Mitsubishi Lancer. Manual - part 71

OPERATIONS INSIDE THE VEHICLE

PERIODIC INSPECTION AND MAINTENANCE

2-20

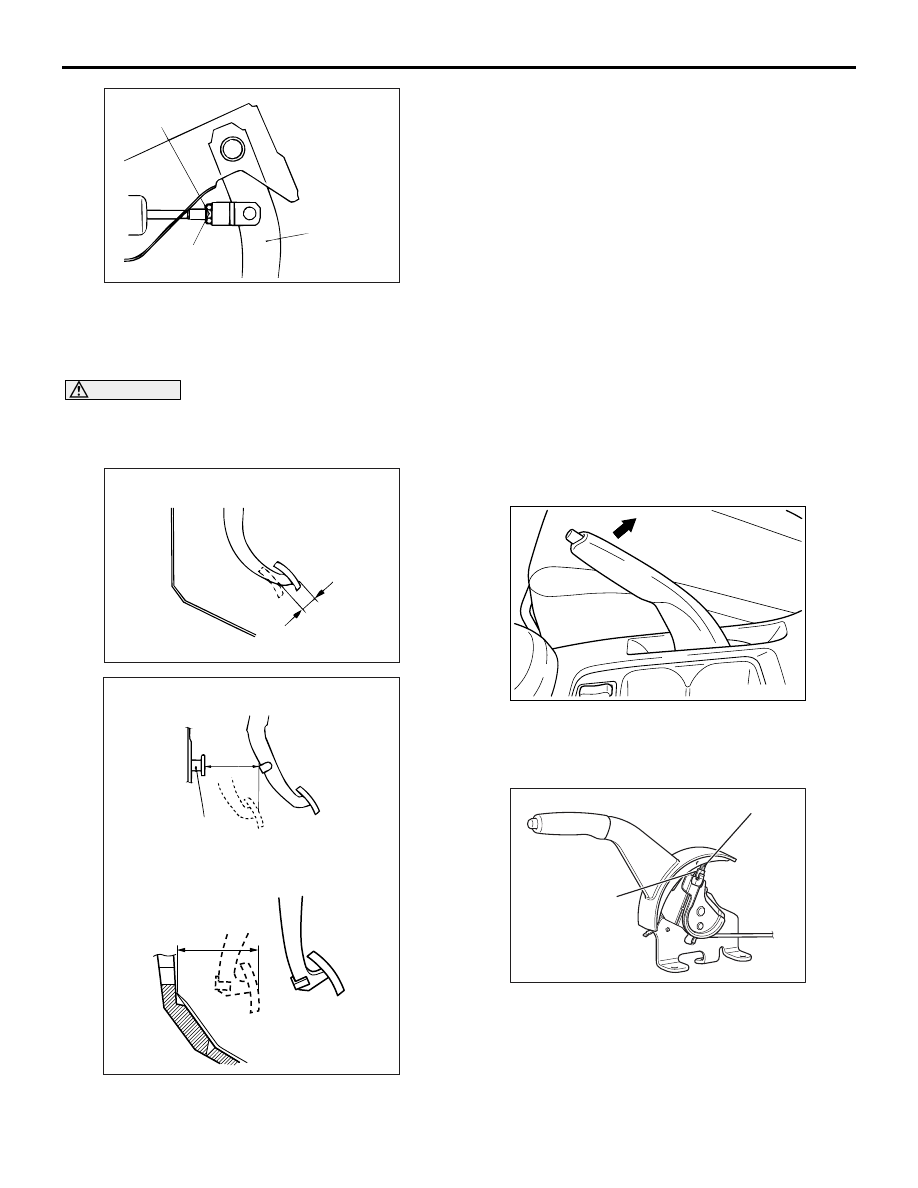

4. If the clutch pedal height and clutch pedal clevis

pin play are not within the standard value, loosen

the setting nut to adjust the clutch pedal height

and clevis pin play to the standard value.

CAUTION

Do not push in the master cylinder pushrod at

this time, otherwise the clutch will not operate

properly.

5. After completing the adjustments, confirm that the

clutch pedal free play (measured at the face of the

pedal pad) and the distance between the clutch

pedal (the face of the pedal pad) and the clutch

pedal stopper or dash pad when the clutch is

disengaged are within the standard value ranges.

Standard value (C): 4

− 13 mm

Standard value (D): 105 mm or more

6. If the clutch pedal free play and the distance

between the clutch pedal and the clutch pedal

stopper or dash pad when the clutch is

disengaged do not agree with the standard

values, it is probably the result of either air in the

hydraulic system or a faulty master cylinder,

release cylinder or clutch. Bleed the air, or

disassemble and inspect the master cylinder,

release cylinder or clutch.

C2. CHECK PARKING BRAKE LEVER

STROKE AND PLAY

M6020400200119

1. Pull the parking brake lever with a force of approx.

200 N and count the number of notches.

Standard value: 5

− 7 notches

2. If the parking brake lever stroke is not the

standard value, adjust as described below.

(1) Remove the floor console assembly.

(2) Loosen the adjusting nut to move it to the

cable rod end so that the cable will be free.

AC100356

Setting nut

Clutch pedal

13 ± 2 N·m

AB

AC100355 AC

C

Clutch pedal free play

AC310575

<LH drive vehicles>

Clutch pedal

stopper

D

AB

<RH drive vehicles>

D

AC303998

AB

AC107239

Cable rod

Adjusting nut

AD