Content .. 1379 1380 1381 1382 ..

Mitsubishi Galant (2004+). Manual - part 1381

FRONT SUSPENSION DIAGNOSIS

TSB Revision

FRONT SUSPENSION

33-3

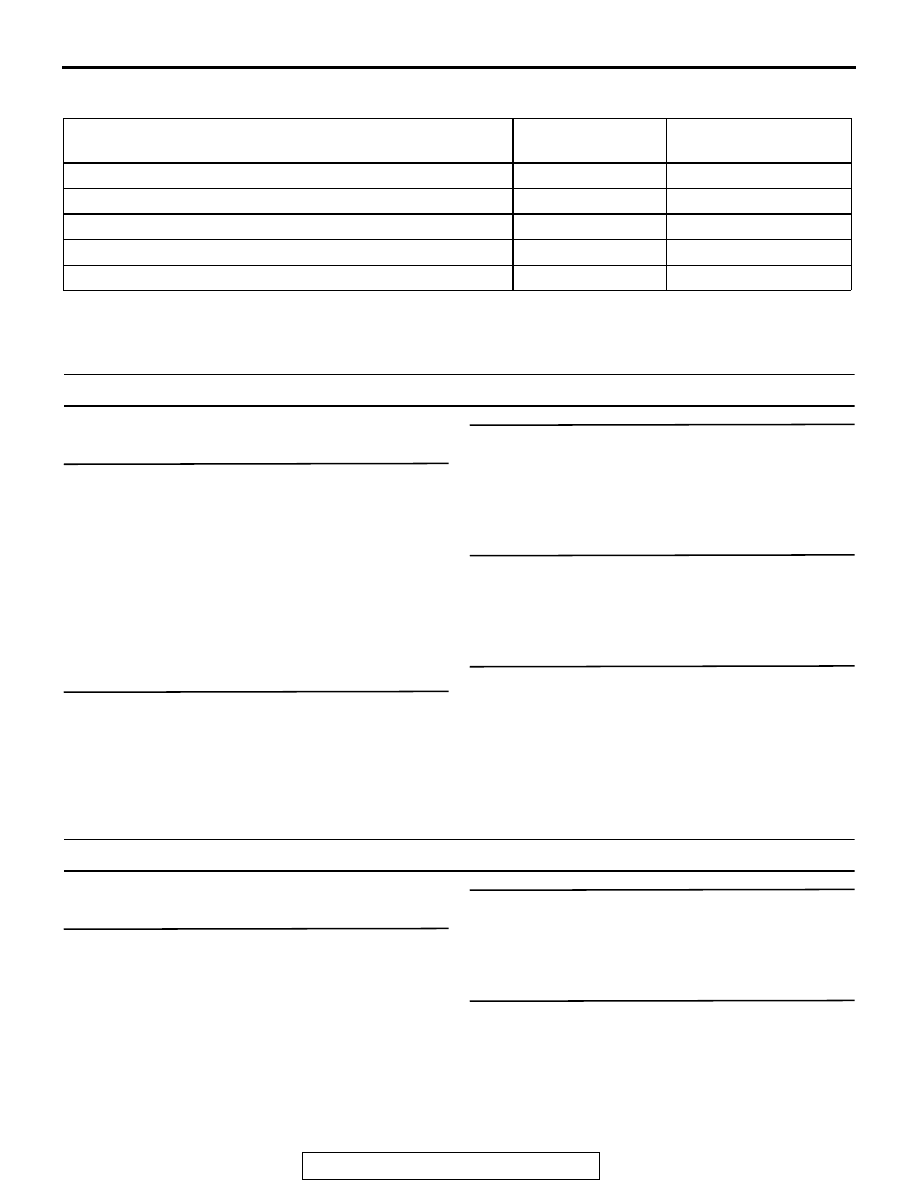

SYMPTOM CHART

M1332009400290

SYMPTOM PROCEDURES

INSPECTION PROCEDURE 1: Steering Wheel is Heavy, Vibrates or Pulls to One Side

DIAGNOSIS

STEP 1. Check the tires.

Check for the tire pressure, the tire pressure balance

between left and right tires, and the tire condition.

Refer to GROUP 31, Diagnosis

Q: Are the tires in normal condition?

YES :

Go to Step 2.

NO :

If out of pressure, adjust the tire pressure. If

out of balance, balance the tires as

necessary. If excessively worn, replace the

tires as necessary and then go to Step 5.

STEP 2. Check the wheel alignment.

Refer to

Q: Is the wheel alignment correct?

YES :

Go to Step 3.

NO :

Adjust it, and then go to Step 5.

STEP 3. Check the lower arm ball joint.

Q: Is the ball joint in good condition?

YES :

Go to Step 4.

NO :

Replace the lower arm assembly, and then

go to Step 5.

STEP 4. Check the coil spring.

Q: Is the coil spring in good condition?

YES :

Go to Step 5.

NO :

Replace it, and then go to Step 5.

STEP 5. Retest the system.

Q: Is the malfunction eliminated?

YES :

The procedure is complete.

NO :

Return to Step 1.

INSPECTION PROCEDURE 2: Excessive Body Rolling

DIAGNOSIS

STEP 1. Check for broken or deteriorated

stabilizer bar.

Q: Is the stabilizer bar in good condition?

YES :

Go to Step 2.

NO :

Replace it, and then go to Step 3.

STEP 2. Check the strut assembly for damage.

Q: Is the strut assembly in good condition?

YES :

Go to Step 3.

NO :

Replace it, and then go to Step 3.

STEP 3. Retest the system.

Q: Is the malfunction eliminated?

YES :

The procedure is complete.

NO :

Return to Step 1.

SYMPTOM

INSPECTION

PROCEDURE

REFERENCE PAGE

Steering wheel is heavy, vibrates or pulls to one side

1

Excessive body rolling

2

Poor ride

3

Unequal ride height

4

Noise

5