Mitsubishi Montero (1998+). Manual - part 33

ADJUSTMENTS

* PLEASE READ FIRST *

NOTE: For adjustment information on brake pedal height, free play,

parking brake and stoplight switch, see BRAKE SYSTEM article.

WHEEL SPEED SENSOR (WSS)

NOTE: Rear WSS gap adjustment information is not available from

manufacturer.

Front WSS-To-Rotor Gap Adjustment

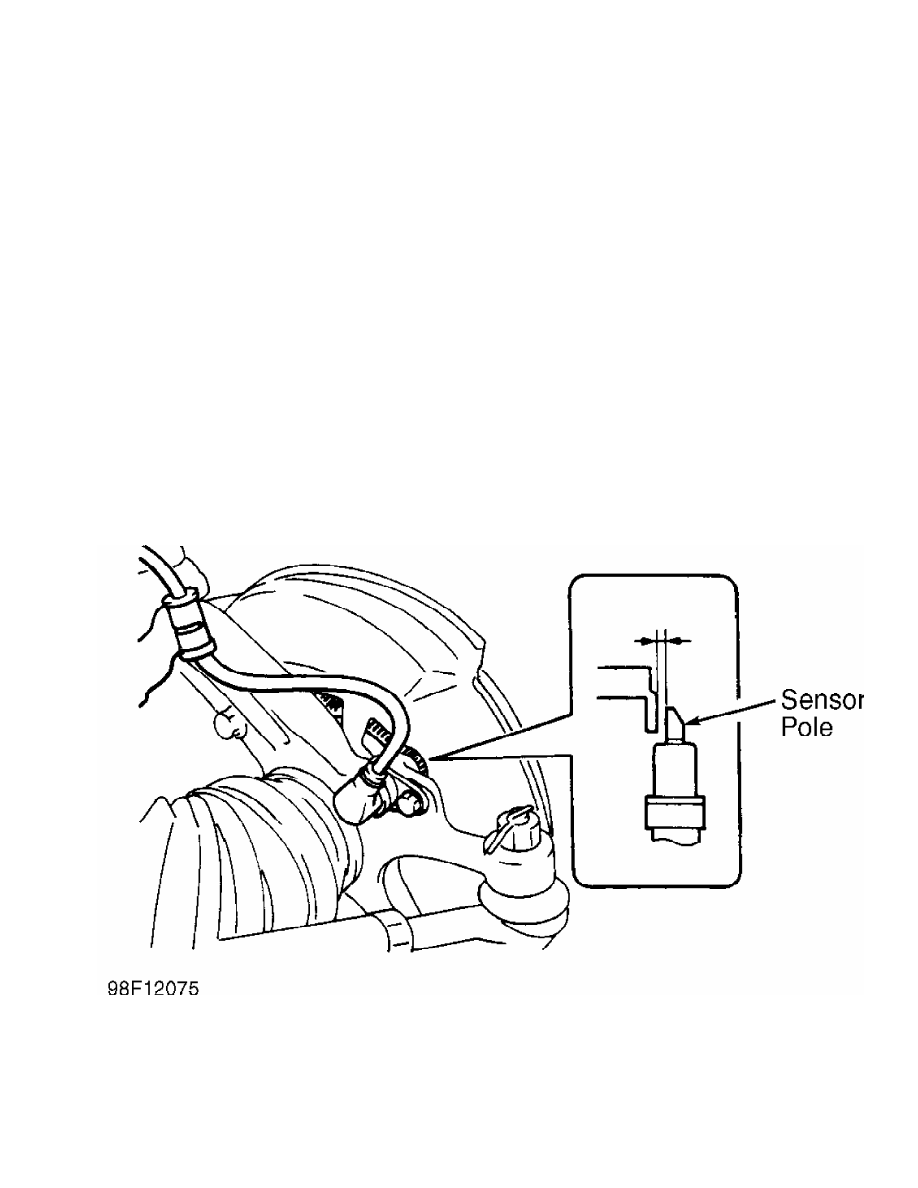

1) Raise and support vehicle. Remove wheel(s). Inspect sensor

pole piece for damage. Repair if necessary. If sensor pole piece is

okay, check WSS-to-rotor gap.

2) Using a feeler gauge, check clearance between sensor pole

and rotor tooth surface. See Fig. 1. Front WSS sensor clearance should

be .008-.390" (0.2-1.0 mm). If clearance is not as specified, loosen

sensor mounting bolt. Adjust sensor position until clearance is within

specification. Tighten sensor mounting bolt to specification. See

TORQUE SPECIFICATIONS.

Fig. 1: Checking Front WSS-To-Rotor Gap

Courtesy of Mitsubishi Motor Sales of America.

TROUBLE SHOOTING

ANTI-LOCK WARNING LIGHT

1) Turn ignition on. ANTI-LOCK warning light should come on