Content .. 1138 1139 1140 1141 ..

Mitsubishi Montero (2002-2004). Manual - part 1140

M-ASTC DIAGNOSIS

TSB Revision

MITSUBISHI ACTIVE SKID AND TRACTION CONTROL SYSTEM

35C-177

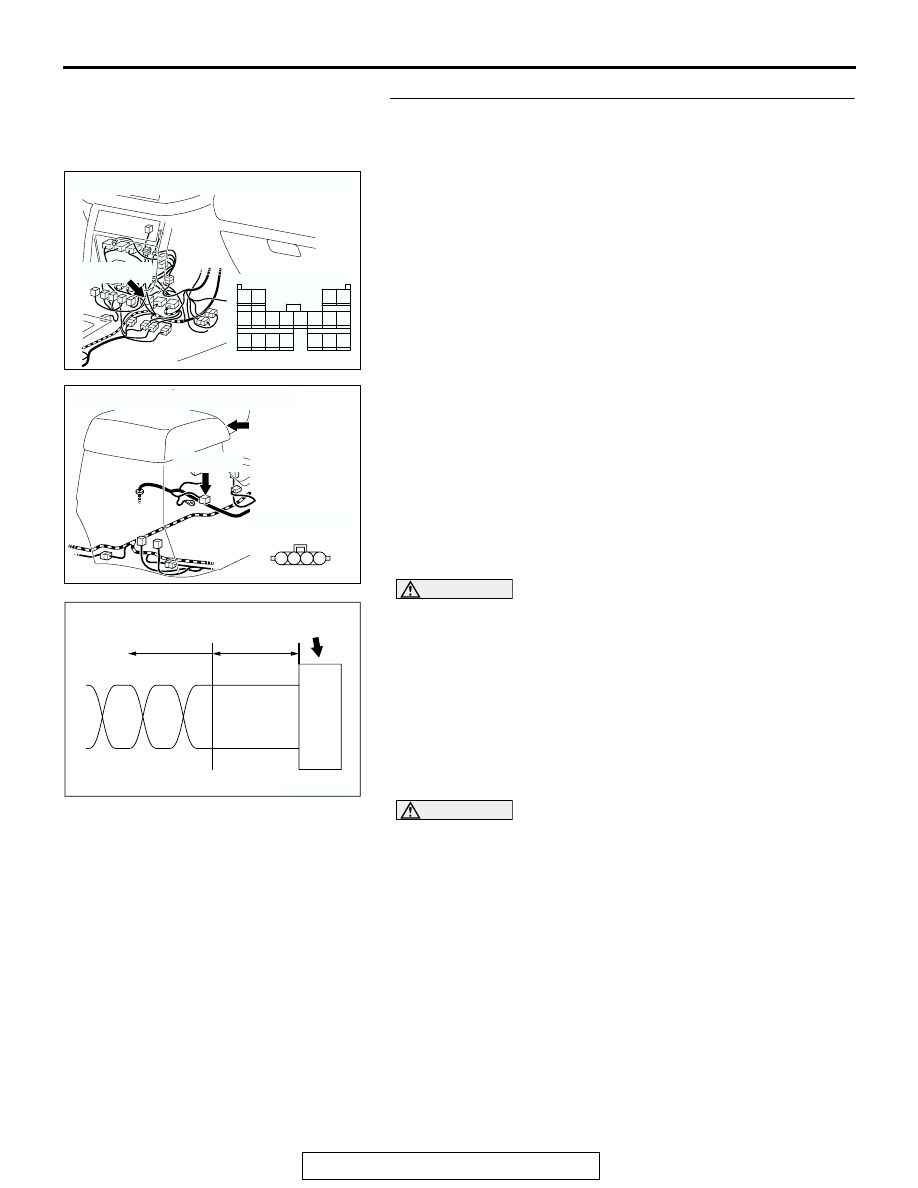

STEP 1. Check G and yaw rate sensor connector E-126 and

intermediate connector E-123.

CAUTION

If there is a problem in the connector(s) (including terminals) or

wire(s) of the instrument panel wiring harness assembly (the wir-

ing harness connected to the steering wheel sensor, the data

link connector and the resistor) and the transmission wiring har-

ness assembly (the wiring harness connected to the G and yaw

rate sensor connector and intermediate connector E-123), cut

and repair the defective wire so that the frayed end of the twisted

wire should be within 10 cm (4.0 inches). If it exceeds 10 cm (4.0

inches), twist the wiring harness just like the original twisted

wire. If the frayed end exceeds 10 cm (4.0 inches), a communica-

tion error may be caused.

CAUTION

If there is a problem in the CAN bus line or the connectors on the

control wiring harness assembly (the wiring harness connected

to the M-ASTC-ECU, the power control module and intermediate

connector E-123), do not attempt to repair the wiring harness or

connector(s), but replace the wiring harness assembly. If a wire

is added or the connector(s) are repaired, an error in the CAN

communication may be caused.

Q: Are G and yaw rate sensor connector E-126 and intermediate

connector E-123 in good condition?

YES : Go to Step 2.

NO :

• If there is a problem at the transmission wiring harness

assembly side, repair or replace the connector.

•

If there is a problem at the control wiring harness

assembly side, replace the control wiring harness

assembly.

AC204176

CONNECTOR: E-123

AR

E-123(GR)

2

6

14

7

9 8

10

4

12

3

11

19

16

1817

15

1

5

13

E-123(GR)

AC204175

CONNECTOR: E-126

HARNESS SIDE

E-126(GR)

E-126(GR)

AB

FLOOR

CONSOLE

1

2

4 3

AC203824

CONNECTOR

TWISTED WIRE

AB

10 cm

(4.0 inches)