Mitsubishi Montero (2004+). Manual - part 507

TIRE PRESSURE MONITORING SYSTEM (TPMS)

TSB Revision

WHEEL AND TIRE

31-99

CAUTION

• Visually check that TPMS transmitter is not deformed

or damaged.

• When installing the TPMS transmitter, be sure the rim,

grommet and valve nut are clean.

• Ensure that the grommet is located inside the valve

hole before installing the valve nut.

• While installing the valve nut, hold the valve and grom-

met firmly in contact with the rim.

• While installing the valve nut, ensure that the tool is

kept aligned to the valve and the valve hole.

• After installing the valve nut, check that the grommet is

compressed.

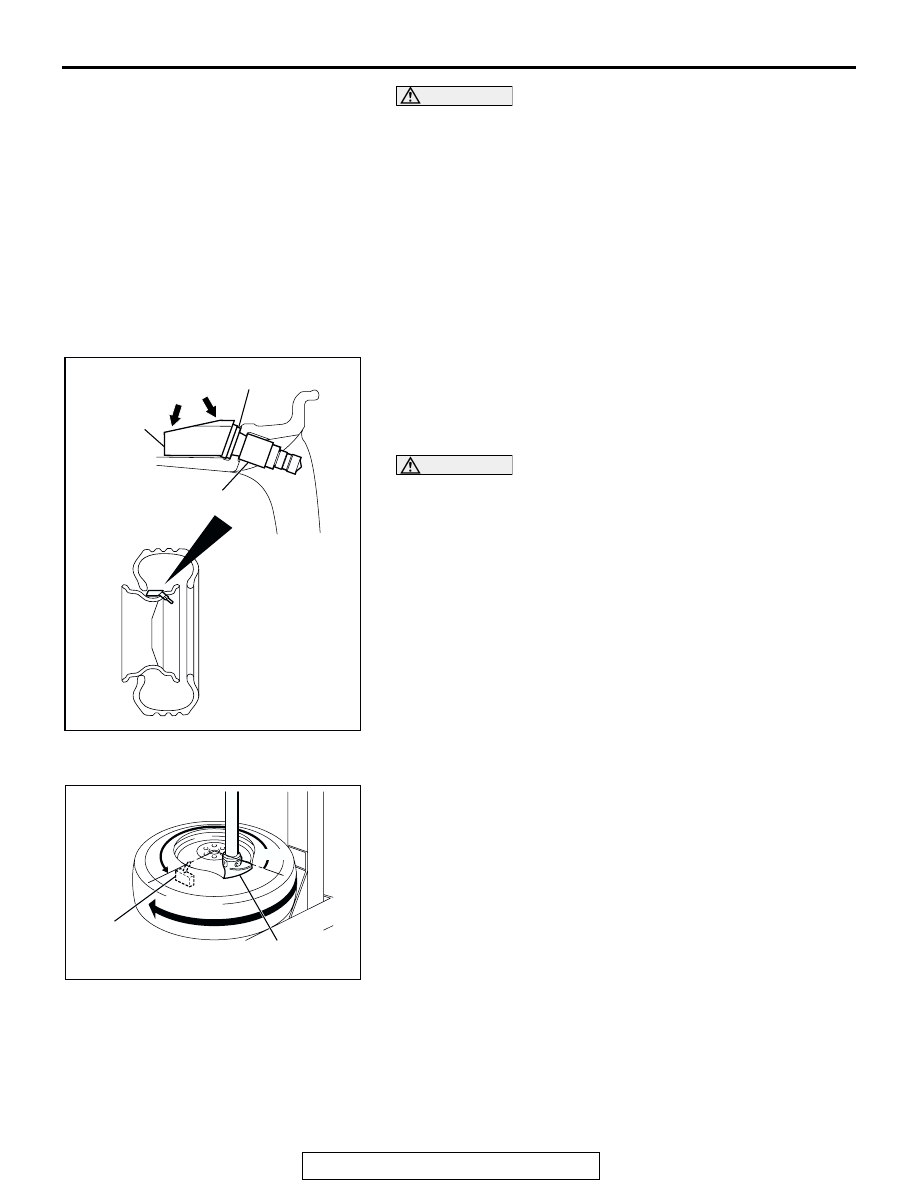

3. Mount TPMS transmitter valve through rim hole as

illustrated. Both holes in the transmitter case should face

away from center of rim. Tighten valve nut finger tight, then

slowly torque the valve nut to 5.5

± 0.5 N⋅m (49 ± 4 inch

pounds).

CAUTION

Install the TPMS transmitter correctly. If the TPMS trans-

mitter is installed incorrectly, it may not work correctly, or

become damaged when the tire is installed.

4. Check that the TPMS transmitter is correctly assembled

(Refer to illustration).

• One side of lower lip of the TPMS transmitter case can

touch the rim after torquing.

• Except for the grommet, valve nut and lower lip of the

TPMS transmitter, no other part of the front of the TPMS

transmitter case should be touching the rim.

.

>>B<< TIRE BEAD MOUNTING

1. Place wheel and tire on turntable of tire mounting machine.

Ensure that the TPMS transmitter is 270 degrees (3 o’clock

position) from mounting head when the outer tire bead is

mounted as illustrated.

2. Lubricate tire well and mount outer tire bead as normal.

Ensure that the tire does not rotate during mounting.

.

AC205463

AC205766

AC206993AB

TPMS

TRANSMITTER

GROMMET

VALVE NUT

HOLES

AC307581AB

TPMS

TRANSMITTER

MOUNTING HEAD

270˚