Mitsubishi Galant (2004+). Manual - part 540

ON-VEHICLE SERVICE

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-105

3. Manually turn the wheel to be measured 1/2 to 1

turn/second. Measure the output voltage with a voltmeter or

oscilloscope.

NOTE: Check the connection of the sensor harness and

connector before using the oscilloscope.

Output voltage:

• Minimal voltmeter reading: 42 mV

• Maximum voltmeter reading: 300 mV

• Minimal oscilloscope reading: 120 mV

• Maximum oscilloscope reading: 600 mV

Probable causes of low output voltage

• Wheel speed sensor pole piece-to-wheel speed rotor clear-

ance too large

• Faulty wheel speed sensor

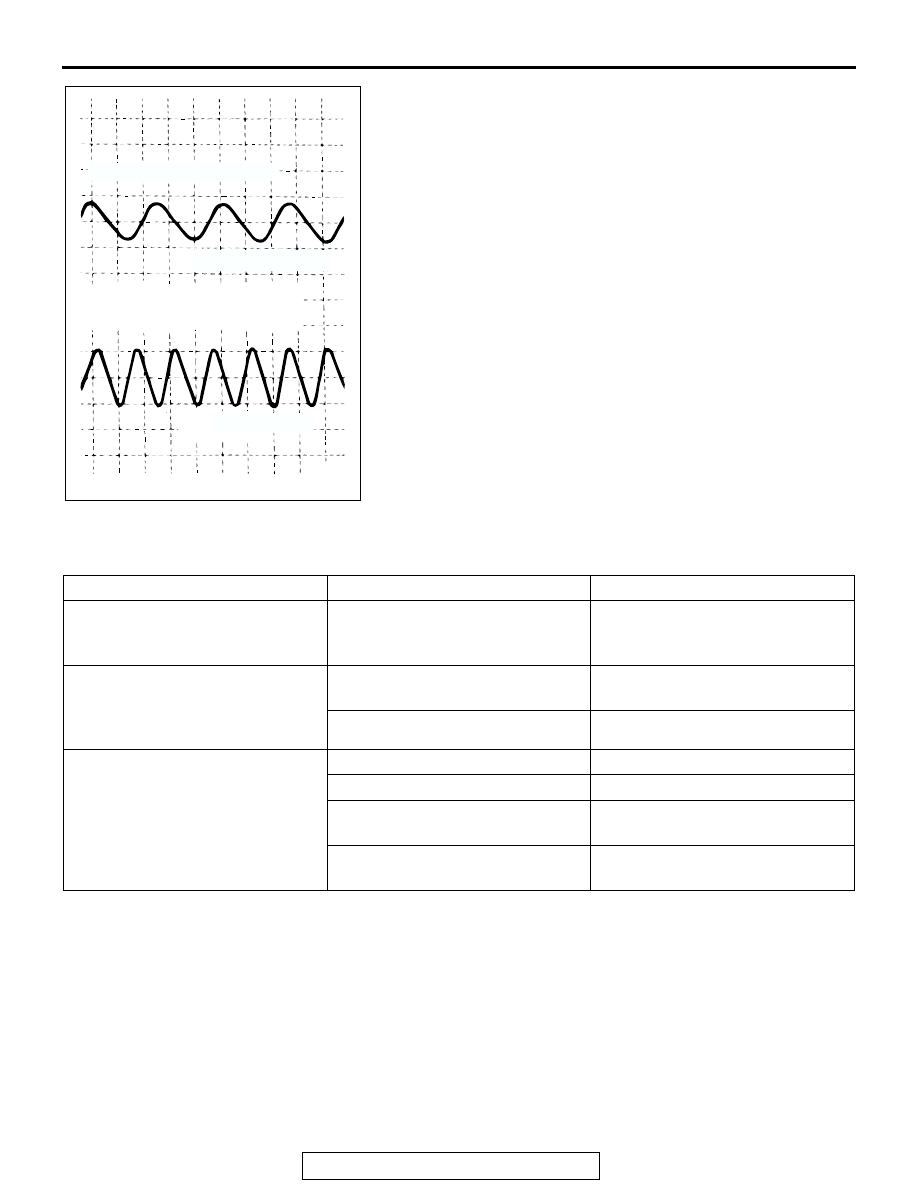

4. To observe the waveform with an oscilloscope:

• Front Wheels: Shift into "D" range and drive the wheels.

• Rear Wheels: Turn the wheels manually at a constant

speed

NOTE: The output waveform is low when the wheel speed is

low. Similarly, it will be higher as the wheel speed increases.

Waveform may also be observed by driving the vehicle.

.

POINTS IN WAVEFORM MEASUREMENT

NOTE: The wheel speed sensor cable moves in relation to motion of the front or rear suspension. Therefore,

it is likely that it has an open circuit only when driving on rough roads but it functions normally when driving on

smooth roads. It is recommended to observe sensor output voltage waveform also under special conditions,

such as driving on a rough road.

AC000949 AC

WHEN TURNED MANUALLY

IN "D" RANGE, IDLING

[5

− 6 km/h (3 − 4 mph)]

[10.0 ms/DIV 1 V/DIV]

[10.0 ms/DIV 1 V/DIV]

SYMPTOM

PROBABLE CAUSE

REMEDY

Too small or zero waveform

amplitude

Faulty wheel speed sensor or

excessive gap between it and the

wheel speed rotor

Replace wheel speed sensor

Waveform amplitude fluctuates

excessively (This is no problem if

the minimum amplitude is 100 mV

or more)

Axle hub eccentric or with large

runout

Replace hub assembly

Faulty ABS-ECU ground

Repair harness wires

Noisy or disturbed waveform

Open circuit in wheel speed sensor Replace wheel speed sensor

Open circuit in harness

Repair harness wire

Incorrectly mounted wheel speed

sensor

Mount wheel speed sensor

correctly

Wheel speed rotor with missing or

damaged teeth

Replace wheel speed rotor