Mitsubishi Montero (2002-2004). Manual - part 742

TSB Revision

SYMPTOM PROCEDURES

13Ad-17

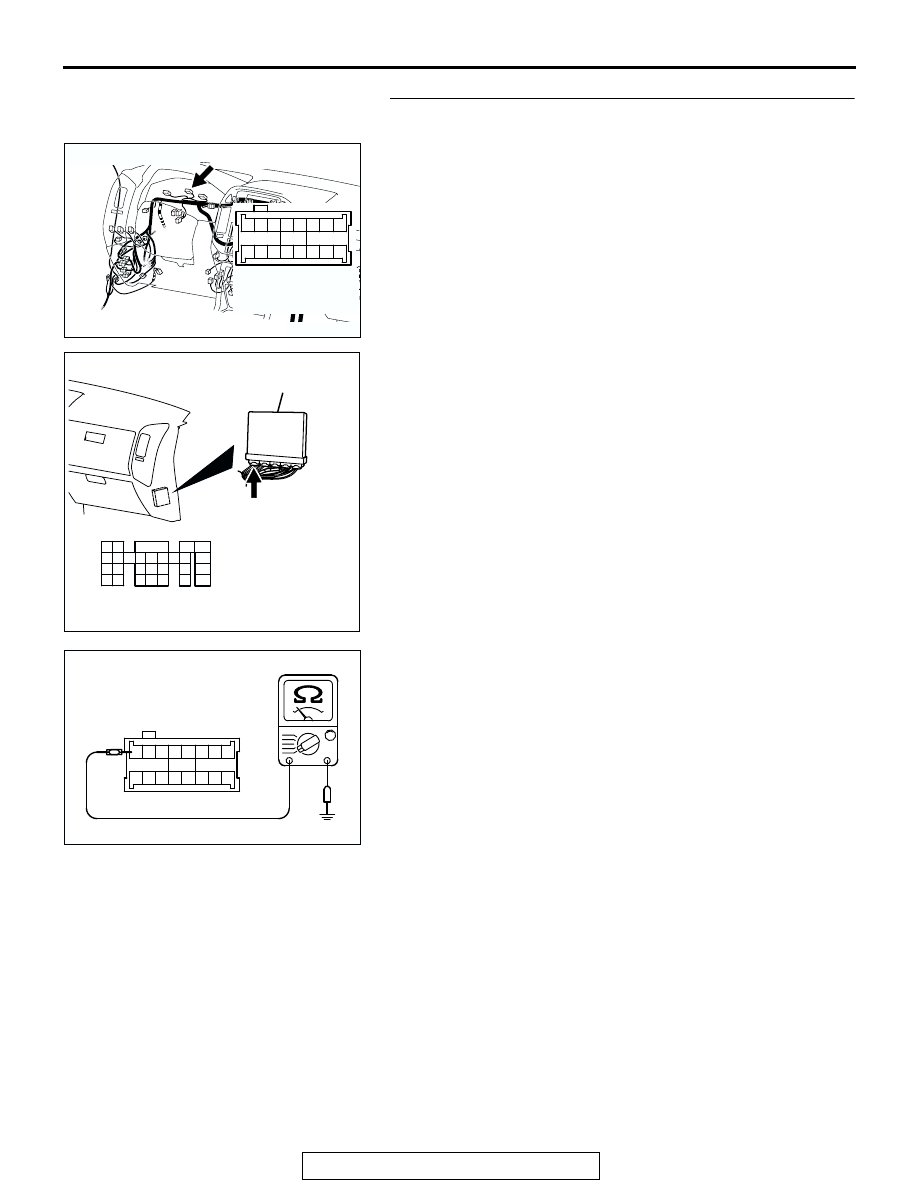

STEP 2. Check the continuity at combination meter

harness side connector D-04.

(1) Disconnect the connector D-04 and measure at the harness

side.

(2) Disconnect the PCM connector D-132.

(3) Check for the continuity between terminal No. 38 and

ground.

• Should be open loop.

Q: Is the continuity normal?

YES : Replace the PCM. Then confirm that the malfunction

symptom is eliminated.

NO : Check harness connector E-111 at the intermediate

connector for damage, and repair or replace as

required. Refer to GROUP 00E, Harness Connector

Inspection

. If intermediate connectors E-111

is in good condition, repair a short circuit to ground

between combination meter connector D-04 (terminal

No. 38) and PCM connector D-132 (terminal No. 7).

Then confirm that the malfunction symptom is

eliminated.

AK200978

37

38

39

40

43

41

42

44

47

45

46

32 31

33

34

35

36

AB

D-04(GR)

HARNESS

CONNECTOR:

COMPONENT SIDE

CONNECTOR: D-04

AK200938

2

3

4

5

6

7

8

9

1

10

14

15

16

17

18

19

20

21

22

23

24

25

26

27

11

12

13

AB

CONNECTOR: D-132

HARNESS CONNECTOR:

COMPONENT SIDE

PCM

D-132(GR)

AK201373

37

38

39

40

43

41

42

44

47

45

46

32 31

33

34

35

36

D-04 HARNESS

CONNECTOR:

COMPONENT SIDE

AK201373AB

37

38

39

40

43

41

42

44

47

45

46

32 31

33

34

35

36