Mitsubishi Lancer. Manual - part 230

TRUNK LID

BODY

42-42

3. If there is a difference in height between the side

outer panels and the side edges of the trunk lid

panel assembly, check the trunk lid hinges and, if

necessary, replace them

4. If the clearance around the trunk lid panel

assembly is not uniform, and the trunk lid can be

locked and unlocked smoothly, make adjustments

to the trunk lid bumpers (refer to

5. If the locking and unlocking of the trunk lid still is

difficult after making the above adjustments,

adjust the trunk lid striker (Refer to

).

ADJUSTMENT OF CLEARANCE AROUND

TRUNK LID

M1421008100039

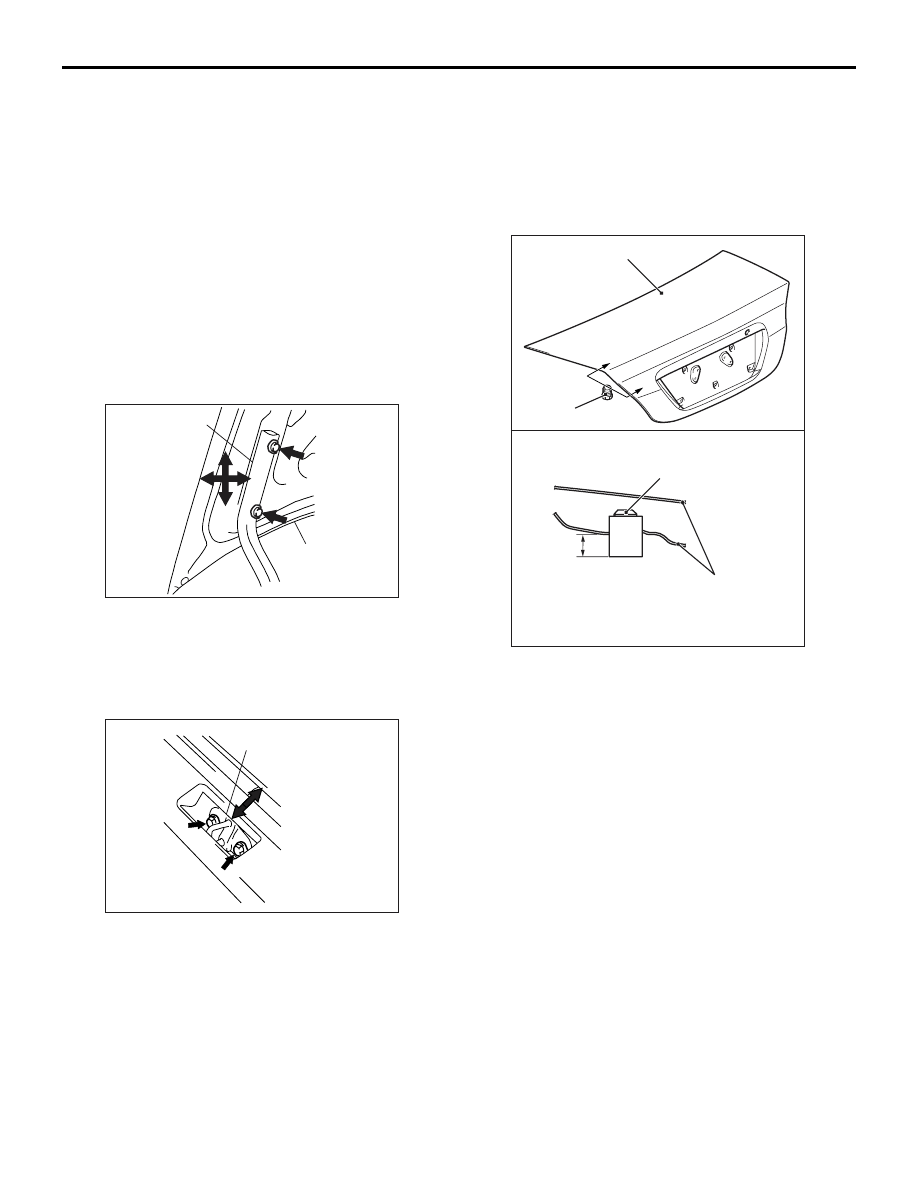

AC202897

Trunk lid panel

assembly

Trunk lid hinge

AB

Loosen the trunk lid panel assembly mounting bolts

and move the trunk lid panel assembly to make the

clearance around the trunk lid uniform.

TRUNK LID STRIKER ADJUSTMENT

M1421008200036

AC202898

Trunk lid striker

AB

After checking the trunk lid release cable for proper

routing, loosen the trunk lid striker mounting bolts.

Change the position of the trunk lid striker relative to

the trunk lid latch assembly so that trunk lid locking

and unlocking effort is correct.

TRUNK LID HEIGHT ADJUSTMENT

M1421008300033

AC305144

Section A - A

Trunk lid bumper

Trunk lid panel assembly

A

A

Trunk lid bumper

Trunk lid panel assembly

AB

14 mm

Turn each trunk lid bumper until the height shown in

the drawing is reached. If the trunk lid panel height

on one side is different from that on the other side

(even after the trunk lid bumpers have been adjusted

to the height indicated in the drawing), turn the trunk

lid bumper(s) slightly to make fine adjustments to the

trunk lid panel height.

NOTE: When the bumper is new, one full turn of the

trunk lid bumper changes the height approximately 3

mm. Turn it clockwise to reduce height. Turn it anti-

clockwise to increase height.