Mitsubishi Montero (2002-2004). Manual - part 435

POWER STEERING GEAR BOX ASSEMBLY

TSB Revision

POWER STEERING

37A-27

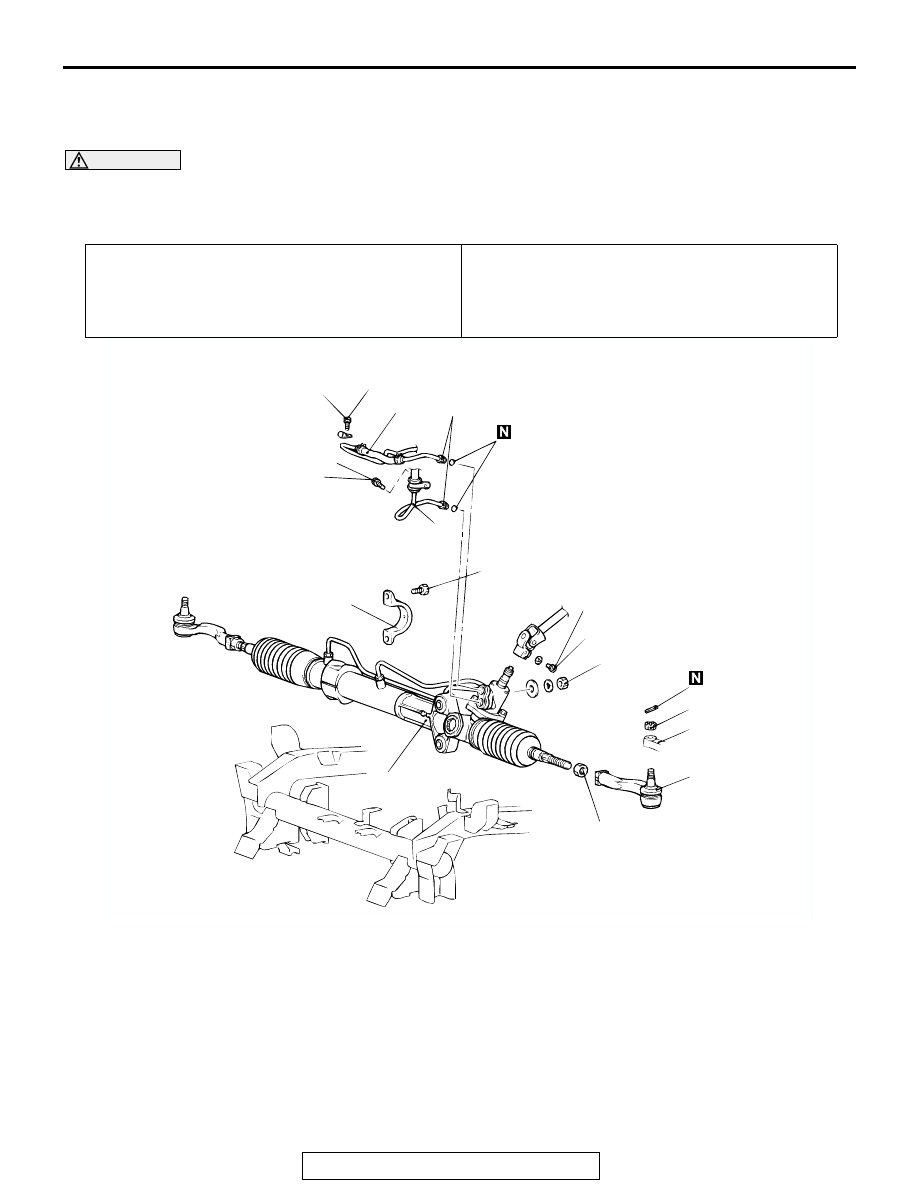

POWER STEERING GEAR BOX ASSEMBLY

REMOVAL AND INSTALLATION

M1372003900235

WARNING

Before removing the steering gear box, refer to GROUP 52B. Center the front wheels and

remove the ignition key. Failure to do so may damage the SRS clock spring and render the

SRS system inoperative, risking serious injury.

Required Special Tool:

• MB991897: Ball Joint Remover

Pre-removal Operation

Power Steering Fluid Draining (Refer to

.)

Post-installation Operation

• Fill power steering fluid and bleed air (Refer to

.)

• Check the Dust Cover for Cracks or Damage by Pushing

it with Your Finger.

• Check the steering angle (Refer to

AC000760

71

±

7 N

·

m

53

±

5 ft-lb

18

±

2 N

·

m

13

±

2 ft-lb

39

±

5 N

·

m

29

±

3 ft-lb

69

±

10 N

·

m

51

±

7 ft-lb

69

±

10 N

·

m

51

±

7 ft-lb

12

±

2 N

·

m

107

±

17 in-lb

12

±

2 N

·

m

107

±

17 in-lb

2

2

6

3

4

7

8

5

1

AB

15

±

3 N

·

m

11

±

2 ft-lb

REMOVAL STEPS

•

REMOVAL OF UNDER COVER

<<A>>

1. TIE ROD END AND KNUCKLE

CONNECTION

2. BOLT

>>B<<

3. PRESSURE HOSE ASSEMBLY

>>B<<

4. RETURN TUBE

>>A<<

5. TIE ROD END (LH)

<<B>>

•

INSTALLATION OF DIFFERENTIAL

MOUNT BRACKET (LH)

6. STEERING SHAFT ASSEMBLY AND

GEAR BOX CONNECTING BOLT

7. GEAR BOX CLAMP

<<C>>

8. GEAR BOX ASSEMBLY

REMOVAL STEPS (Continued)