Mitsubishi Galant (2004+). Manual - part 137

ENGINE ASSEMBLY

TSB Revision

ENGINE MECHANICAL <2.4L ENGINE>

11A-21

REMOVAL SERVICE POINTS

.

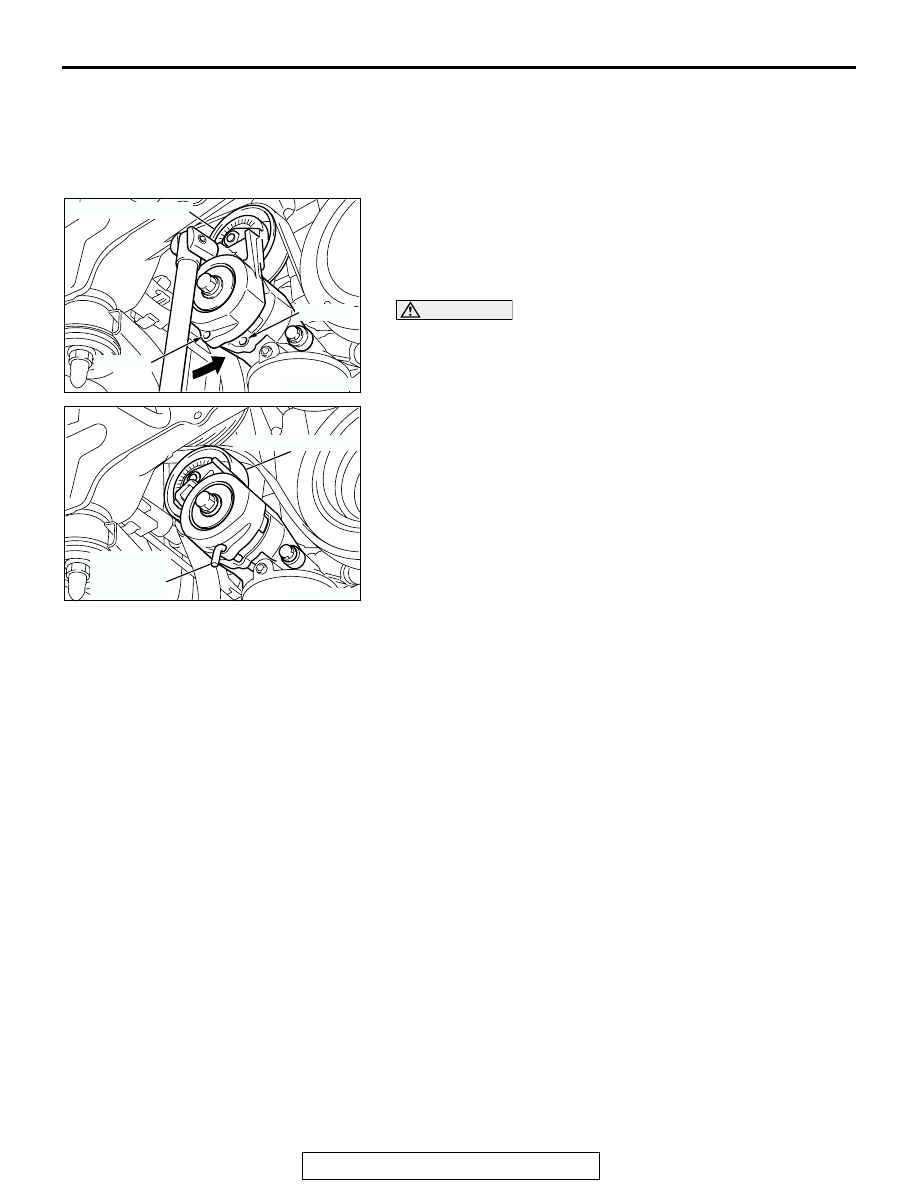

<<A>> DRIVE BELT REMOVAL

The following operations will be needed due to the introduction

of the serpentine drive system with the drive belt auto-ten-

sioner.

1. Securely insert the spindle handle or ratchet handle with a

12.7 mm (1/2-inch) insertion angle into the jig hole of the

auto-tensioner.

2. Rotate the auto-tensioner counterclockwise and align hole A

with hole B.

CAUTION

To reuse the drive belt, draw an arrow indicating the rotat-

ing direction (clockwise) on the back of the belt using

chalk, etc.

3. Insert an L-shaped hexagon wrench, etc. into the hole to fix

and then remove the drive belt.

.

<<B>> POWER STEERING OIL PUMP AND BRACKET

ASSEMBLY REMOVAL

With the hose installed, remove the power steering oil pump

and bracket assembly from the engine assembly.

NOTE: After removing the power steering oil pump and bracket

assembly, secure it with a cord in the location where the

removal and installation of the engine assembly cannot be hin-

dered.

.

<<C>> A/C COMPRESSOR AND CLUTCH ASSEMBLY

REMOVAL

With the hose installed, remove the A/C compressor and clutch

assembly from the bracket.

NOTE: After removing the A/C compressor and clutch assem-

bly, secure it with a cord in the location where the removal and

installation of the engine assembly cannot be hindered.

.

<<D>> ATF WARMER (TRANSMISSION FLUID COOLER)

AND BRACKET ASSEMBLY REMOVAL

With the hose installed, remove the ATF warmer (transmission

fluid cooler) &bracket assembly from the transmission case

front roll stopper bracket.

.

AC301703

AC301704AB

AUTO-TENSIONER

HOLE B

HOLE A

AC301705AB

AUTO-TENSIONER

L-SHAPED

HEXAGON

WRENCH