Mitsubishi Galant 9G. Manual - part 406

ON-VEHICLE SERVICE

TSB Revision

BASIC BRAKE SYSTEM

35A-16

PROPORTIONING VALVE FUNCTION TEST

<VEHICLES WITHOUT ABS>

M1351001100346

CAUTION

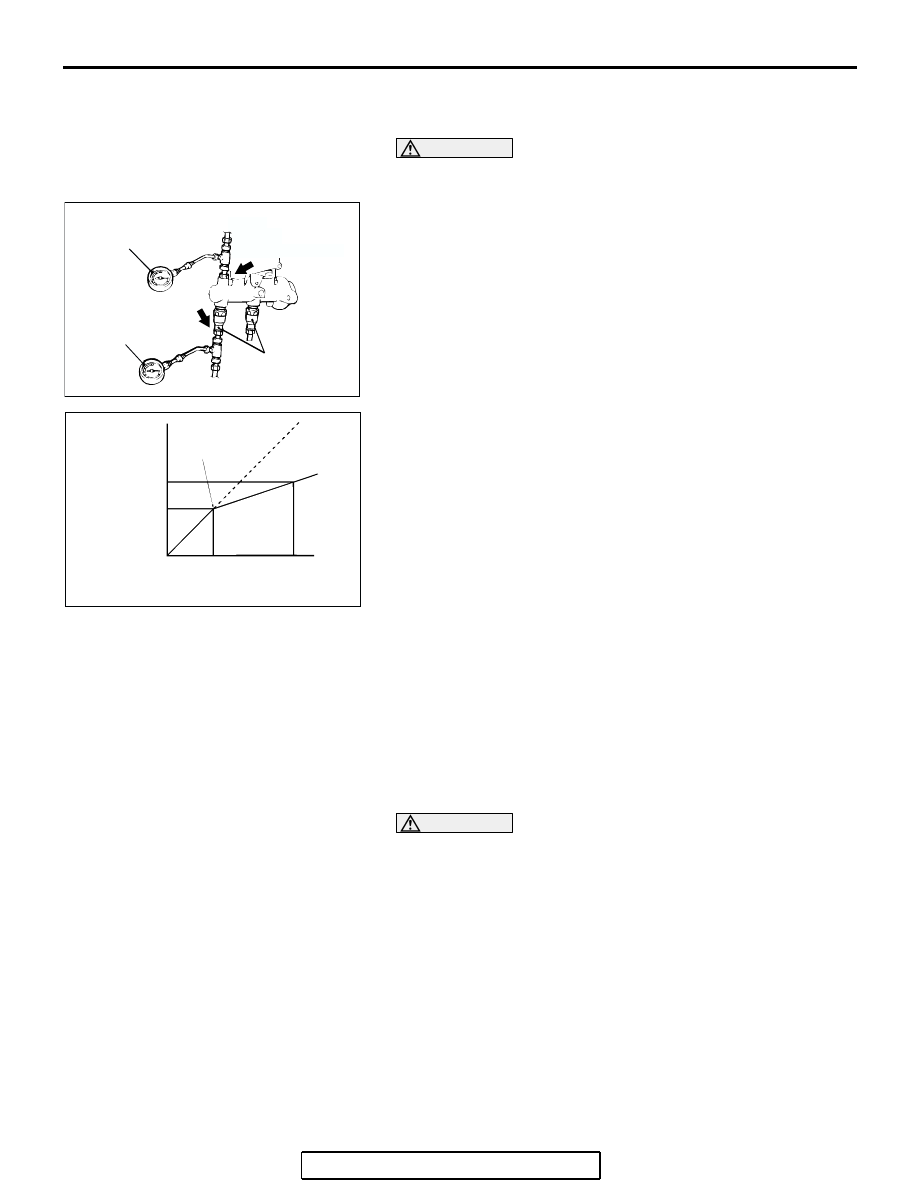

The proportioning valves are installed independently for

the right and left brake lines. Always measure each valve.

1. Connect two pressure gauges to the output port of the

master cylinder and output port of the proportioning valve.

2. Bleed the brake line and the pressure gauges (Refer to

3. Depress the brake pedal gradually. Then check that the split

point, where the output fluid pressure begins to drop in

proportion to the output fluid pressure, is at the standard

value.

Standard value: 3.68

− 4.17 MPa (534 − 605 psi)

4. Depress the brake pedal more strongly than at the above

step. Then check that the output fluid pressure is at the

standard value when the input fluid pressure is 7.85 MPa

(1,139 psi).

Standard value: 5.24

− 5.74 MPa (760 − 833 psi)

5. Measure each output fluid pressure at both valves, and

check that the difference between the two is at the limit

value or less.

Limit: 0.5 MPa (73 psi)

6. If the measured pressure exceeds the limit, replace the

proportioning valve.

BLEEDING

M1351001400455

CAUTION

Use only brake fluid DOT 3 or DOT 4. Never mix the speci-

fied brake fluid with other fluid as it will influence the brak-

ing performance significantly.

.

MASTER CYLINDER BLEEDING

The master cylinder used has no check valve, so if bleeding is

carried out by the following procedure, bleeding of air from the

brake pipeline will become easier. (When brake fluid is not con-

tained in the master cylinder).

1. Fill the reserve tank with brake fluid.

2. Keep the brake pedal depressed.

AC006221AD

PROPORTIONING

VALVE

OUTPUT PORT

PRESSURE GAUGE (A)

PRESSURE GAUGE (B)

OUTPUT PORT

AC006222 AB

SPLIT POINT

INPUT PRESSURE

<PRESSURE GAUGE (A)>

OUTPUT

PRESSURE

<PRESSURE

GAUGE (B)>