Mitsubishi Pajero Pinin. Manual - part 266

STEERING –

Power Steering Gear Box and Linkage

37A-25

Caution

Do not use Dia Queen ATF SP

II

and

ATF SP

II

M

as

they damage the components of the power steering.

2.

Apply the specified fluid to the oil seal inner surface and

the O-ring.

Specified fluid:

Automatic transmission fluid

DEXRON or DEXRON

II

Caution

Do not use Dia Queen ATF SP

II

and

ATF SP

II

M

as

they damage the components of the power steering.

3.

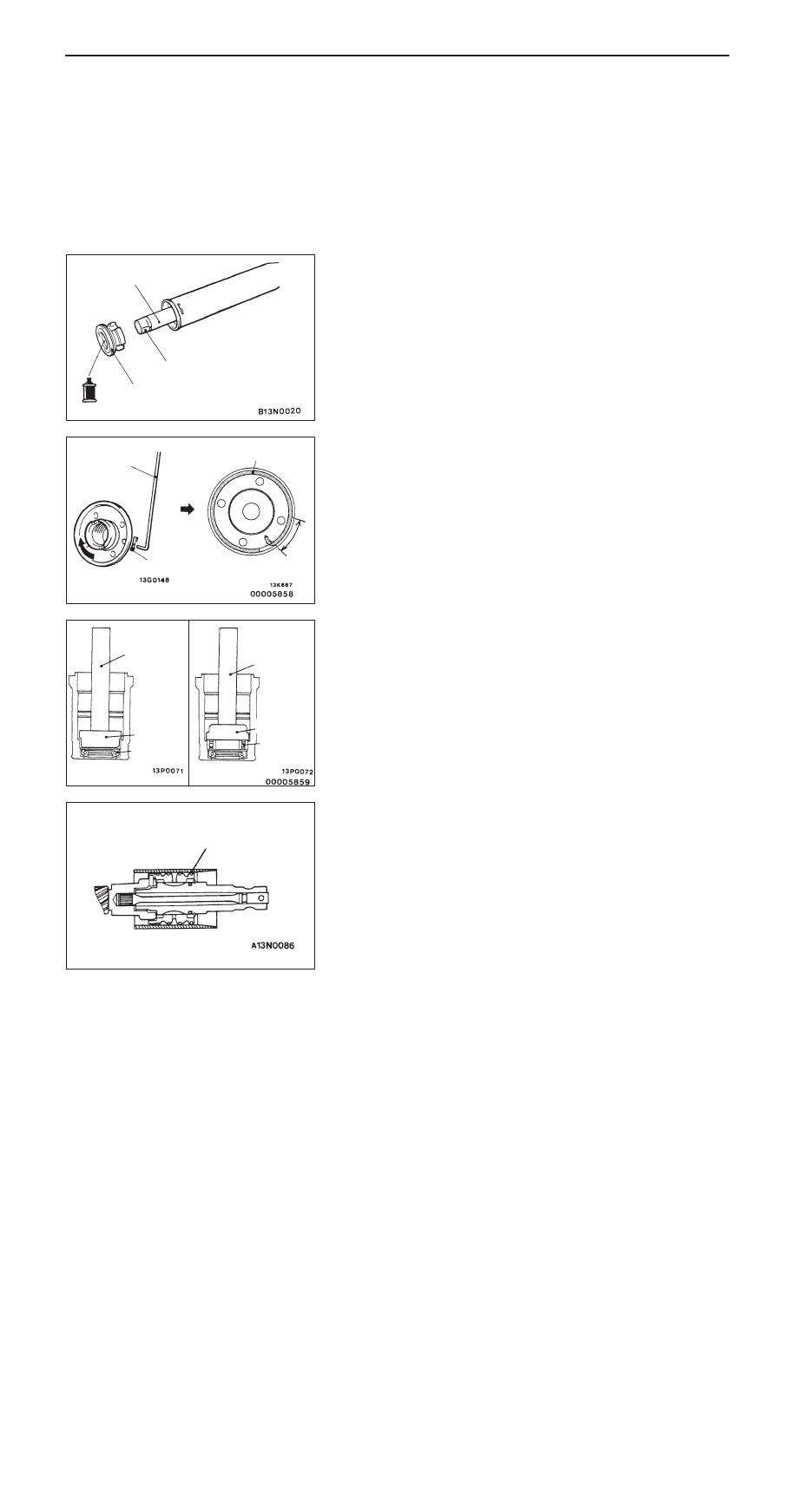

Wrap the rack end with plastic tape, and push the rack

bushing onto the rack.

"

E

A

CIRCLIP INSTALLATION

Align the mark on the rack stopper and the slot in the cylinder.

Then, insert the circlip into the rack stopper hole through the

cylinder hole. Turn the rack stopper clockwise and insert the

circlip firmly.

"

F

A

UPPER OIL SEAL/UPPER BEARING

INSTALLATION

"

G

A

SEAL RING INSTALLATION

After installation, using the special tool or by hand, compress

seal rings that expand during installation.

Rack bushing

Plastic tape

Rack

Circlip

Slot

Circlip

Slot

Upper oil

seal

MB990925

(MB990938)

MB990925

(MB990938)

MB991203

MB991203

Bearing

MB991317