Mitsubishi Lancer. Manual - part 219

ON-VEHICLE SERVICE

ENGINE LUBRICATION

12-4

ON-VEHICLE SERVICE

ENGINE OIL CHECK

M1121000900342

ACX00892 AC

Good

Maximum

Minimum

<4G1>

AC205268

Maximum

Minimum

Good

AC

<4G6>

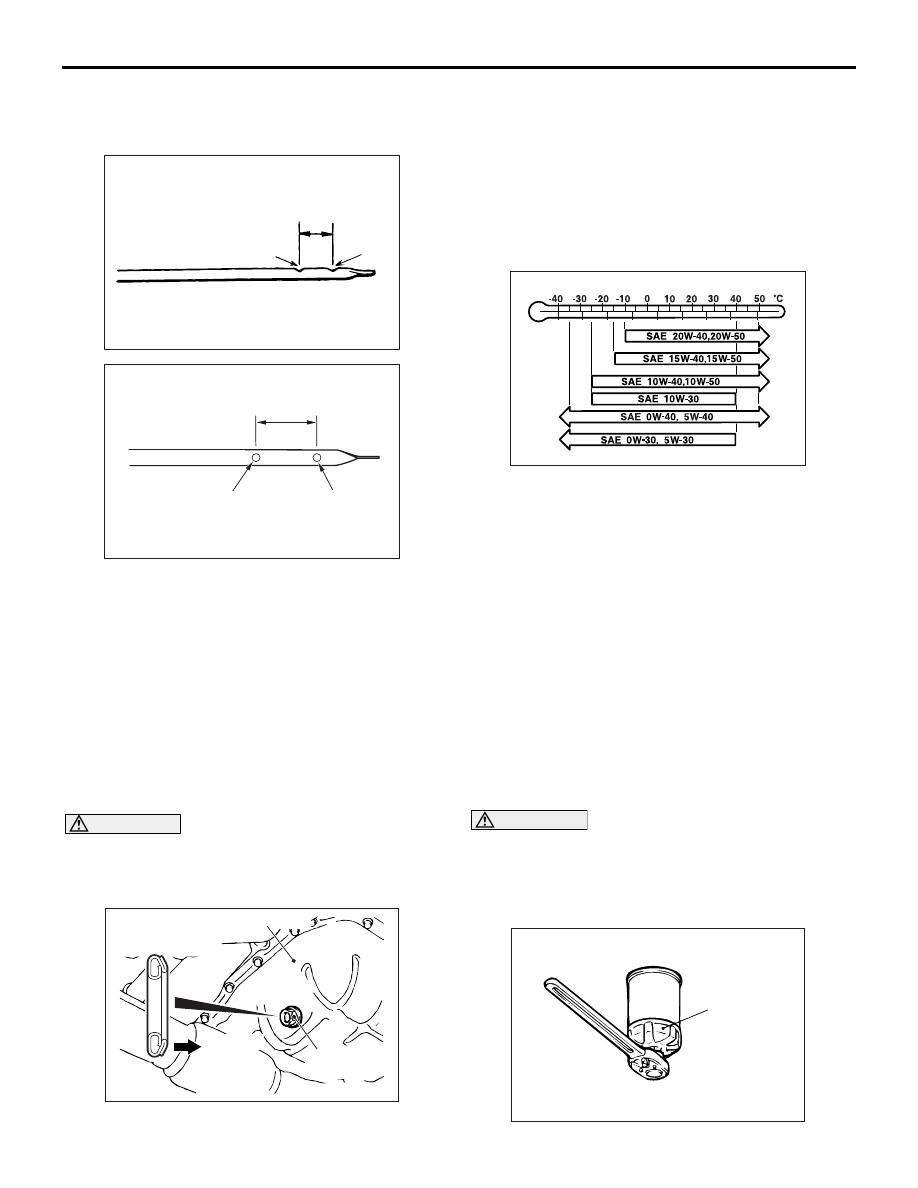

1. Pull out the engine oil level gauge slowly and

check that the oil level is in the illustrated range.

2. Check that the oil is not excessively dirty, that

there is no coolant or petrol mixed in, and that it

has sufficient viscosity.

ENGINE OIL REPLACEMENT

M1121001000416

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80

° C to 90

° C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

AC208299

Engine oil pan

AC

Engine oip pan

drain plug

Engine oip pan

drain plug

Engine oil

pan side

4. Install a new engine oil pan drain plug gasket so

that it faces in the direction shown in the

illustration, and then tighten the engine oil pan

drain plug to the specified torque.

Tightening torque: 39

± 5 N⋅ m

NOTE: Install the engine oil pan drain plug gasket

so it faces in the direction shown in the illustration.

AC301513

5. Refill with specified quantity of engine oil.

Specified Engine Oil (ACEA and API classifica-

tion): ACEA A1, A2 or A3/API SG or higher

Total quantity (Includes volume inside engine

oil filter):

3.3 L <4G1>

4.3 L <4G6>

6. Install the engine oil filler cap.

7. Check engine oil level.

ENGINE OIL FILTER REPLACEMENT

M1121001100383

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80

° C to 90

° C.

2. Remove the engine oil filler cap.

CAUTION

Use care as engine oil could be hot.

3. Remove the engine oil pan drain plug to drain

engine oil.

4. Remove the under cover.

AC000093

MB991396

<4G1>,

MB991828

<4G1>,

MB991610

<4G6> or

commercially-

available tool

AI