Mitsubishi Montero (2002-2004). Manual - part 35

GENERAL DESCRIPTION

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55A-3

.

GENERAL DESCRIPTION

M1551000100080

The heater system uses a two-way-flow full-air-mix

system that features high performance and low oper-

ating noise. The air conditioning (A/C) system is

basically the same as the conventional system, but a

new refrigerant system has been adopted as a

response to restrictions on the use of chlorofluoro-

carbons.

SAFETY PRECAUTIONS

WARNING

Wear safety goggles when servicing the

refrigeration system to prevent severe dam-

age to hands.

Because R134a refrigerant is a hydro fluorocarbon

(HFC) which contains hydrogen atoms in place of

chlorine atoms, it will not cause damage to the ozone

layer. Ozone filters out harmful radiation from the

sun. To assist in protecting the ozone layer,

Mitsubishi Motors Corporation recommends an

R134a refrigerant recycling device. Refrigerant

R134a is transparent and colorless in both the liquid

and vapor state. Since it has a boiling point of

− 29.8

°C(− 21.6 °F) at atmospheric pressure, it will be a

vapor at all normal temperatures and pressures. The

vapor is heavier than air, non-flammable, and non-

explosive. The following precautions must be

observed when handling R134a.

WARNING

Do not heat R134a above 40

°C (104°F) or it

may catch fire and explode.

R134a evaporates so rapidly at normal atmospheric

pressures and temperatures that it tends to freeze

anything it contacts. For this reason, extreme care

must be taken to prevent any liquid refrigerant from

contacting the skin and especially the eyes. Always

wear safety goggles when servicing the refrigeration

part of the A/C system. Keep a bottle of sterile min-

eral oil handy when working on the refrigeration sys-

tem.

1. Should any liquid refrigerant get into the eyes, use

a few drops of mineral oil to wash them out.

R134a is rapidly absorbed by the oil.

2. Next splash the eyes with plenty of cold water.

3. Call your doctor immediately even though irritation

has ceased after treatment.

CAUTION

Keep R134a containers upright when charging

the system.

In most instances, moderate heat is required to bring

the pressure of the refrigerant in its container above

the pressure of the system when charging or adding

refrigerant. A bucket or large pan of hot water not

over 40

°C (104 °F) is all the heat required for this

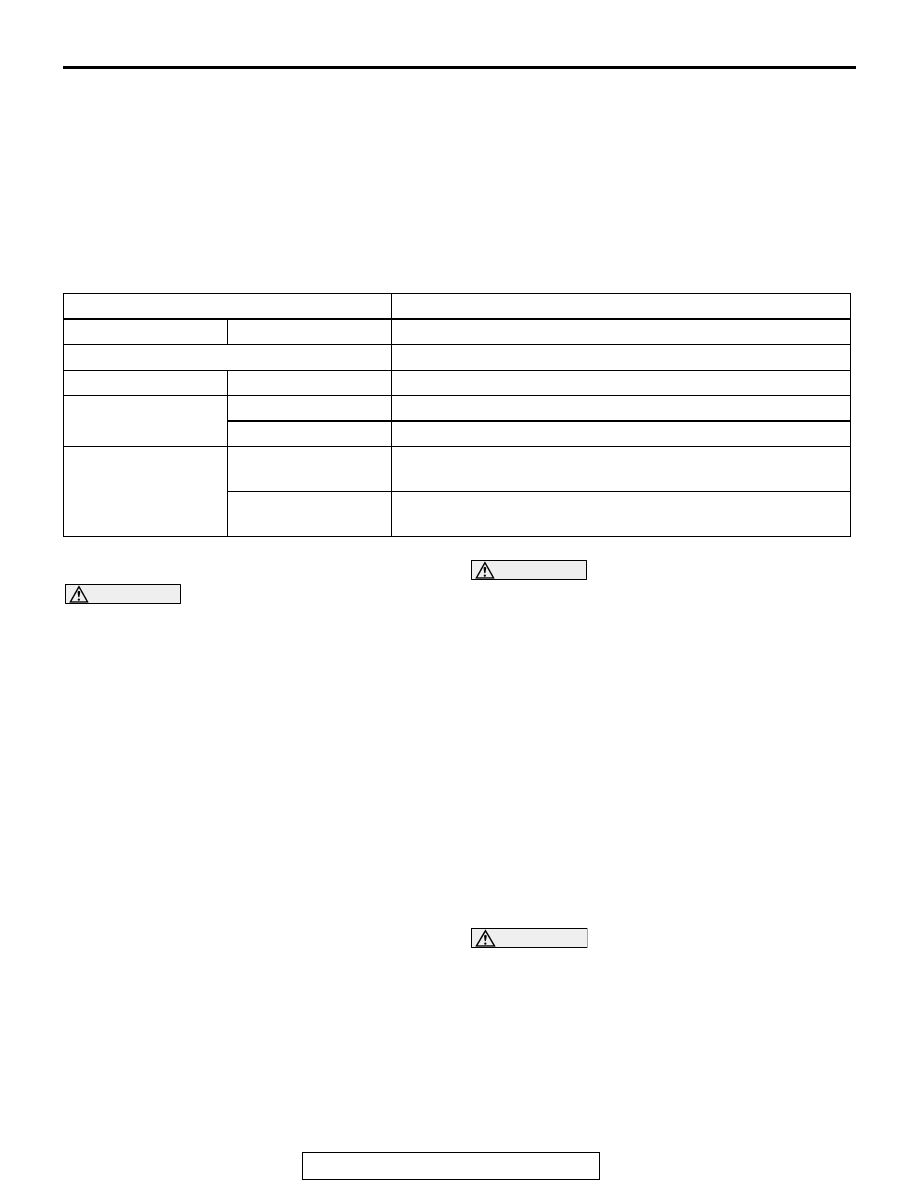

ITEMS

SPECIFICATIONS

Heater unit

Type

Two-way-flow full-air-mix system

Heater control assembly

Dial type

Compressor

Model

10S17C

Dual pressure switch

kPa (psi)

High-pressure switch ON to OFF: 3,140 (455.5), OFF to ON: 2,550(369.9)

Low-pressure switch ON to OFF: 196 (28.4), OFF to ON: 223 (32.4)

Refrigerant and

quantity g (oz)

Vehicles without rear

A/C or rear cooler

R134a (HFC-134a), Approximately 530

− 570 (18.7 − 20.1)

Vehicles with rear A/

C or rear cooler

R134a (HFC-134a), Approximately 730

− 770 (26.1 − 27.1)