Mitsubishi Pajero Pinin. Manual - part 61

GDI –

Fuel Pump (High Pressure) and Fuel Pressure Regulator (High Pressure)

13A-110

"

C

A

FUEL RETURN PIPE/FUEL PRESSURE

HOSE/FUEL FEED PIPE INSTALLATION

Apply a small amount of fresh engine oil to the O-ring.

Caution

Take care not to let any of the engine oil get inside the

fuel pump (high pressure), fuel pressure regulator (high

pressure) or the delivery pipe assembly.

"

D

A

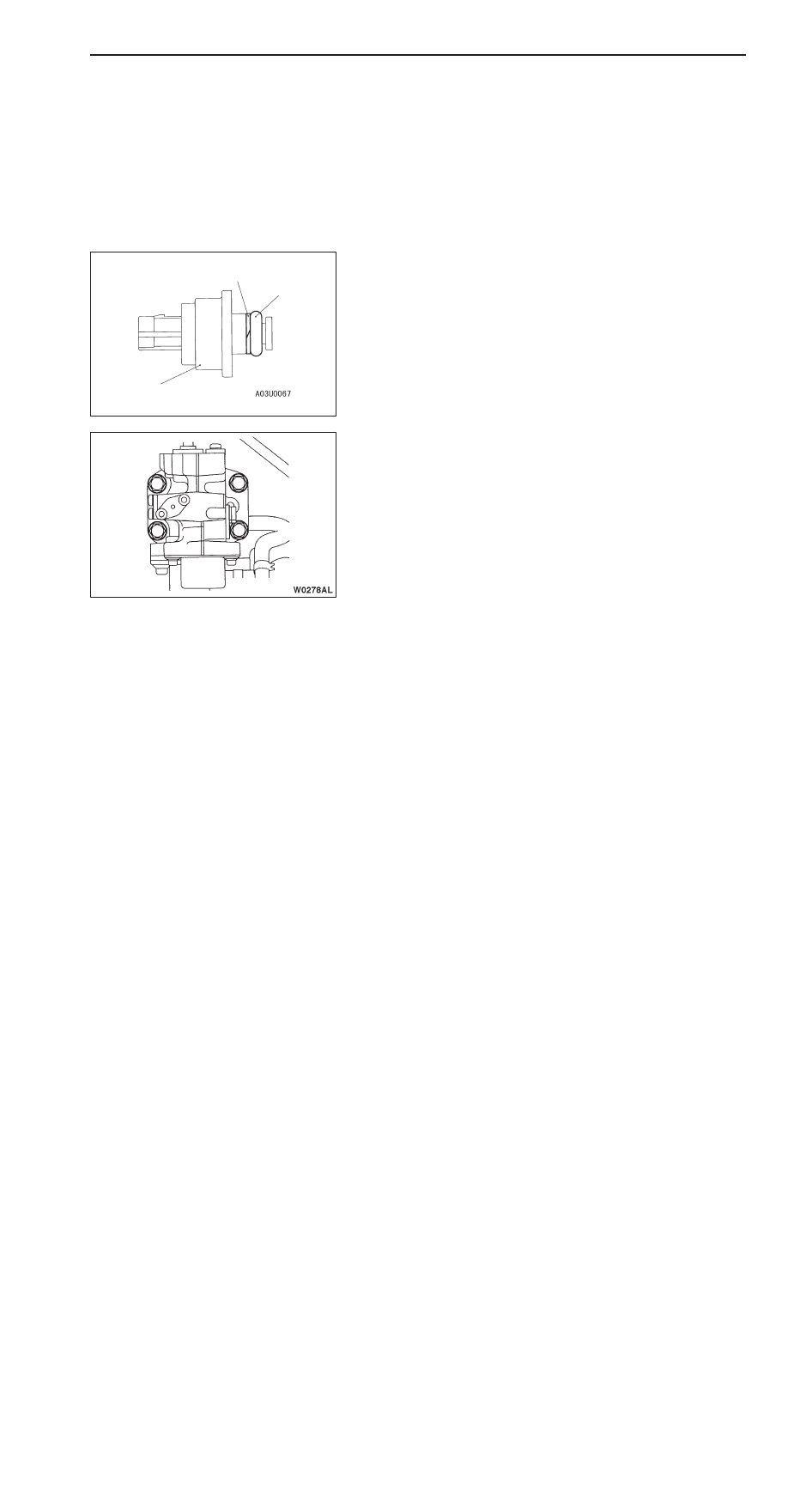

BACK-UP RING/O-RING INSTALLATION

Install the back-up ring and the O-ring as shown in the

illustration.

Caution

Take care not to install the back-up ring A for the injector,

fuel feed pipe or fuel return pipe by mistake. (Outer

diameter of the back-up ring for the fuel pressure sensor:

15.1 mm)

"

E

A

FUEL PUMP (HIGH PRESSURE) INSTALLATION

1.

Apply a small amount of fresh engine oil to the fuel pump

(high pressure) roller and O-ring.

2.

Install temporarily the fuel pump (high pressure) to the

cylinder head.

3.

Install the fuel feed pipe, and then tighten the fuel pump

(high pressure) mounting bolts to 5 Nm in the order shown

in the illustration.

4.

Tighten the bolts to 17 Nm in the order shown in the

illustration. The overall difference in tightening torque

between the four bolts should be within 2 Nm.

"

F

A

FUEL PUMP (HIGH PRESSURE) AIR BLEEDING

1.

Run the engine at 2,000 r/min for 15 seconds or more

in order to bleed the air.

NOTE

When removing the fuel pump (high pressure), air may

get into the fuel pump (high pressure). If air gets into

the fuel pump (high pressure), diagnosis code No.56 for

abnormal fuel pressure will be output.

2.

Use the MUT-

II

to check the diagnosis code. If the

diagnosis code No.56 for fuel pressure sensor system

defect is output, erase it.

Back-up ring

O-ring

Fuel pressure sensor

1

2

3

4