Mitsubishi Pajero Pinin. Manual - part 2

GENERAL –

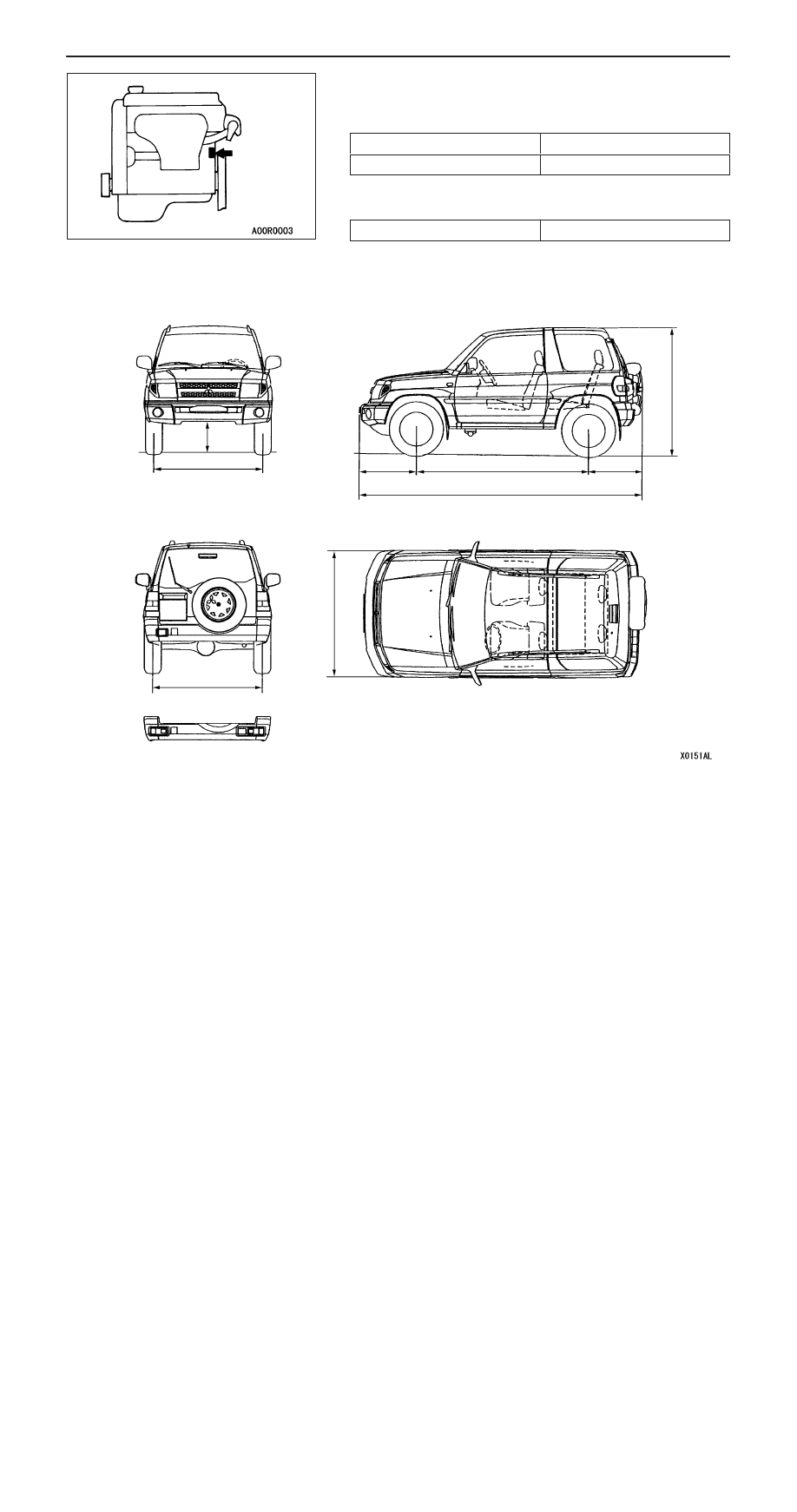

Vehicle Identification/Major Specifications

00-15

ENGINE MODEL NUMBER

1.

The engine model number is stamped on the cylinder

block as shown below.

Engine model

Engine displacement m

ȏ

4G93

1,834

2.

The engine serial number is stamped near the engine

model number.

Engine serial number

AA0201 to YY9999

MAJOR SPECIFICATIONS

2

5

7

9

4

1

8

6

3

<R.H. drive

vehicles>

<L.H. drive

vehicles>