Mitsubishi Pajero Pinin. Manual - part 141

INTAKE AND EXHAUST –

General/Service Specification/Air Cleaner

15-1

GROUP 15

INTAKE AND EXHAUST

GENERAL

OUTLINE OF CHANGES

The following service procedures have been established due to the addition of vehicle with 4G9-MPI engine.

Other contents are the same as 4G9-GDI engine.

SERVICE SPECIFICATION

Items

Standard value

Limit

Distortion of the intake manifold installation surface mm

0.15 or less

0.20

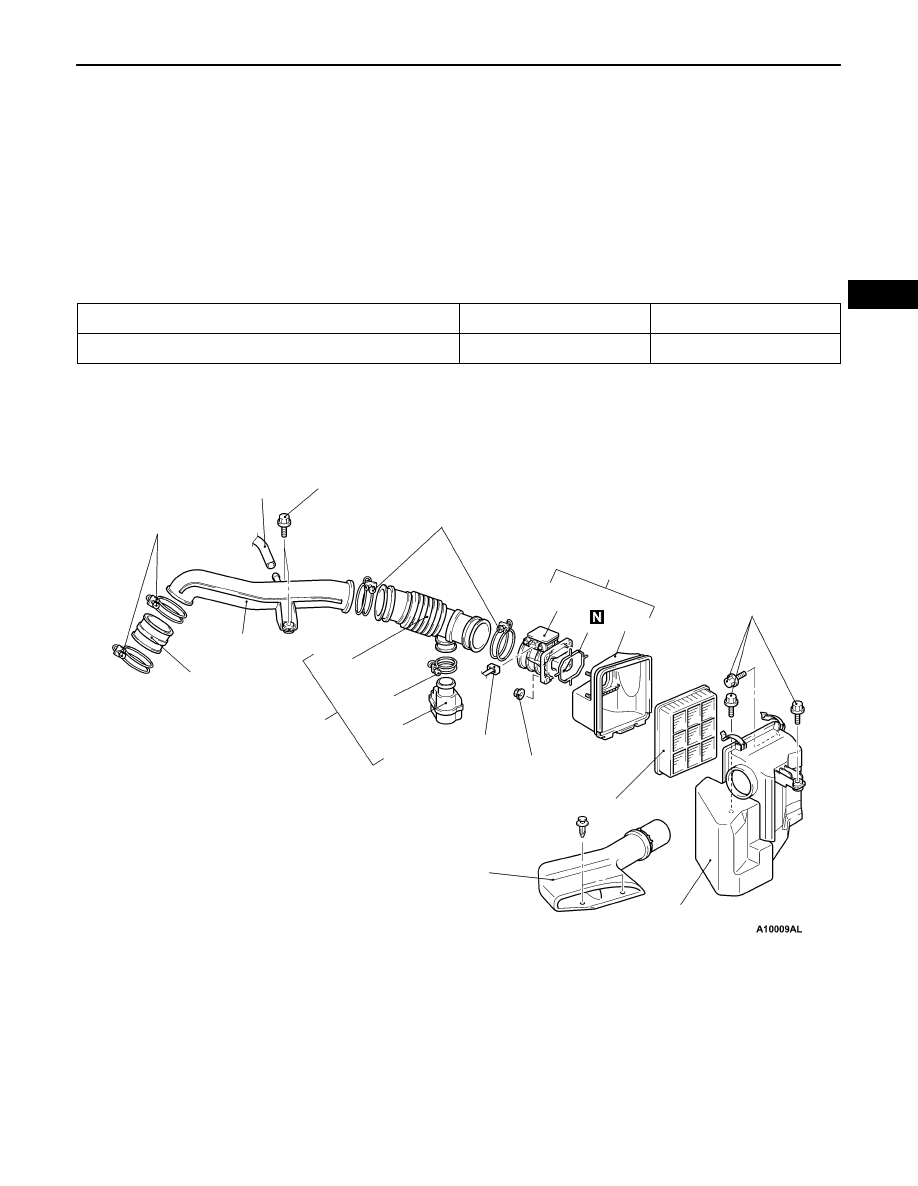

AIR CLEANER

REMOVAL AND INSTALLATION

<4G9-MPI>

1

3

4

5

6

7

9

2

8

10

4.0

±

1.0

N

·

m

12

±

2

N

·

m

3.9

±

1.0

N

·

m

9.0

±

1.0

N

·

m

8.8

±

1.0

N

·

m

3.9

±

1.0

N

·

m

11

12

13

Removal steps

1. Air intake hose and resonator

2. Air intake hose

3. Resonator

4. Air flow sensor connector

5. Air flow sensor and air cleaner cover

6. Air flow sensor

7. Air cleaner cover

8. Air cleaner element

9. Air duct

10. Air cleaner

11. Breather hose connection

12. Air intake pipe

13. Air hose