Mitsubishi Pajero Pinin. Manual - part 143

ENGINE ELECTRICAL –

Charging System

16-2

CHARGING SYSTEM

GENERAL INFORMATION

The charging system uses the alternator output to

keep the battery charged at a constant level under

various electrical loads.

OPERATION

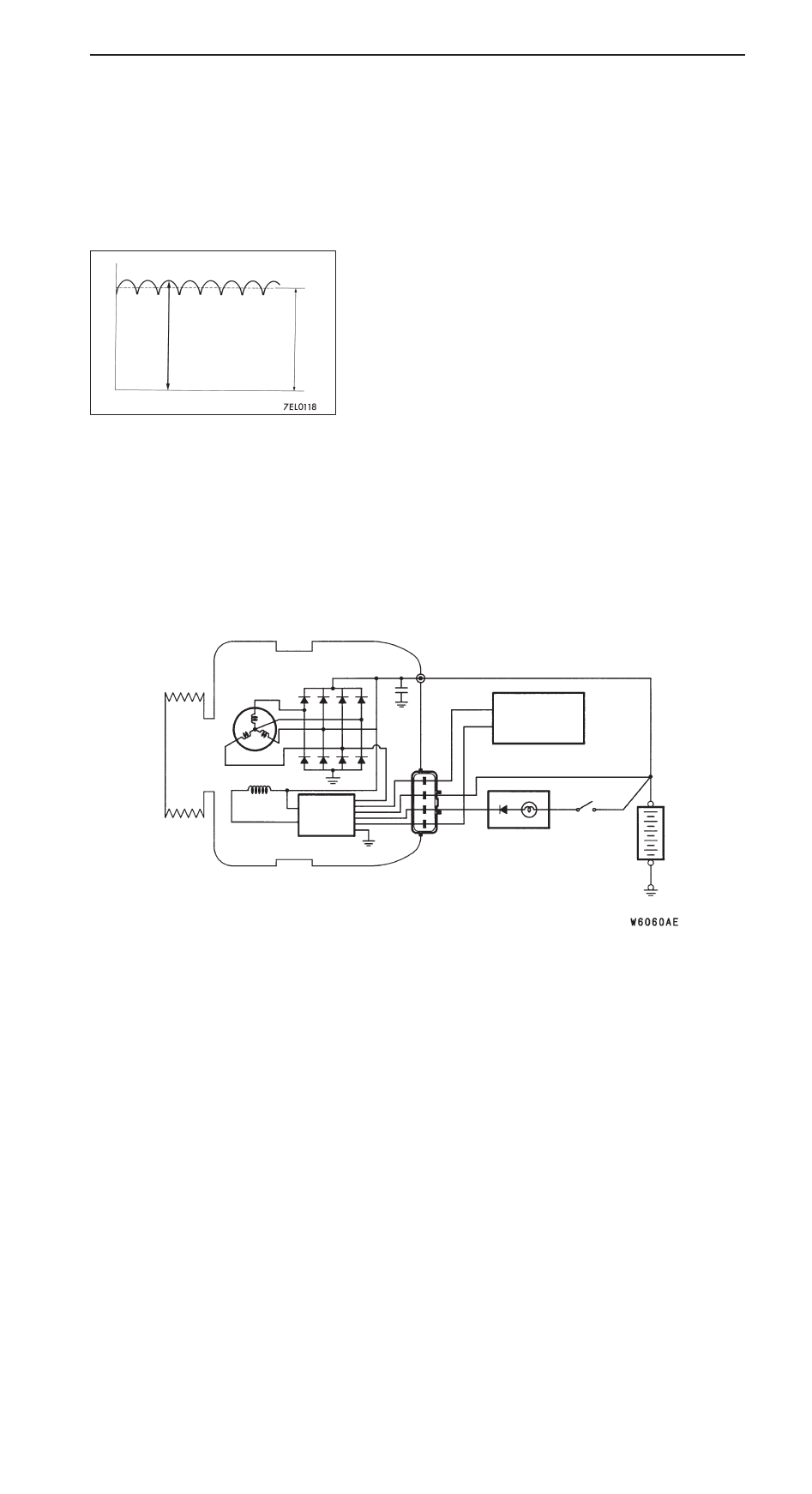

Rotation of the excited field coil generates AC voltage in the

stator.

This alternating current is rectified through diodes to DC voltage

having a waveform shown in the illustration at left. The average

output voltage fluctuates slightly with the alternator load

condition.

When the ignition switch is turned on, current flows

in the field coil and initial excitation of the field coil

occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by

the output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When the battery voltage (alternator S

terminal voltage) reaches a regulated voltage of

approx. 14.4 V, the field current is cut off. When

the battery voltage drops below the regulated

voltage, the voltage regulator regulates the output

voltage to a constant level by controlling the field

current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

SYSTEM DIAGRAM

Stator coil

Field coil

Voltage

regulator

Engine-ECU

Charging

warning lamp

Ignition

switch

Battery

B

G

L

FR

S

+

–

Voltage

Time

Approx. 14.4 V