Mitsubishi Montero (2002-2004). Manual - part 851

EMISSION CONTROL

TSB Revision

ENGINE AND EMISSION CONTROL

17-67

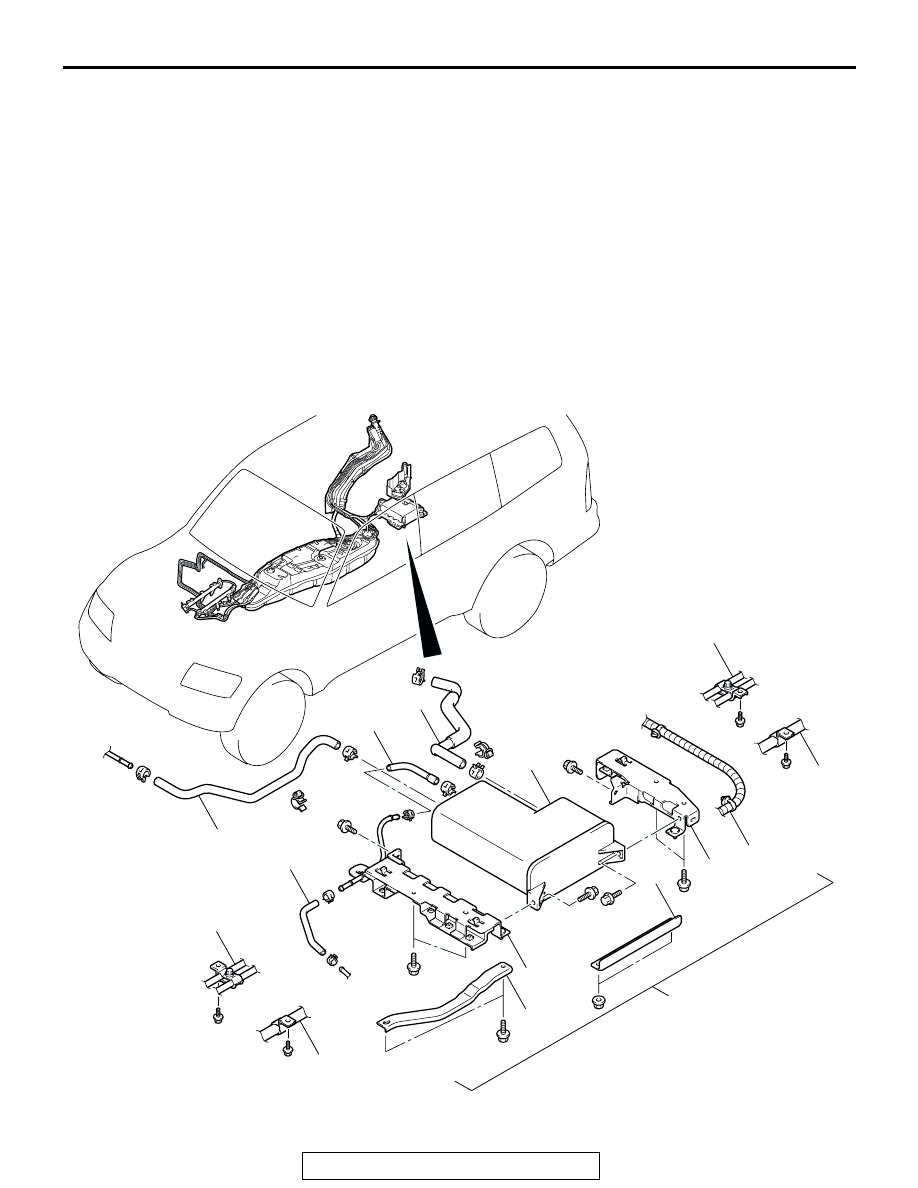

<EVAPORATIVE EMISSION CANISTER>

REMOVAL STEPS

1. ORVR VENT VALVE MODULE

COVER A

2. ORVR VENT VALVE MODULE

COVER B <VEHICLES WITHOUT

REAR HEATER OR REAR A/C>

3. EVAPORATIVE EMISSION

VENTILATION SOLENOID

CONNECTOR

4. VENT HOSE A CONNECTION

5. ORVR VENT VALVE MODULE, CAP,

VENT HOSE, VENT PIPE AND

BRACKET ASSEMBLY

6. EVAPORATIVE EMISSION

VENTILATION SOLENOID

7. CAP

8. VENT HOSE D

9. VENT HOSE B

10. VENT HOSE C

11. VENT PIPE

12. ORVR VENT VALVE MODULE

13. ORVR VENT VALVE MODULE

BRACKET

REMOVAL STEPS (Continued)

AC204037

1

2

9

8

7

6

5

4

3

13

12

11

10

1

2

AB