Mitsubishi Galant (2004+). Manual - part 146

TIMING BELT

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-57

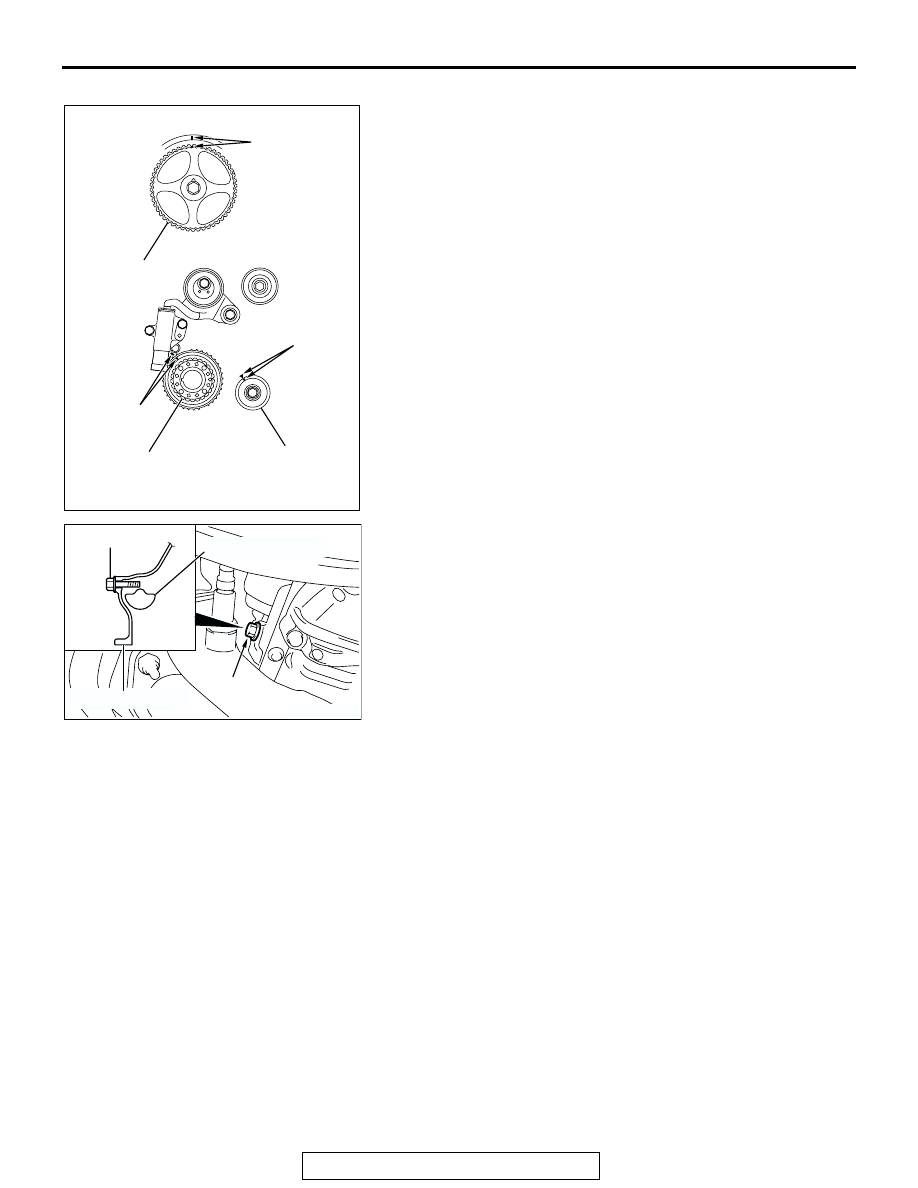

>>F<< VALVE TIMING BELT INSTALLATION

1. Align the timing marks on the camshaft sprocket, crankshaft

camshaft drive sprocket and engine oil pump sprocket.

2. Adjust the timing mark of the engine oil pump sprocket.

Unplug the cylinder block plug. Insert a bolt (M6, section

width 10 mm, nominal length 45 mm) from the plug hole. If

the bolt comes in contact with the balancer shaft, turn the

engine oil sprocket one rotation. Re-adjust the timing mark

and then check to see that the bolt fits. Do not remove the

bolt until the valve timing belt is assembled.

AC301374

AB

TIMING MARK

TIMING

MARK

TIMING

MARK

CAMSHAFT

SPROCKET

CRANKSHAFT

CAMSHAFT

DRIVE SPROCKET

ENGINE OIL

PUMP SPROCKET

AC301871AB

PLUG

BOLT

BALANCERSHAFT

CYLINDER BLOCK