Mitsubishi Pajero Pinin. Manual - part 211

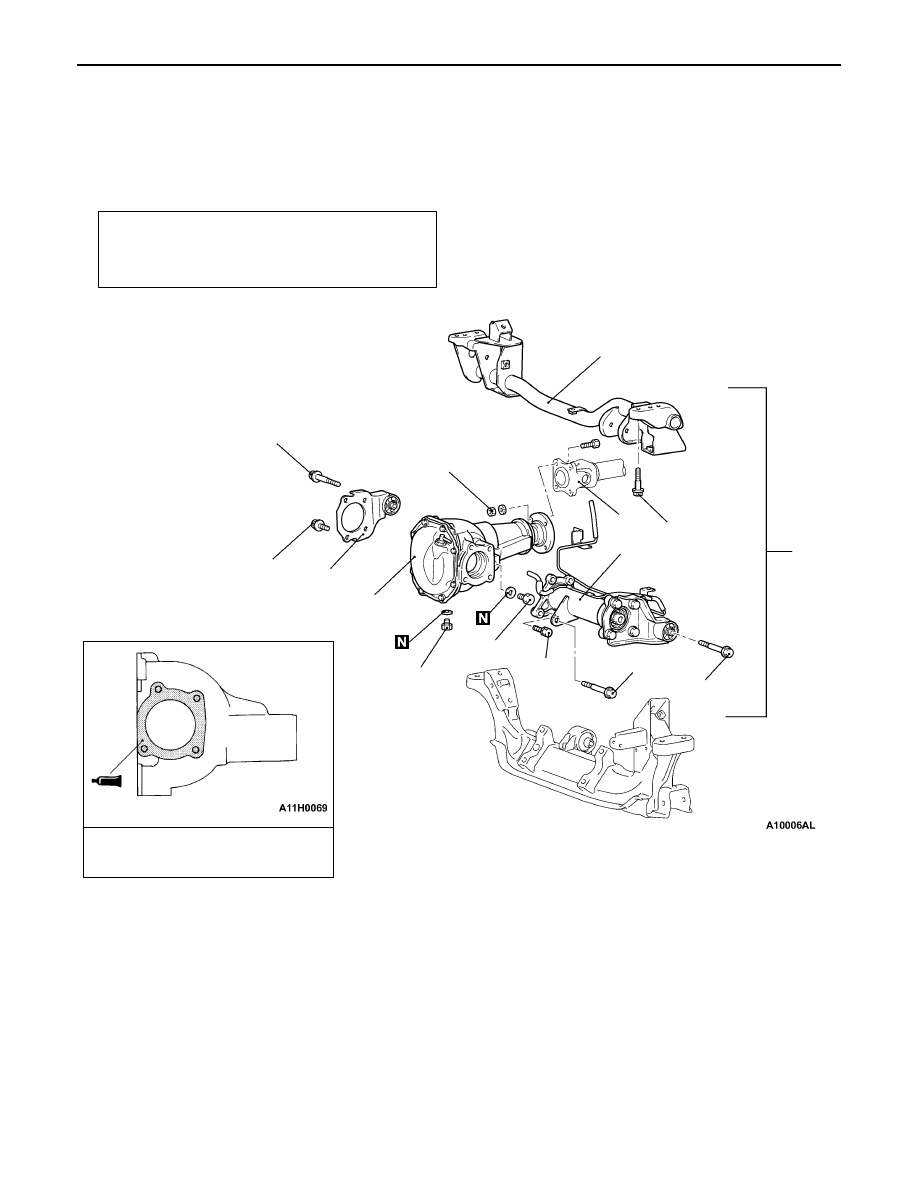

FRONT AXLE –

Differential Carrier

26-9

DIFFERENTIAL CARRIER

REMOVAL AND INSTALLATION

Caution

To prevent bushings from breakage, the parts indicated by * should be temporarily tightened, and then fully

tightened with the vehicle on the ground in the unladen condition.

Pre-removal and Post-installation Operation

D

Drive Shaft Removal and Installation

D

Stabilizer Bar Removal and Installation

D

Gear Oil Draining and Refilling

Sealant:

3M ATD Part No.8661 or

equivalent

4

5

2

6

1

3

93

±

15 N·m*

88

±

5 N·m

54

±

4 N·m

103

±

15 N·m

93

±

15 N·m*

108

±

10 N·m*

88

±

10

N·m

49

±

9 N·m

64

±

4 N·m

Removal steps

A

A

"

D

Support the Engine Assembly

1. Front propeller shaft connection

2. Front differential assembly and

differential mount crossmember

assembly

3. Front axle assembly

4. Differential mount bracket assembly

<RH>

5. Differential carrier

6. Differential mount crossmember

assembly

NOTE

Removal service points are the same as before.