Mitsubishi Lancer (4A9 engine). Manual - part 35

ACA00941

A

ACA00941AB

R7 ± 0.5 mm

5 ± 0.5 mm

Ø2 ± 0.5 mm

E-E

R8.5 ± 0.5 mm

Ø2 ± 0.5 mm

D-D

3 ± 0.5 mm

Ø2 ± 0.5 mm

F-F

R

R

H

R

R

15 mm

S-S

S

S

S

R-R

Ø2 ± 0.5 mm

G

C

C

C

C

G A

A

D

B

B

A

A

B

B

D

D

D

E

E

E

E

B

F

F

F

G

G

H

A

A

U

4.5 ± 0.5 mm

Ø1.75 ± 0.5 mm

C-C

3 ± 0.5 mm

Ø1.75 ± 0.5 mm

B-B

Ø1.75 ± 0.5 mm

A-A

Ø2 ± 0.5 mm

3 ± 0.5 mm

P

P

P

P

G

22 mm

6.1 mm

Ø2 ± 0.5 mm

Q

Q

P-P

Q-Q

U

V

V

V-V

W

S

W

W-W

6 mm

1 mm

1 mm

Ø1.75 ± 0.5 mm

A

B

TIMING CHAIN

ENGINE MECHANICAL <4A9>

11A-54

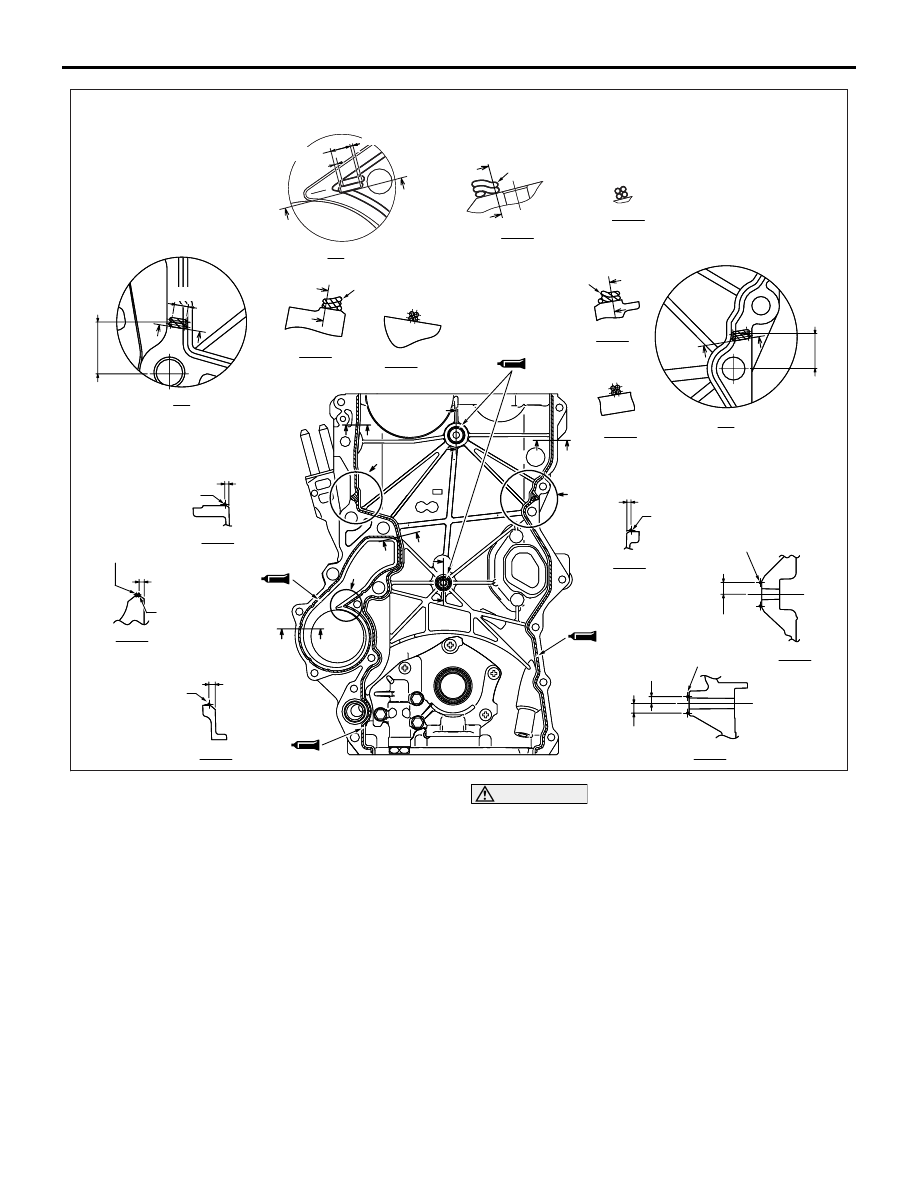

3. Apply a bead of the sealant to the cylinder block

and cylinder head mating surface of the timing

chain case assembly as shown.

Specified sealant:

A: ThreBond 1217G or equivalent

B: ThreBond 1217D or equivalent

NOTE: Install the timing chain case assembly

immediately after applying sealant.

CAUTION

• If the sealant contacts any other part during

installation of the timing chain case assembly,

apply sealant again before installing the tim-

ing chain case assembly.

• After the installation, until a sufficient period

of time (one hour or more) elapses, do not

apply the engine oil or water to the sealant

application area or start the engine.

4. Taking care not to scrub the specified sealant

applied on the timing chain case assembly with

the cylinder block etc., install the timing chain

case assembly to the cylinder block.