Mitsubishi Lancer. Manual - part 72

OPERATIONS OUTSIDE THE VEHICLE

PERIODIC INSPECTION AND MAINTENANCE

2-24

2. Carry out adjustment by turning the camber

adjusting bolt (lower arm assembly mounting bolt

which is located on the inner side of the body).

Left wheel: Turning clockwise (+) camber

Right wheel: Turning clockwise (

−) camber

NOTE:

The scale has gradations of approximately 14’.

3. Tighten the control link to the trailing arm.

CAUTION

To prevent bushings from breakage, the connect-

ing bolt should be temporarily tightened, and

then fully tightened to 90

± 10 N⋅m with the vehi-

cle on the ground in the unladen condition.

4. After adjusting the camber, the toe should be

adjusted.

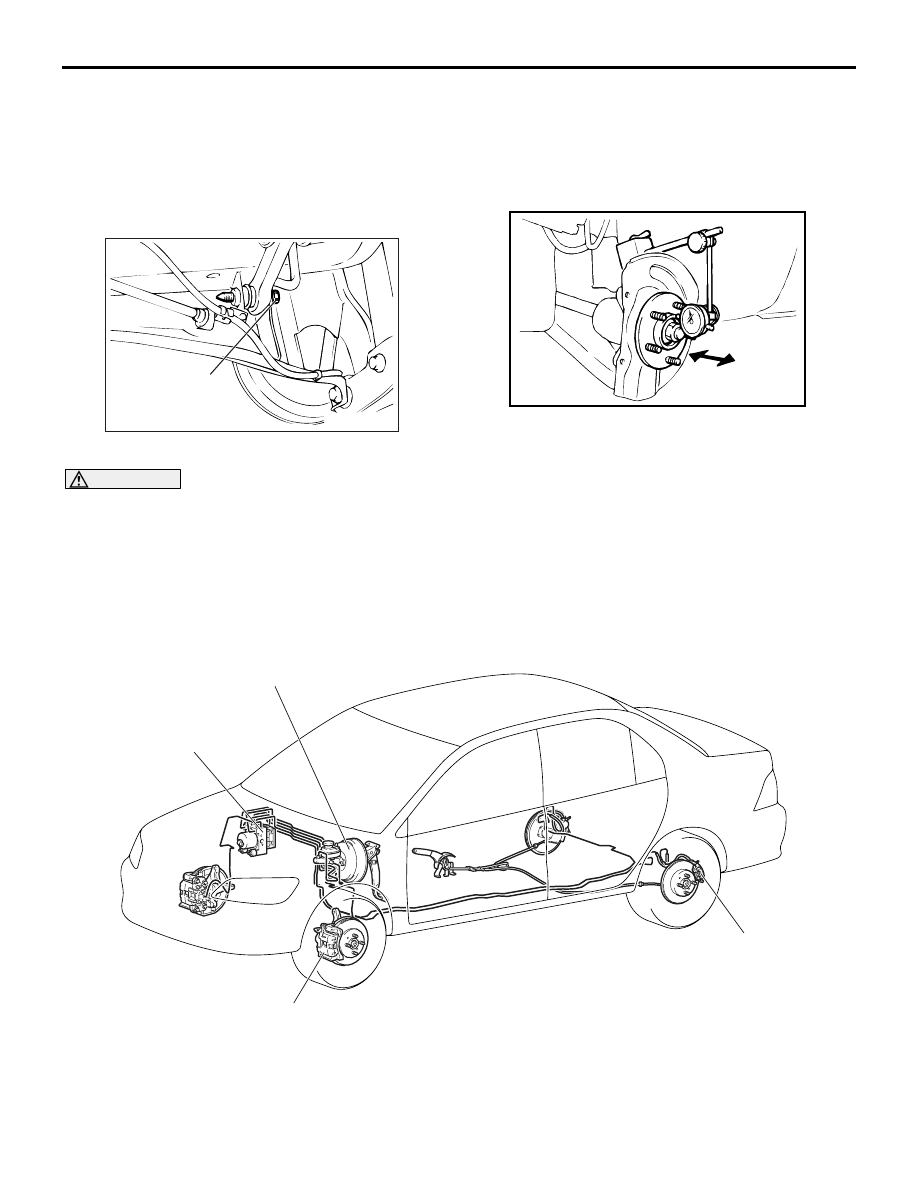

D2. CHECK FRONT WHEEL BEARINGS

FOR PLAY

M6020500200020

1. Remove the disc brake caliper and suspend it

with a wire.

2. Remove the brake disc from the front hub.

3. Attach a dial gauge as shown in the illustration,

and then measure the axial play while moving the

hub in the axial direction.

Limit: 0.05 mm

4. If axial play exceeds the limit, replace the front

hub assembly.

D3. CHECK BRAKE HOSES AND PIPES

FOR LEAKAGE

M6020500300072

1. Check entire circumference and length of hoses

and pipes.

2. Check all clamps for tightness and connections

for leakage.

AC006160 AC

Connecting bolt

AC102438AD

AC304027AC

Rear disc brake

Front disc brake

Brake booster assembly

Brake modulator

hydraulic unit