Mitsubishi Galant (2004+). Manual - part 38

BODY REPAIR

TSB Revision

BASE OF BODY REPAIR

9-31

NOTES REGARDING REPAIR WORK

M4090015000028

SAFETY MEASURES

.

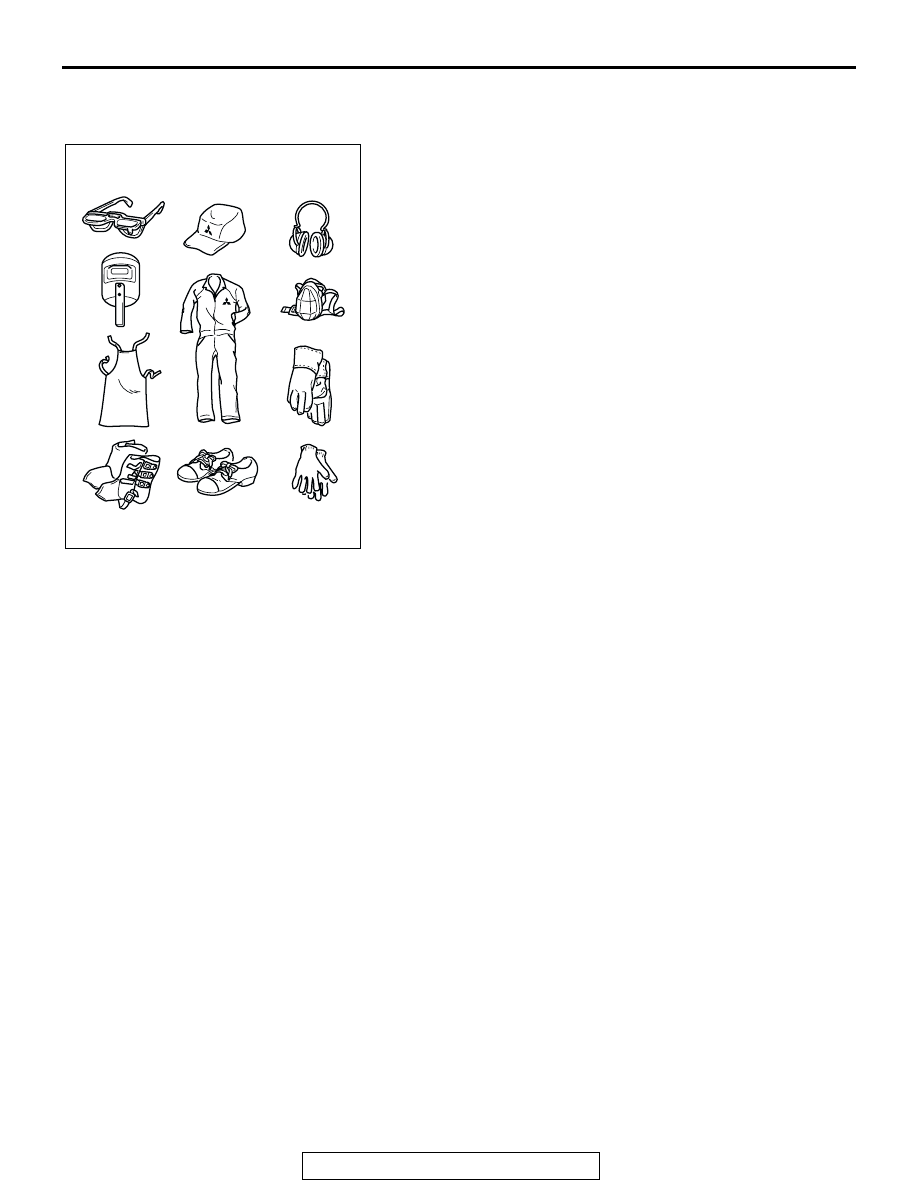

PROTECTIVE GEAR

During body repair work, a work suit, a work cap, and safety

shoes should be worn at all times. Depending on the work

being done, safety glasses, gloves, ear protectors, a dustproof

mask, etc., should also be worn as needed.

1. Safety glasses

2. Work cap

3. Ear protectors

4. Head protector

5. Work suit

6. Dustproof mask

7. Work apron

8. Welding gloves

9. Foot and ankle protectors

10. Safety shoes

11. Work gloves

.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

1. Items to review when servicing SRS

(1) Be sure to read Service Manual GROUP 52B,

Supplemental Restraint System (SRS). For

safe operation, please follow the directions

and heed all warnings.

(2) Wait at least 60 seconds after disconnecting

the battery cable before doing any further

work. The SRS system is designed to retain

enough voltage to deploy the air bag even

after the battery has been disconnected.

Serious injury may result from unintended air

bag deployment if work is done on the SRS

system immediately after the battery cable is

disconnected.

(3) Warning labels must be heeded when

servicing or handling SRS components.

(4) Always use the designated special tools and

test equipment.

(5) Store components removed from the SRS in a

clean and dry place. The air bag module

should be stored on a flat surface and placed

so that the pad surface is facing upward.

(6) Never attempt to disassemble or repair the

SRS components (SRS-ECU, air bag module

and clock spring). If there is a defect, replace

the defective part.

(7) Whenever you finish servicing the SRS, check

the SRS warning light operation to make sure

that the system functions properly.

(8) Be sure to deploy the air bag before disposing

of the air bag module or disposing of a vehicle

equipped with an air bag.

2. Observe the following when carrying out

operations on places where SRS components are

installed, including operations not directly related

to the SRS air bag.

(1) When removing or installing parts, do not allow

any impact or shock to occur to the SRS

components.

(2) If heat damage may occur during paint work,

remove the SRS-ECU, the air bag module,

clock spring, the front impact sensor, the side

impact sensor, and the seat belt pre-tensioner.

•

SRS-ECU, air bag module, clock spring, front

impact sensor, the side impact sensor: 93

°

C

(200

°

F) or more

•

Seat belt pre-tensioner: 90

°

C (194

°

F) or more

.

AB200104

1

4

5

6

7

8

9

10

11

2

3