Mitsubishi Lancer. Manual - part 69

OPERATIONS INSIDE THE ENGINE COMPARTMENT

PERIODIC INSPECTION AND MAINTENANCE

2-12

4. When the engine coolant has drained, pour in

water from the radiator cap to clean the engine

coolant line.

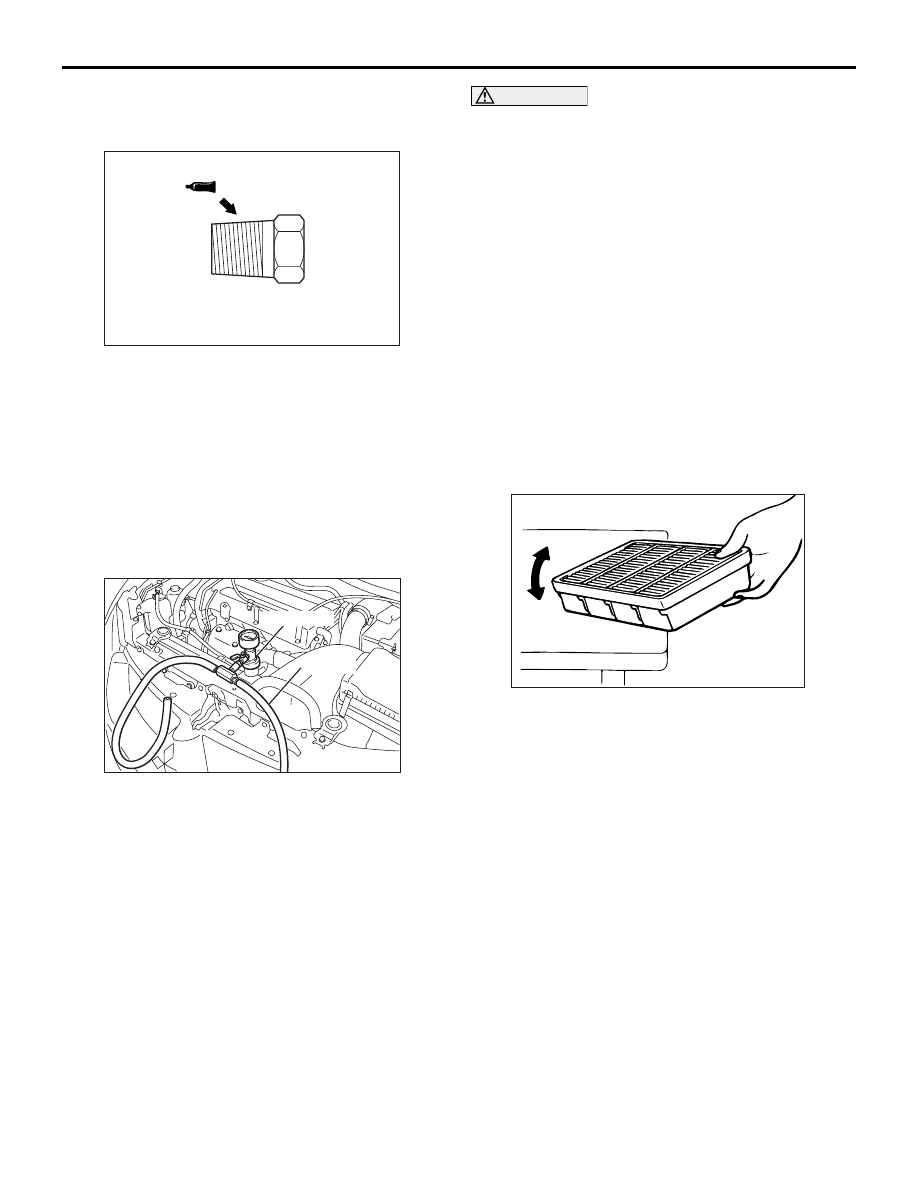

5. Coat the thread of the cylinder block drain plug

with the specified sealant and tighten to the

specified torque.

Specified sealant: 3M Nut Locking Part

No.4171 or equivalent

Tightening torque:

40

± 5 N⋅m <4G1>

44

± 5 N⋅m <4G6>

6. Securely tighten the radiator drain plug.

7. Install the reserve tank.

8. By referring to the section on coolant, select an

appropriate concentration for safe operating

temperature within the range of 30 to 60%. Use

special tool LLC changer (MB991871) to refill the

coolant. A convenient mixture is a 50% water and

50% antifreeze solution (freezing point:

−31°C)

NOTE: For How to use special tool MB991871,

refer to its manufacturer’s instructions.

Recommended antifreeze: DIA QUEEN

SUPER LONG LIFE COOLANT or equivalent

Quantity:

5.0L <4G1>

7.0L <4G6>

CAUTION

Do not use alcohol or methanol anti-freeze or any

engine coolants mixed with alcohol or methanol

anti-freeze. The use of an improper anti-freeze

can cause the corrosion of the aluminium com-

ponents.

9. Install the radiator cap securely.

10.Start the engine and warm the engine until the

thermostat opens. (Touch the radiator hose with

your hand to check that warm water is flowing.)

11.After the thermostat opens, race the engine

several times, and then stop the engine.

12.Cool down the engine, and then pour engine

coolant into the reserve tank until the level

reaches the FULL line. If the level is low, repeat

the operation from step 10.

A12. CHECK AIR CLEANER ELEMENT

FOR CLOGGING AND DAMAGE

M6020201200022

1. Check air cleaner element for clogging and

damage.

2. Clean deposited dust from the element in the

following manner.

(1) Lightly tap the element against the top of a

bench.

(2) Blow compressed air from inside the element.

3. Wipe off dust on the air cleaner interior.

4. Install the air cleaner body.

A13. REPLACE AIR CLEANER ELEMENT

M6020201300029

The air cleaner element will become dirty and loaded

with dust during use, and the filtering effect will be

substantially reduced. Replace it with a new one.

AC104528AE

AC210658AB

MB991871

Air hose

AC305657