Mitsubishi Lancer (4A9 engine). Manual - part 34

Removal steps

1.

Earth cable connection

<<

A

>>

•

A/C compressor and clutch

assembly.

<<

B

>>

•

Engine and transmission assembly

supporting

•

Engine mounting bracket (Refer to

GROUP 32

− Engine Mounting )

2.

Alternator brace

>>

E

3.

Crankshaft front oil seal

>>

D

<<

4.

Water pump assembly

>>

D

<<

5.

O-ring

>>

C

<<

6.

Timing chain case assembly

>>

C

<<

7.

O-ring

>>

B

<<

8.

Timing chain tensioner cover

<<

C

>>

>>

A

<<

9.

Timing chain tensioner

>>

A

<<

10. Tensioner lever assembly

>>

A

<<

11. Timing chain guide

>>

A

<<

12. Timing chain

TIMING CHAIN

ENGINE MECHANICAL <4A9>

11A-50

REMOVAL SERVICE POINTS

<<A>> A/C COMPRESSOR AND CLUTCH

ASSEMBLY REMOVAL

1. Remove the A/C compressor and clutch assembly

together with the hose from the bracket.

2. Tie the removed A/C compressor and clutch

assembly with a string at a position where it will

not interfere with the removal and installation of

timing chain case assembly.

<<B>> ENGINE AND TRANSMISSION ASSEMBLY

HOLDING

Install a special tool for holding the engine and trans-

mission assembly.

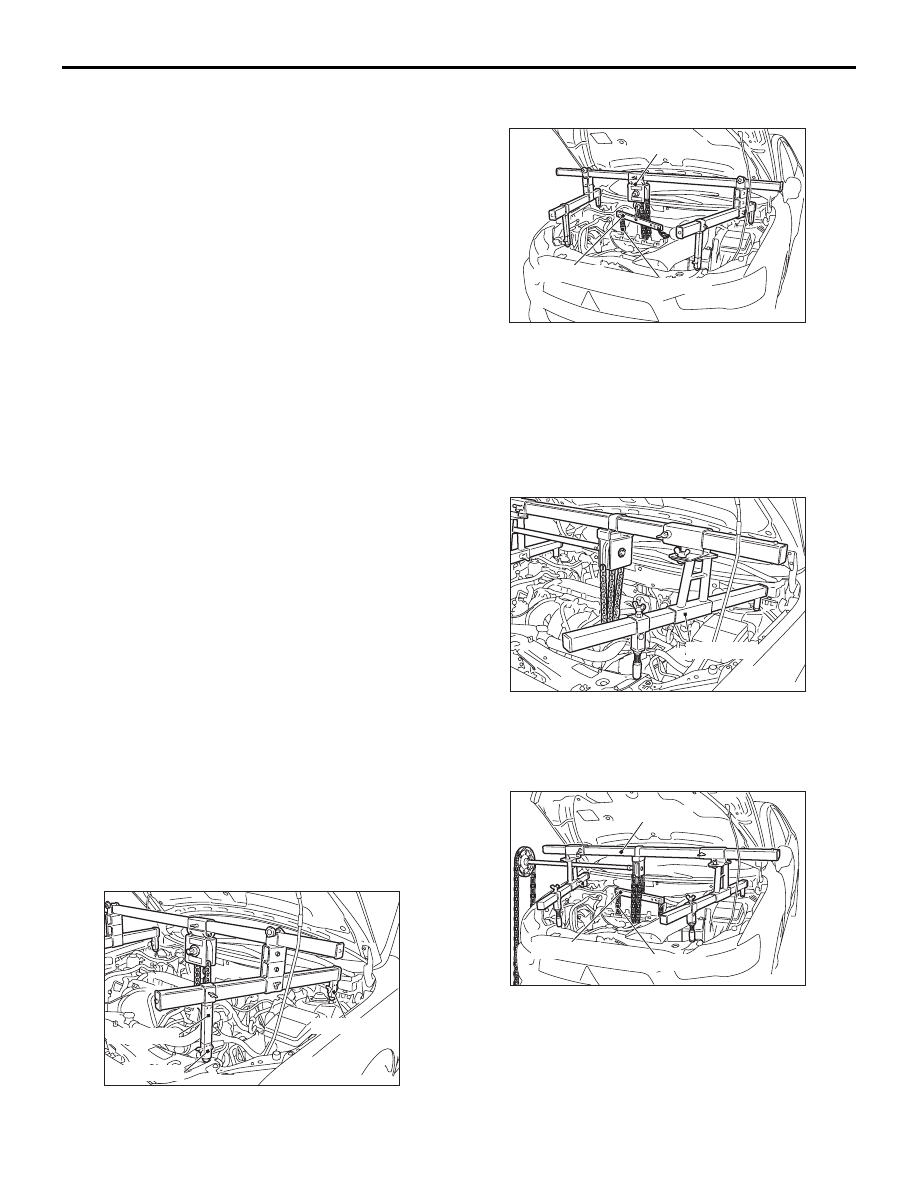

1. <When special tool engine hanger (MB991928) is

used>

(1) Assemble special tool engine hanger

(MB991928) (Set the following parts on the

base hanger).

• Slide bracket (HI)

• Foot x 4 (standard) (MB991932)

•

AC611565AC

MB991932

MB991932

MB991930

Joint x 2 (90) (MB991930)

(2) Set the foot of the special tool as shown in the

figure.

NOTE: Slide the slide bracket (HI) to adjust the

engine hanger balance.

AC700024AB

MB991454

MB991928

MB991527

(3) Install special tool engine hanger (MB991527)

and special tool engine hanger balancer

(MB991454) to the engine hanger, and set it to

special tool MB991928 to support the engine

and transmission assembly.

2. <When special tool engine hanger (MB991895) is

used>

AC611564AC

MB991895

(1) Set the foot of special tool engine hanger

(MB991895) as shown in the figure.

NOTE: Slide the foot to adjust the engine

hanger balance.

AC700023AB

MB991454

MB991895

MB991527

(2) Install special tool engine hanger (MB991527)

and special tool engine hanger balancer

(MB991454) to the engine hanger, and set it to

special tool MB991895 to support the engine

and transmission assembly.