Mitsubishi Montero (2002-2004). Manual - part 110

SPECIAL TOOLS

TSB Revision

AUTOMATIC AIR CONDITIONING

55B-133

SPECIAL TOOLS

M1554000600028

ON-VEHICLE SERVICE

CHARGING

M1552001200049

Use the refrigerant recovery station to charge the refrigerant.

METHOD BY USING REFRIGERANT RECOVERY

AND RECYCLING UNIT

Using the refrigerant recovery and recycling unit, refill the

refrigerant.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit

Instruction Manual for operation of the unit.

DISCHARGING SYSTEM

Use the refrigerant recovery unit to discharge refrigerant gas

from the system.

NOTE: Refer to the Refrigerant Recovery and Recycling Unit

Instruction Manual for operation of the unit.

TOOL

TOOL NUMBER AND

NAME

SUPERSESSION

APPLICATION

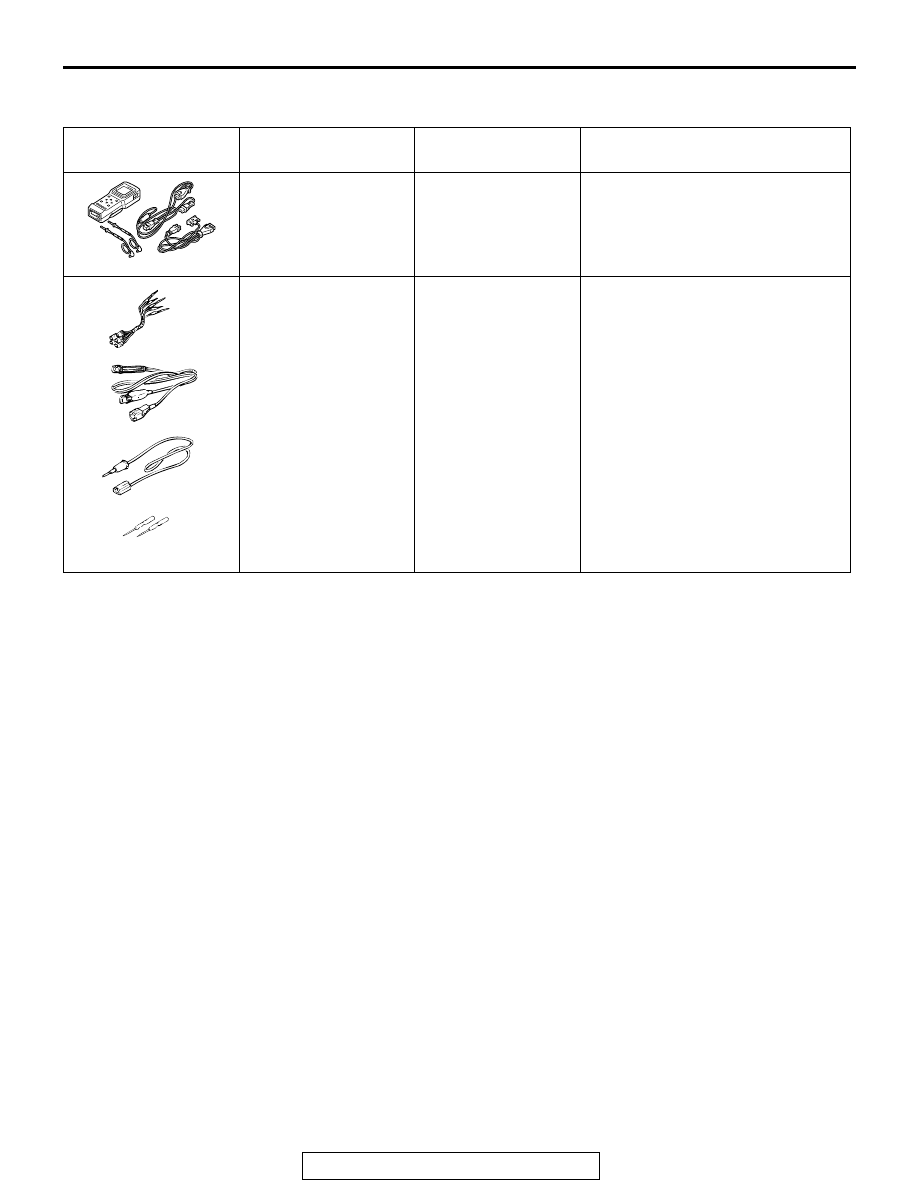

MB991502 Scan tool

(MUT-II)

MB991496-OD

Diagnostic trouble code check

MB991223

Harness set

A: Connector pin

contact pressure

check

B: Power circuit check

C: Power circuit check

D: Commercial tester

connection

MB991223

MB991709-01

Continuity check and voltage

measurement at the harness

connector

A: Connector pin contact pressure

check

B: Power circuit check

C: Power circuit check

D: Commercial tester connection

B991502

MB991223

A

AB

B

C

D