Mitsubishi Montero (2002-2004). Manual - part 557

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13Aa-15

(2) Squeeze the fuel supply line closed to confirm leak-down

occurs from defective fuel pump check valve.

(3) If pressure continues to drop with both fuel lines

squeezed closed, injector(s) are leaking.

14.Release residual pressure from the fuel pipe line. (Refer to

WARNING

Cover the hose connection with shop towels to pre-

vent splash of fuel that could be caused by some

residual pressure in the fuel pipe line.

15.Remove the fuel pressure gauge, and special tools

MD998709, MD998742 and MB991637 from the fuel rail.

16.Replace the O-ring at the end of the fuel high-pressure hose

with a new one.

17.Fit the fuel high-pressure hose into the fuel rail and tighten

the bolts to specified torque.

Tightening torque: 4.9

± 1.0 N⋅m (43 ± 8 in-lb)

18.Check for fuel leaks.

(1) Use scan tool MB991502 to operate the fuel pump.

(2) Check the fuel line for leaks and repair as needed.

19.Disconnect scan tool MB991502.

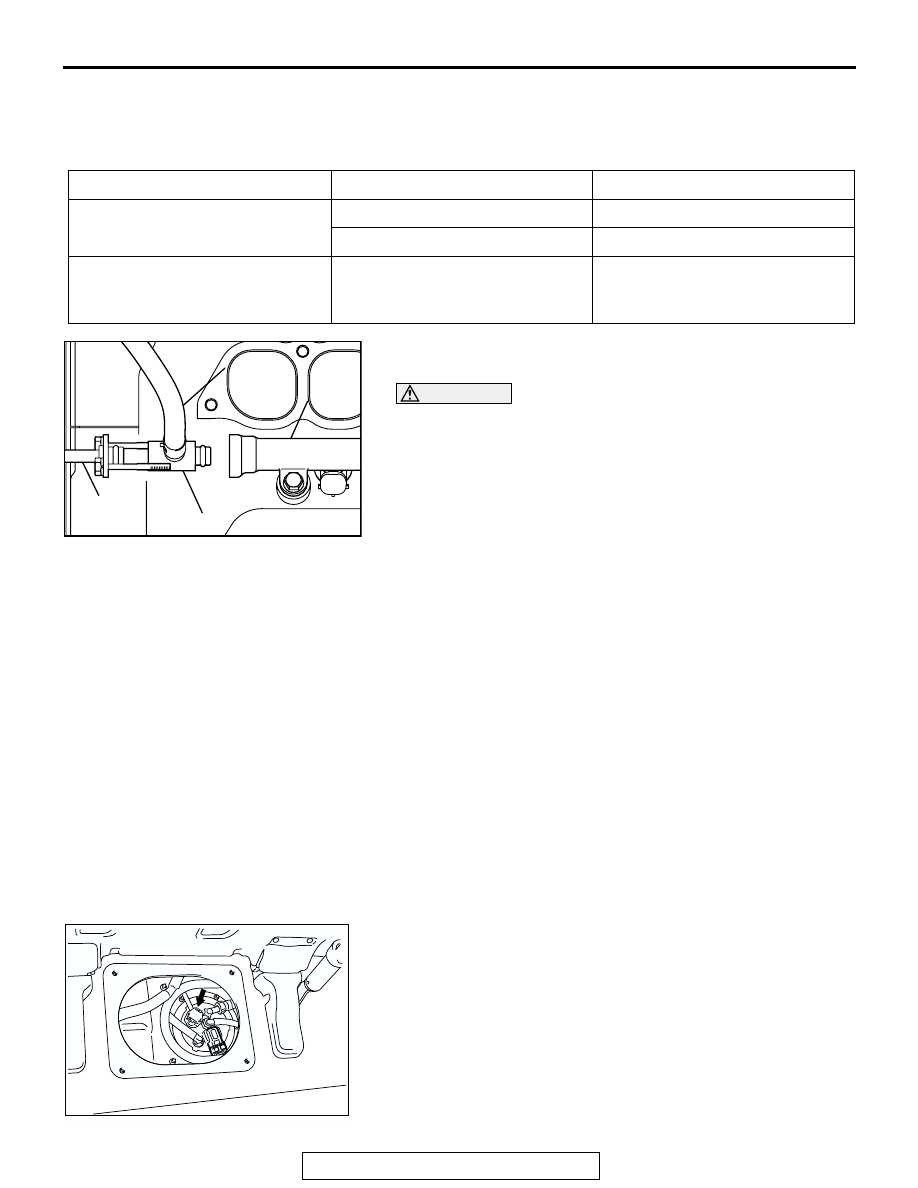

FUEL PUMP CONNECTOR DISCONNECTION

(HOW TO REDUCE PRESSURIZED FUEL LINES)

M1131000900451

When removing the fuel pipe, hose, etc., release fuel pressure

to prevent fuel splay.

1. Turn the ignition switch to the "LOCK" (OFF) position.

2. Fold down the second seat.

3. Remove the service hole cover (upper) and packing.

4. Remove the service hole cover (lower) and packing.

5. Disconnect fuel pump module connector.

6. Start the engine and let it run until it stops naturally. Turn the

ignition switch to the "LOCK" (OFF) position.

7. Connect the fuel pump module connector.

SYMPTOM

PROBABLE CAUSE

REMEDY

Fuel pressure drops gradually

after engine is stopped

Leaky injector

Replace injector

Leaky fuel regulator valve seat

Replace fuel pressure regulator

Fuel pressure drops sharply

immediately after engine is

stopped

Check valve in fuel pump is held

open

Replace fuel pump

AKX01460AB

MD998709

FUEL

RAIL

MD998742

HIGH-

PRESSURE

FUEL HOSE

ACX00218 AM