Mitsubishi Montero (2004+). Manual - part 11

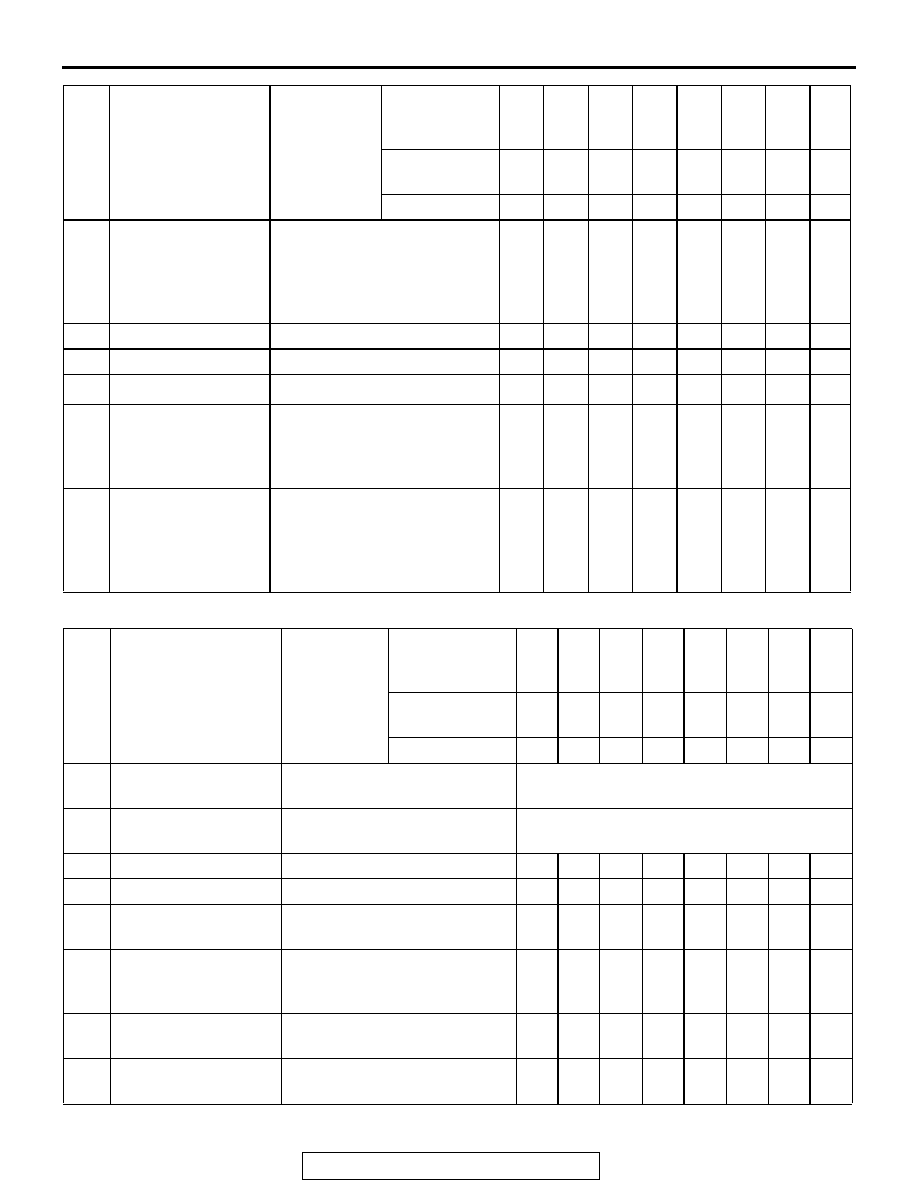

SCHEDULED MAINTENANCE TABLE

TSB Revision

GENERAL <BODY AND CHASSIS>

00-37

.

GENERAL MAINTENANCE SERVICE FOR PROPER VEHICLE PERFORMANCE

4

Evaporative

emission control

system (except

evaporative

emission canister)

Check for leaks and clogging

X

X

5

Spark plugs

Replace

X

6

Ignition cables

Replace

X

X

7

Timing belt

Replace

X

*1

X

*2

X

*4

8

Drive belts (for

generator, water

pump, power

steering pump

Check condition

X

X

X

X

9

Exhaust system

(connection portion

of muffler, muffler

pipes and converter

heat shields)

Check and service

X

*3

X

X

X

NO. EMISSION

CONTROL

SYSTEM

MAINTENANCE

SERVICE

INTERVALS

KILOMETERS

IN

THOUSANDS

24

48

72

96

120 144 168 192

MILEAGE IN

THOUSANDS

15

30

45

60

75

90

105 120

MONTHS

12

24

36

48

60

72

84

96

NO. GENERAL

MAINTENANCE

SERVICE

INTERVALS

KILOMETERS

IN

THOUSANDS

24

48

72

96

120 144 168 192

MILEAGE IN

THOUSANDS

15

30

45

60

75

90

105 120

MONTHS

12

24

36

48

60

72

84

96

10

Engine oil

Change

Every 6 months or every 12,000 km (7,500

miles)

11

Engine oil filter

Replace

Every 6 months or every 12,000 km (7,500

miles)

12

Transmission fluid

Check fluid level and condition X

X

X

X

X

X

X

X

13

Transfer oil

Check oil level and condition

X

X

X

X

14

Engine coolant

Change

X at

first

X

X

15

Coolant hoses

(radiator hose, heater

hose)

Inspect

X

X

X

X

16

Disc brake pads,

rotors

Inspect for wear

X

X

X

X

X

X

X

X

17

Brake hoses

Check for deterioration or

leaks

X

X

X

X

X

X

X

X