Content .. 1137 1138 1139 1140 ..

Mitsubishi Montero (2002-2004). Manual - part 1139

M-ASTC DIAGNOSIS

TSB Revision

MITSUBISHI ACTIVE SKID AND TRACTION CONTROL SYSTEM

35C-173

CAUTION

Always use the test harness when measuring the voltage

or resistance value at the female connector. If you fail to do

so, connectors may be damaged.

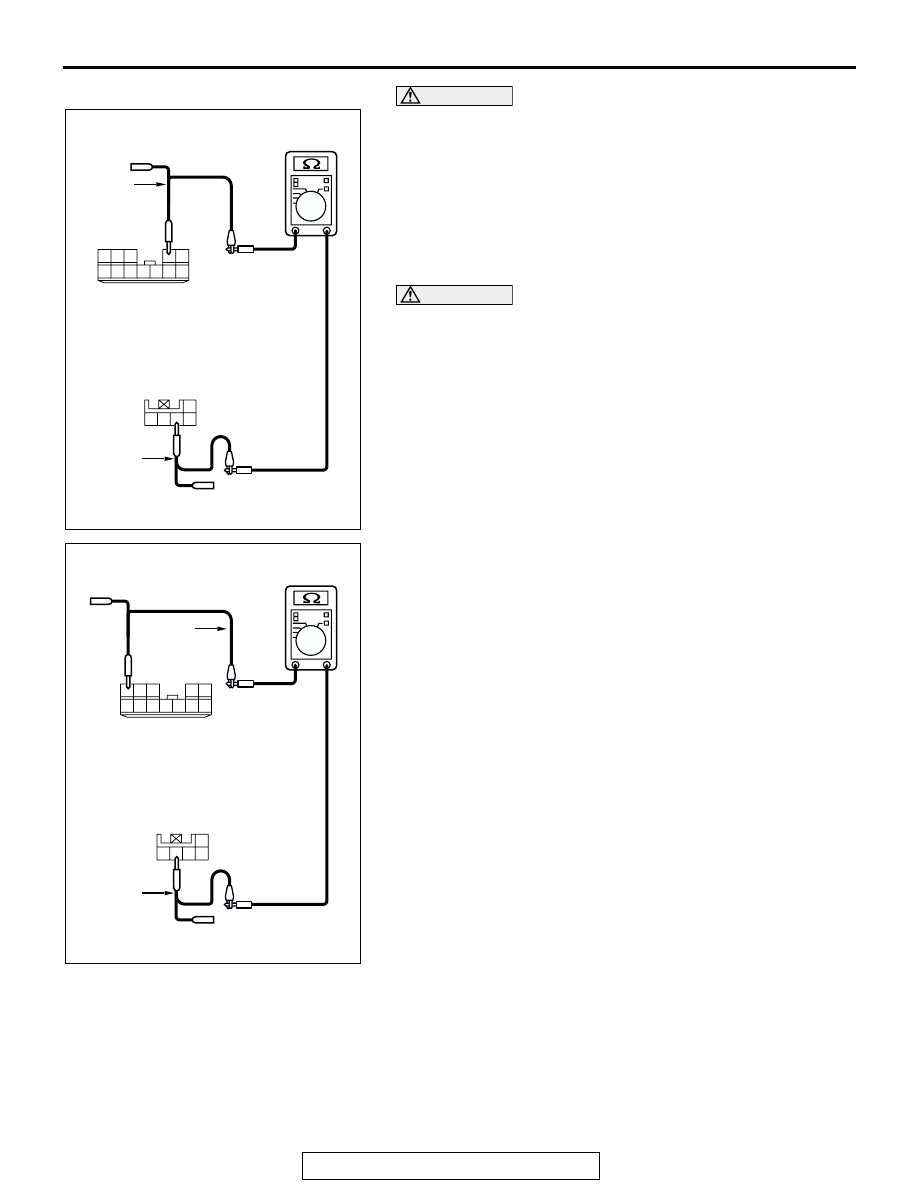

(4) Measure the resistance values between joint connector (9)

D-131 terminal 2 and steering wheel sensor connector D-

225 terminal 3, and between joint connector (9) D-131

terminal 5 and steering wheel sensor connector D-225

terminal 4.

• The resistance should measure 2 ohms or less.

CAUTION

If you repair the CAN bus line of the instrument panel wir-

ing harness assembly (the wiring harness connected to

the steering wheel sensor, the data link connector and the

resistor) and the transmission wiring harness assembly

(the wiring harness connected to the G and yaw rate sen-

sor connector and intermediate connector E-123), observe

the precautions regarding how to repair wiring harness. If

a new wire is added or a splice point is modified for the

CAN_L or CAN_H line, an error in the CAN communication

may be caused.

Q: Does the resistance measure 2 ohms or less?

YES : Diagnose the steering wheel sensor. Refer to

NO : Repair the wiring harness wires between joint

connector (9) and the steering wheel sensor

connector.

AC204582

HARNESS SIDE: D-225

AP

HARNESS SIDE: D-131

6

1

9 8

2

7

10

12 11

4

5

3

TEST

HARNESS

3 2

1

4

5

TEST

HARNESS

AC204582

HARNESS SIDE: D-225

AQ

HARNESS SIDE: D-131

6

1

9 8

2

7

10

12 11

4

5

3

TEST

HARNESS

3 2

1

4

5

TEST

HARNESS