Mitsubishi Montero (2002-2004). Manual - part 556

ON-VEHICLE SERVICE

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13Aa-11

THROTTLE BODY CLEANING

M1131001000246

1. Start the engine and warm it up until the coolant is heated to

80

°C (176°F) or higher. Stop the engine.

2. Remove the air intake hose from the throttle body.

3. Spray cleaning solvent into the valve through the throttle

body intake port and leave it for approximately five minutes.

4. Start the engine, rev it several times and then idle it for about

one minute. If the idling speed becomes unstable (or if the

engine stalls) due to the bypass passage being plugged,

slightly open the throttle valve to keep the engine running.

5. If the throttle valve deposits are not removed, repeat steps 3

and 4.

6. Unplug the bypass passage inlet.

7. Attach the air intake hose.

8. Use scan tool MB991502 to erase any diagnostic trouble

code.

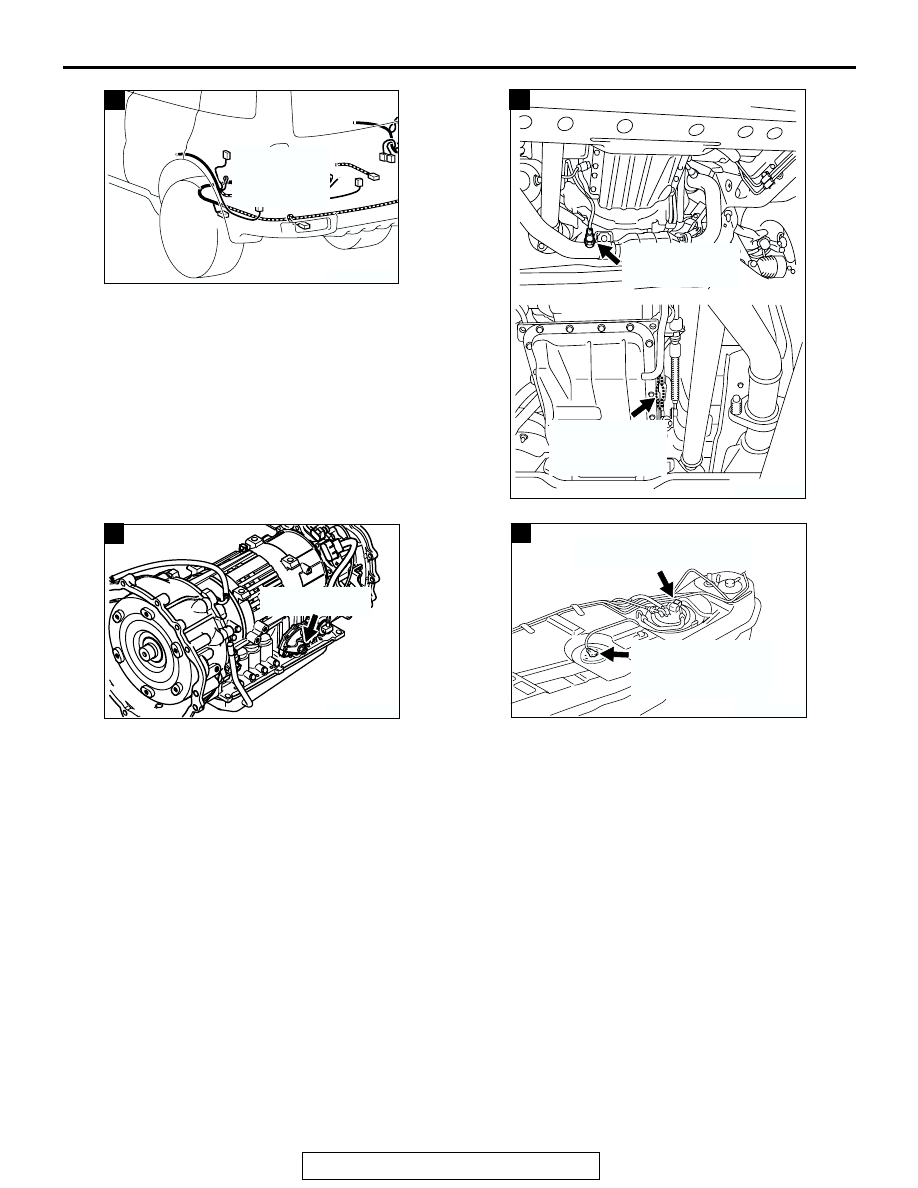

AK201059 AC

X

EVAPORATIVE

EMISSION

VENTILATION

SOLENOID

AK201275AC

RIGHT BANK

HEATED OXYGEN

SENSOR (REAR)

RIGHT BANK

HEATED OXYGEN

SENSOR (REAR)

CONNECTOR

Y

AK201288

TRANSMISSION

RANGE SWITCH

AC

Z

AK201308

FUEL SENSOR

(INCORPORATING

FUEL TEMPERATURE

SENSOR)

AB

a

FUEL TANK DIFFERENTIAL

PRESSURE SENSOR