Content .. 1086 1087 1088 1089 ..

Mitsubishi Montero (2002-2004). Manual - part 1088

STARTING SYSTEM

TSB Revision

ENGINE ELECTRICAL

16-25

INSPECTION

M1162001300049

.

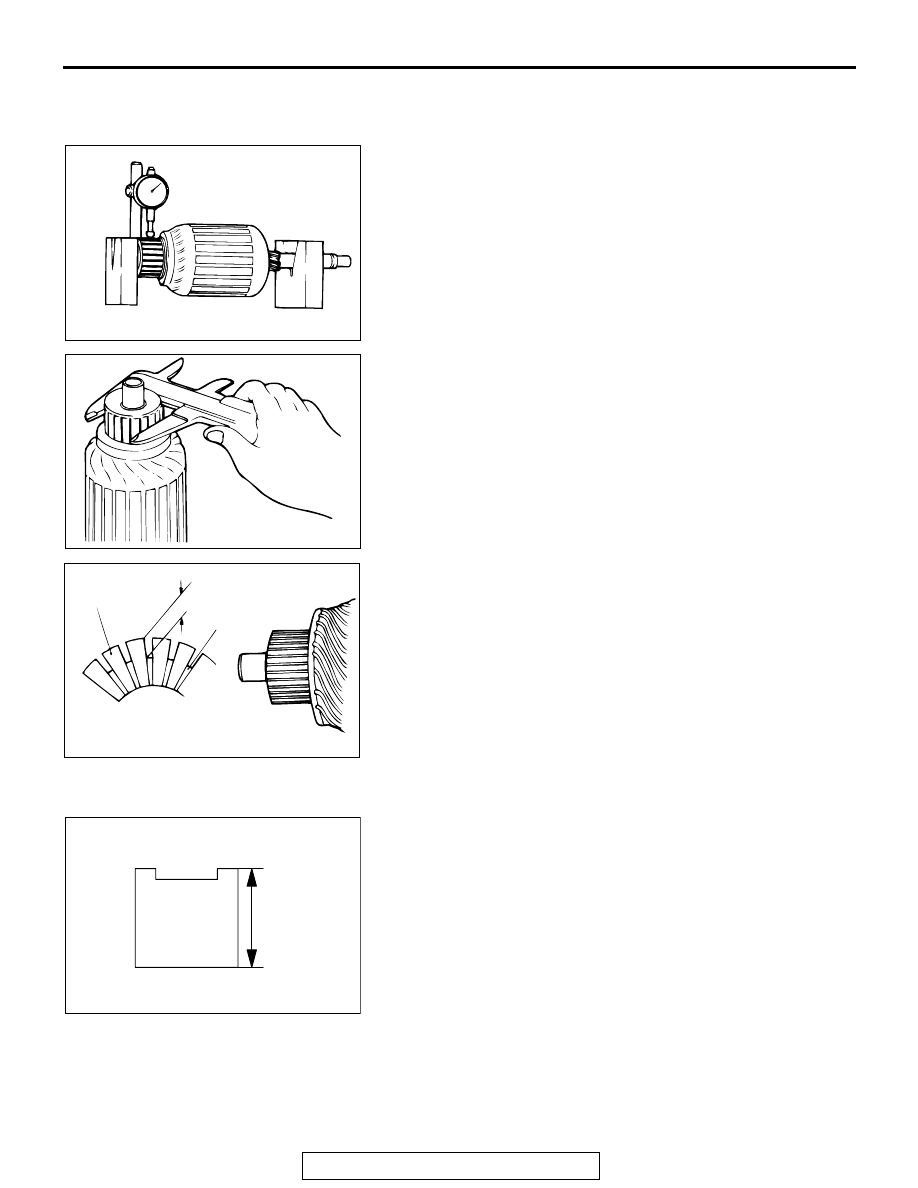

COMMUTATOR CHECK

1. Place the armature on a pair of V-blocks, and check the

deflection by using a dial gauge.

Standard value: 0.05 mm (0.002 inch)

Limit: 0.1 mm (0.004 inch)

2. Check the outer diameter of the commutator.

Standard value: 29.4 mm (1.16 inches)

Minimum limit: 28.8 mm (1.13 inches)

3. Check the depth of the undercut between segments.

Standard value: 0.5 mm (0.02 inch)

Minimum limit: 0.2 mm (0.008 inch)

.

BRUSH CHECK

1. Check the brush for roughness of the surface that contacts

the commutator and check the brush length.Replace the

brush holder if this measurement exceeds the limit.

Minimum limit: 7.0 mm (0.28 inch)

2. .In the case contacting surface has been corrected or the

brush has been replaced, correct the contacting surface by

winding sandpaper around the commutator

.

AKX00373

AKX00374

AKX00375

SEGMENT

UNDERCUT

MICA

AB

AK101390

LIMIT LENGTH

AB