Mitsubishi Galant (2004+). Manual - part 900

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI) <2.4L ENGINE>

13A-417

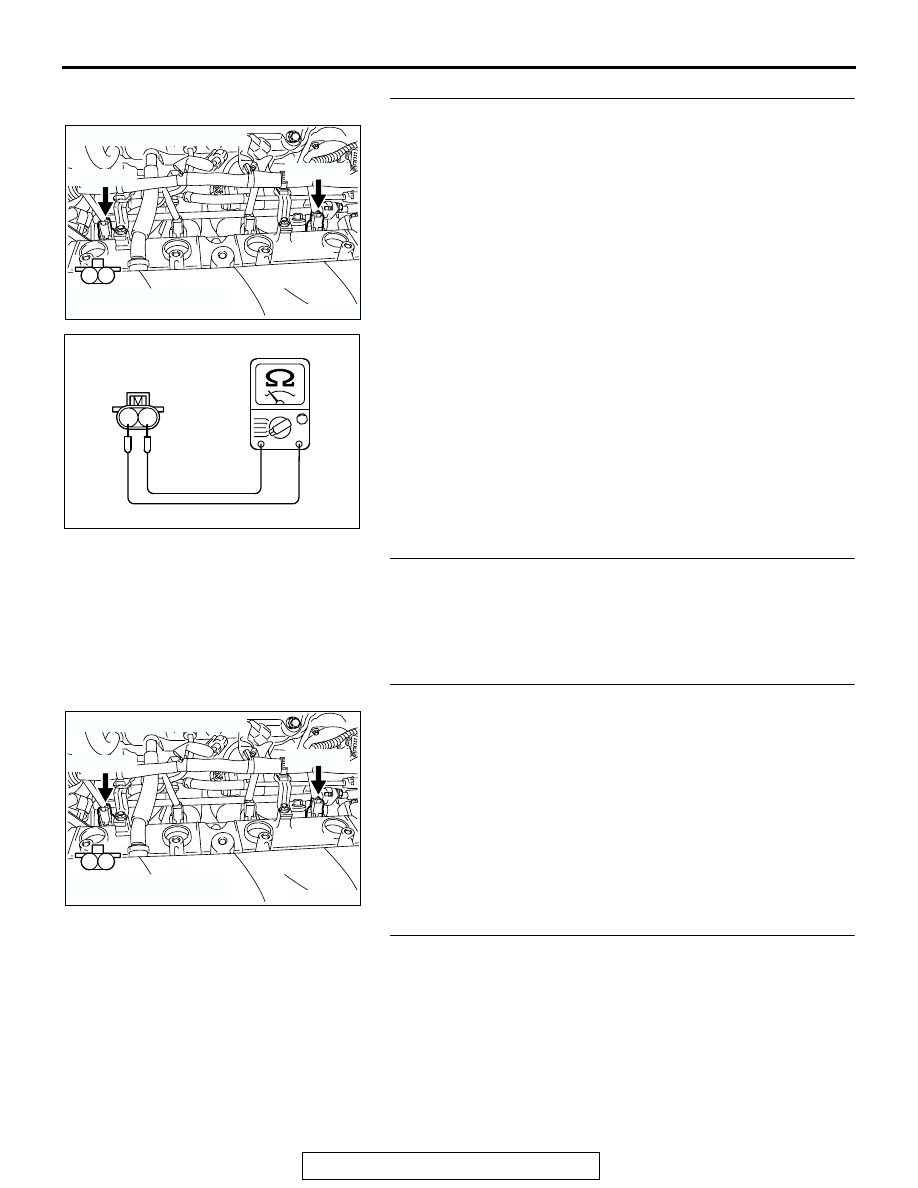

STEP 6. Check the cylinder 1, 4 injector.

(1) Disconnect the cylinder 1, 4 injector connector B-01, B-27.

(2) Measure the resistance between each injector side

connector terminal No. 1 and No. 2.

Standard value: 10.5

− 13.5 ohms [at 20°C (68°F)]

Q: Is the measured resistance between 10.5 and 13.5 ohms

[at 20

°C (68°F)]?

YES : Go to Step 7.

NO : Replace the injector. Then go to Step 9.

STEP 7. Check the fuel pressure.

Refer to On-vehicle Service

− Fuel Pressure Test

Q: Is the fuel pressure normal?

YES : Repair it. Then go to Step 9.

NO : Go to Step 8.

STEP 8. Replace the cylinder 1, 4 injector.

(1) Replace the cylinder 1, 4 injector.

(2) Carry out a test drive with the drive cycle pattern. Refer to

Diagnostic Function

− OBD-II Drive Cycle − Procedure 2 −

Fuel Trim Monitor

(3) Check the diagnostic trouble code (DTC).

Q: Is DTC P0172 set?

YES : Replace the PCM. Then go to Step 9.

NO : The inspection is complete.

STEP 9. Test the OBD-II drive cycle.

(1) Carry out a test drive with the drive cycle pattern. Refer to

Diagnostic Function

− OBD-II Drive Cycle − Procedure 2 −

Fuel Trim Monitor

(2) Check the diagnostic trouble code (DTC).

Q: Is DTC P0172 set?

YES : Retry the troubleshooting.

NO : The inspection is complete.

M

1

2

AK303822

B-01 (GR)

B-27 (GR)

CONNECTORS: B-01, B-27

AB

HARNESS CONNECTOR:

COMPONENT SIDE

AK000559

2

1

INJECTOR SIDE

CONNECTOR

AB

M

1

2

AK303822

B-01 (GR)

B-27 (GR)

CONNECTORS: B-01, B-27

AB

HARNESS CONNECTOR:

COMPONENT SIDE