Mitsubishi Galant (2004+). Manual - part 538

ANTI-LOCK BRAKING SYSTEM (ABS) DIAGNOSIS

TSB Revision

ANTI-LOCK BRAKING SYSTEM (ABS)

35B-97

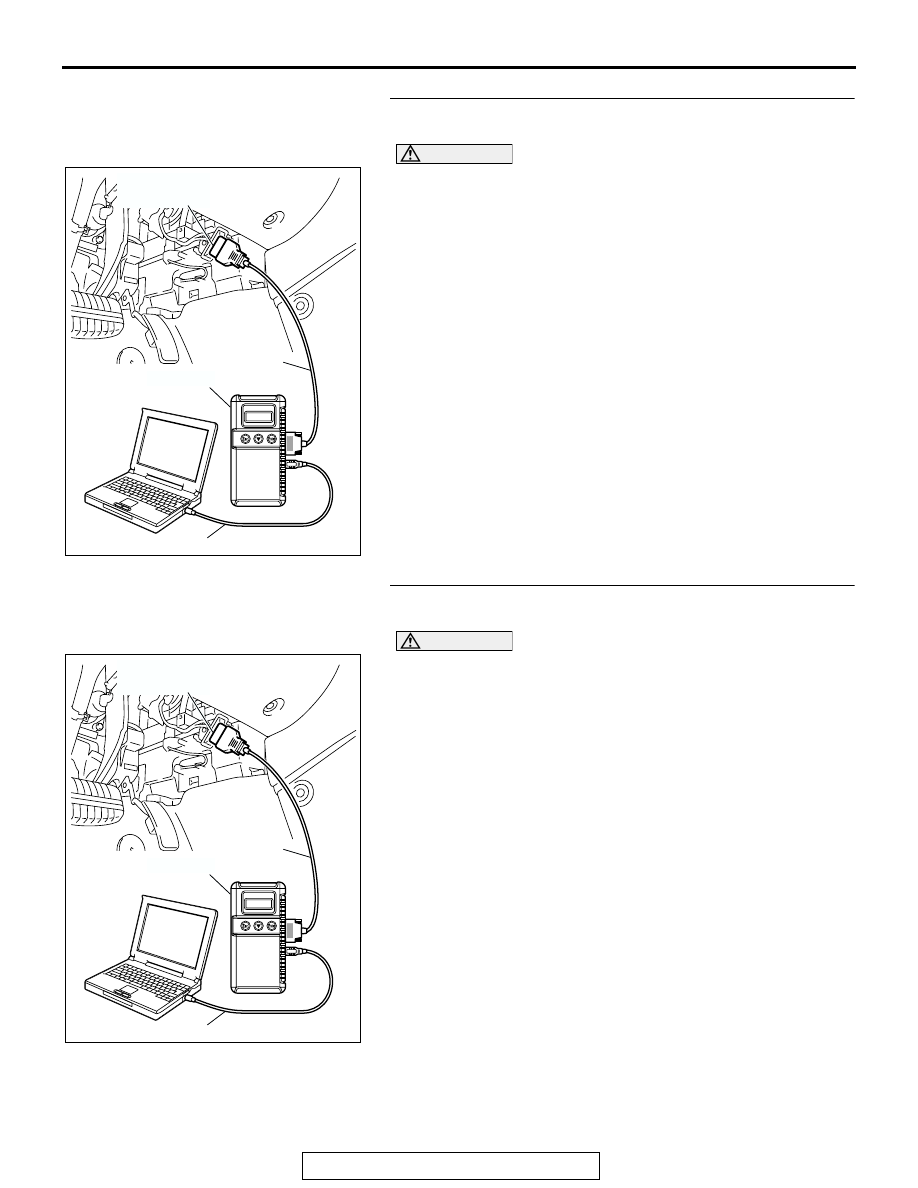

STEP 1. Using scan tool MB991958, diagnose the CAN bus

line.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

Use scan tool MB991958 to diagnose the CAN bus lines.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Diagnose the CAN bus line.

Q: Is the check result satisfactory?

YES : Go to Step 2.

NO : Repair the CAN bus lines (Refer to GROUP 54C,

Diagnosis-CAN Bus Diagnostic Chart

Repair the CAN bus lines, and then go to Step 2.

STEP 2. Using scan tool MB991958, read the combination

meter diagnostic trouble code.

CAUTION

To prevent damage to scan tool MB991958, always turn the

ignition switch to the "LOCK" (OFF) position before con-

necting or disconnecting scan tool MB991958.

Use scan tool MB991958 to check whether combination meter

DTC U1102 has been set.

(1) Connect scan tool MB991958 to the data link connector.

(2) Turn the ignition switch to the "ON" position.

(3) Check whether combination meter DTC U1102 has been

set.

Q: Is combination meter DTC U1102 set?

YES : Replace the hydraulic unit (integrated with

ABS-ECU).

NO : Replace the combination meter.

AC305412

AB

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827

AC305412

AB

MB991910

DATA LINK

CONNECTOR

MB991824

MB991827