Mitsubishi Galant (2004+). Manual - part 508

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-19

CAUTION

Do not wipe off the special grease that is on the lock pin.

Do not contaminate the lock pin.

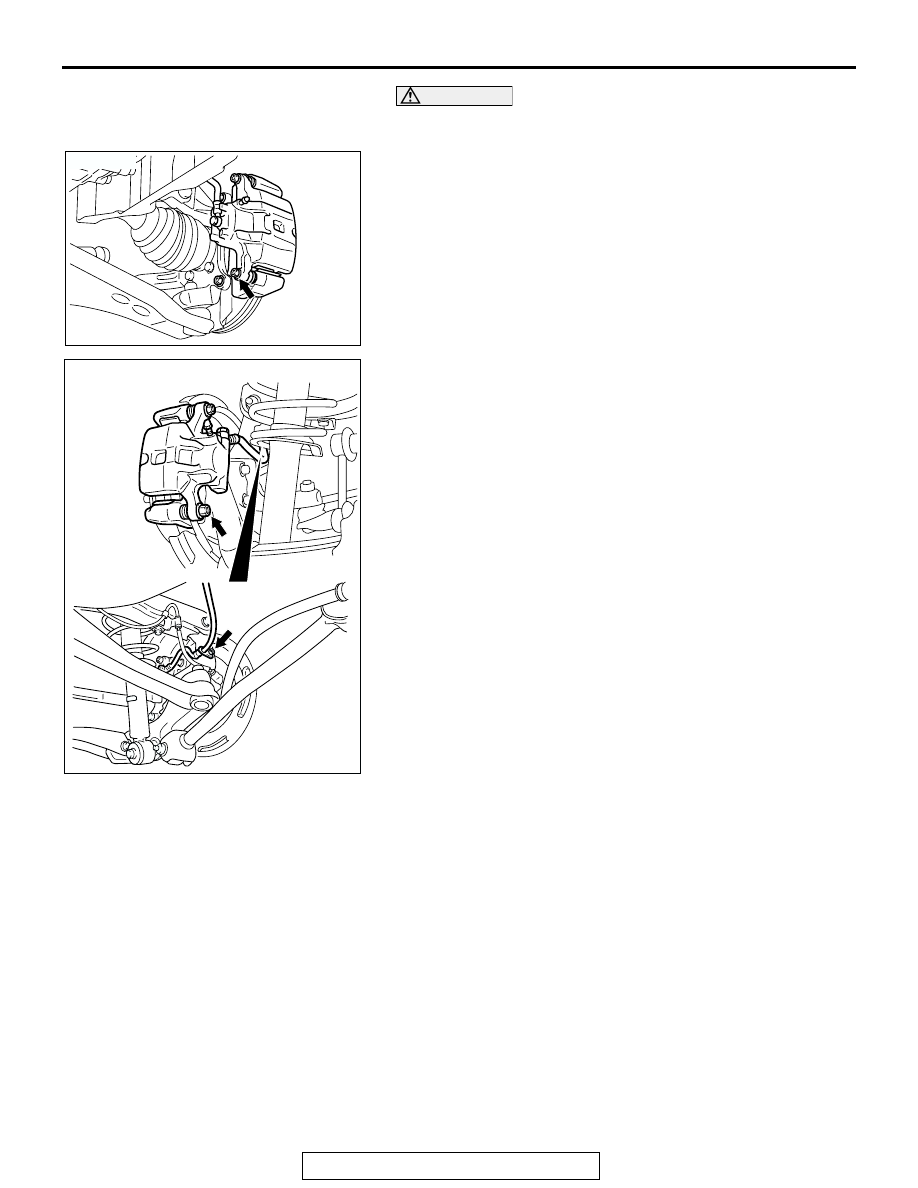

2. Remove the lock pin bolt <Front> or lock pin and brake hose

clamp <Rear>. Pivot the caliper assembly and hold it with

wires.

AC305371

AC

<FRONT>

AC307348

AB

<REAR>