Mitsubishi Pajero Pinin. Manual - part 5

GENERAL –

Support Locations for Lifting and Jacking

00-27

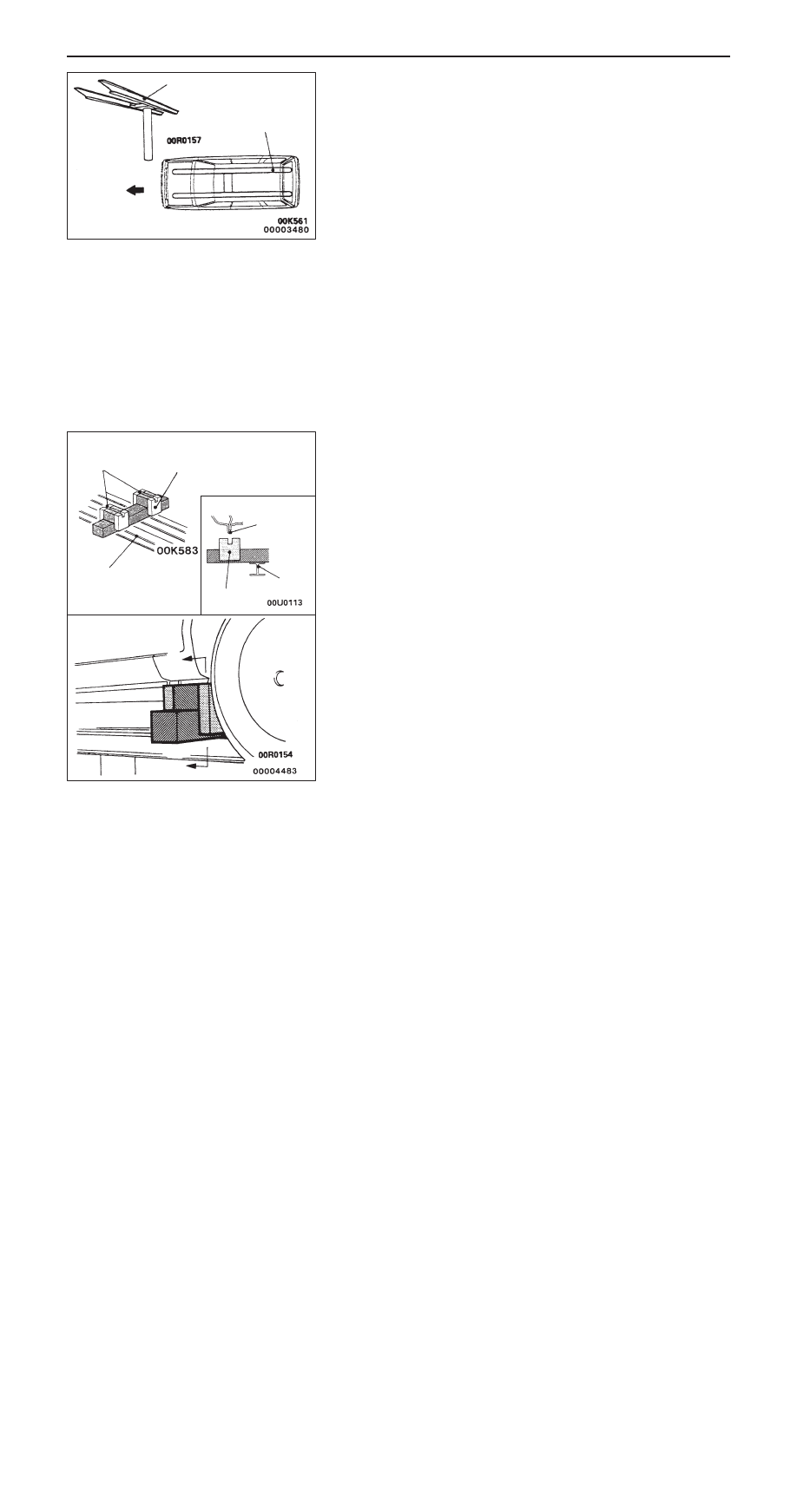

SUPPORT POSITIONS AND SUPPORT METHOD

FOR AN H-BAR LIFT

Caution

When service procedures require removing the rear

suspension, fuel tank, spare tyre and rear bumper, place

additional weight on rear end of vehicle or anchor vehicle

to hoist to prevent tipping of centre of gravity changes.

When H-bar lift is used to lift up vehicles, use of metallic

attachment attached to the H-bar lift may cause damage to

the suspension arm etc. Therefore, lift up the vehicle by the

following procedure.

1.

Place the vehicle on the H-bar lift (same direction).

2.

Place attachments on the H-bar lift at the designated

chassis-support positions. When making the attachments,

refer to the section concerning making them.

Caution

If support is at any location other than the designated

positions, the body or suspension might be deformed

or otherwise damaged, so care should be taken to

support only at the correct (designated) positions.

3.

Raise the H-bar lift to the height at which the vehicle is

slightly raised and check to be sure that the vehicle is

correctly and sufficiently secured; then raise the vehicle.

H-bar lift

H-bar lift

A

Chassis-sup-

port position

(side sill)

Attachment

H-bar lift

Section A–A

Side sill

Attachment

H-bar lift

A