Mitsubishi Montero (2002-2004). Manual - part 559

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13Aa-23

Standard value:

3. If the sensor is defective, replace the heated oxygen sensor.

NOTE: For removal and installation of the heated oxygen sen-

sor, refer to GROUP 15, Exhaust Pipe and Main Muffler

INJECTOR CHECK

M1131005200219

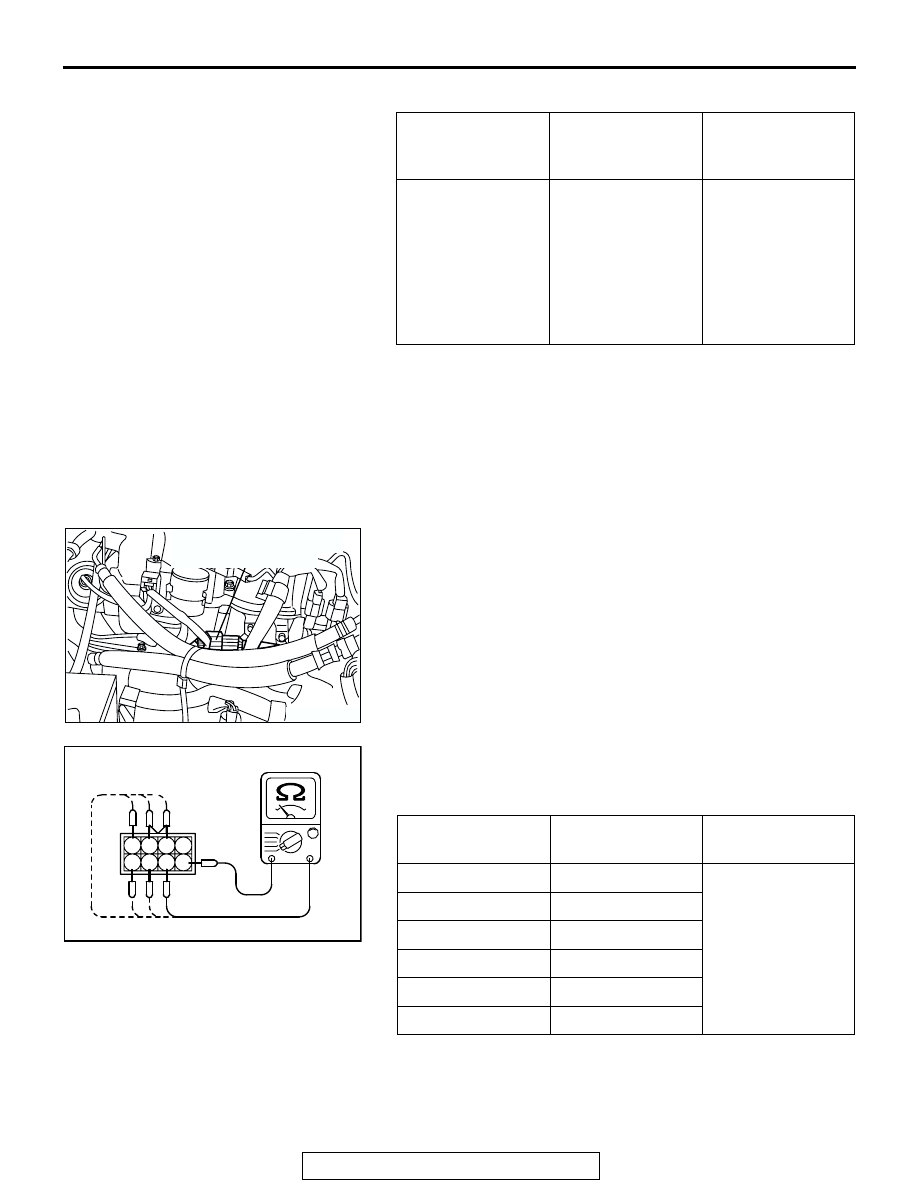

Measurement of Resistance between Terminals

1. Disconnect the injector intermediate connector.

2. Measure the resistor between the injector intermediate male

side connector terminals.

Standard value:

3. Connect the injector intermediate connector.

ENGINE

HEATED OXYGEN

SENSOR OUTPUT

VOLTAGE

REMARKS

When revving

engine

0.6

− 1.0 V

If you make the air/

fuel ratio rich by

revving the engine

repeatedly, a

normal heated

oxygen sensor will

output a voltage of

0.6

− 1.0 V.

AK201314AB

INJECTOR INTERMEDIATE

HARNESS CONECTOR

INJECTOR NO.

MEASUREMENT

TERMINAL

RESISTANCE

NO. 1

8

− 3

13

− 16 kΩ

[20

°C (68°F)]

NO. 2

8

− 2

NO. 3

8

− 1

NO. 4

8

− 7

NO. 5

8

− 6

NO. 6

8

− 5

AKX01494

INJECTOR INTERMEDIATE

MALE SIDE CONNECTOR

1 2 3 4

5 6 7 8

AB