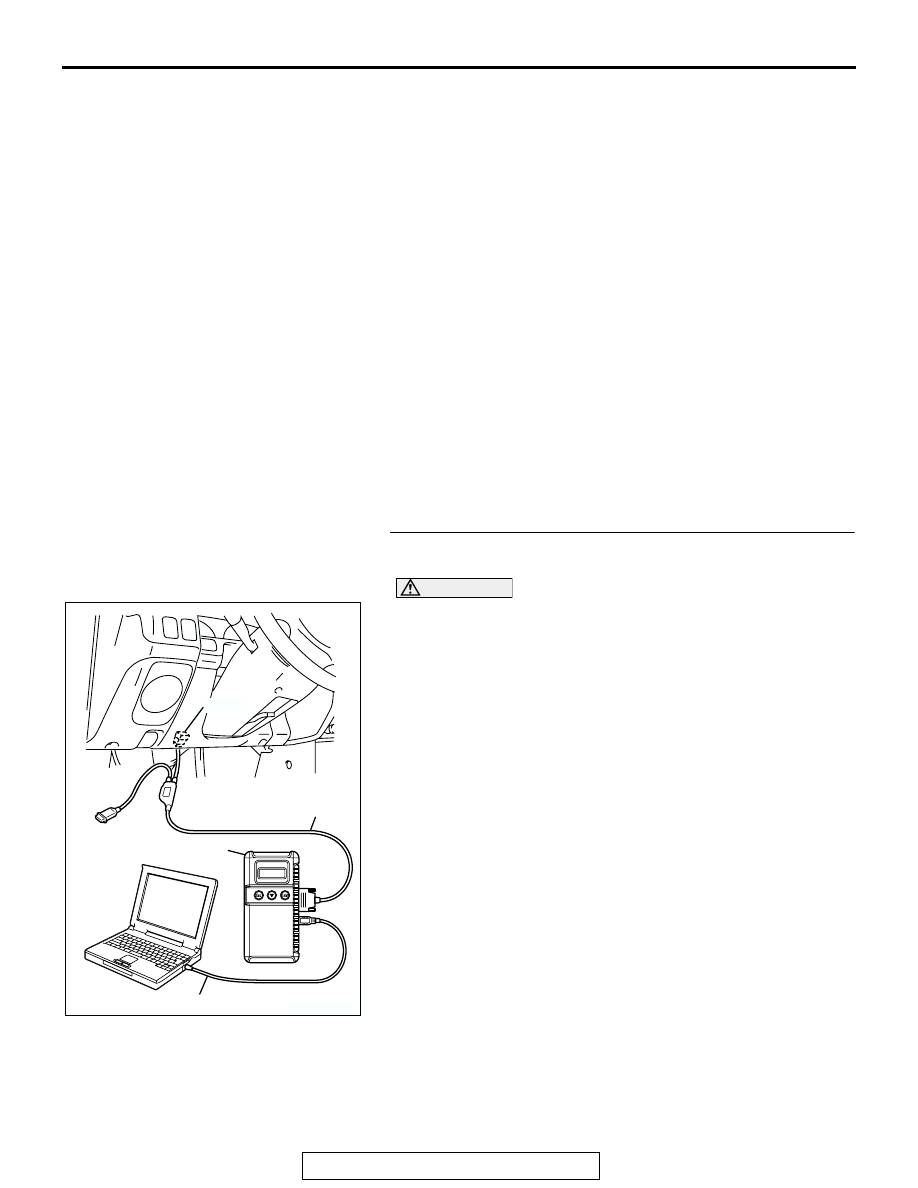

• MB991958: Scan Tool (MUT-III Sub Assembly)

• MB991824: V.C.I

• MB991827: USB Cable

• MB991911: Main Harness B

STEP 1. Using scan tool MB991958, check data list item 22:

Crankshaft Position Sensor.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

(1) Connect scan tool MB991958 to the data link connector.

(2) Start the engine and run at idle.

(3) Set scan tool MB991958 to the data reading mode for item

22, Crankshaft Position Sensor.

(4) Check the waveform of the crankshaft position sensor while

keeping the engine speed constant.

• The pulse width should be constant.

(5) Turn the ignition switch to "LOCK" (OFF) position.

Q: Is the sensor operating properly?

YES : Go to Step 2.

NO : Refer to, DTC P0335

− Crankshaft Position Sensor

Circuit Malfunction

.

AK303629AB

MB991911

MB991827

MB991824

16-PIN