Mitsubishi Galant. Manual - part 515

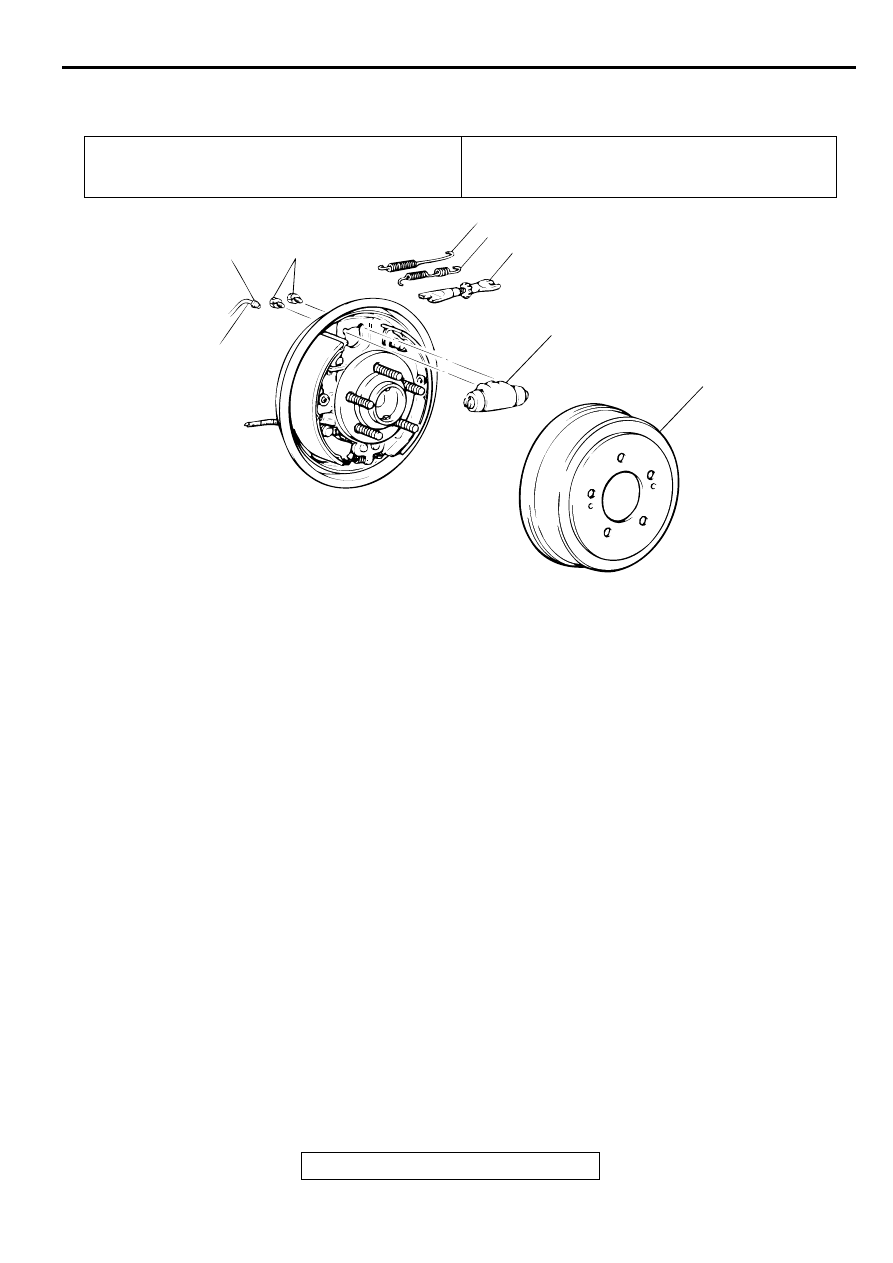

REAR DRUM BRAKE

TSB Revision

BASIC BRAKE SYSTEM

35A-51

REAR DRUM BRAKE WHEEL CYLINDER

M1351009300043

REMOVAL AND INSTALLATION

Pre-removal Operation

Brake Fluid Draining

Post-installation Operation

•

Brake Fluid Filling

•

Brake Line Bleeding (Refer to

.)

AC000927 AC

15 N·m

11 ft-lb

10 N·m

89 in-lb

5

3

2

4

6

1

REMOVAL STEPS

1. BRAKE DRUM

2. SHOE-TO-LEVER SPRING

3. SHOE-TO-SHOE SPRING

4. AUTO ADJUSTER ASSEMBLY

5. CONNECTION FOR THE BRAKE

PIPE

6. WHEEL CYLINDER

REMOVAL STEPS (Continued)