Mitsubishi Lancer (4A9 engine). Manual - part 28

CAMSHAFT

ENGINE MECHANICAL <4A9>

11A-26

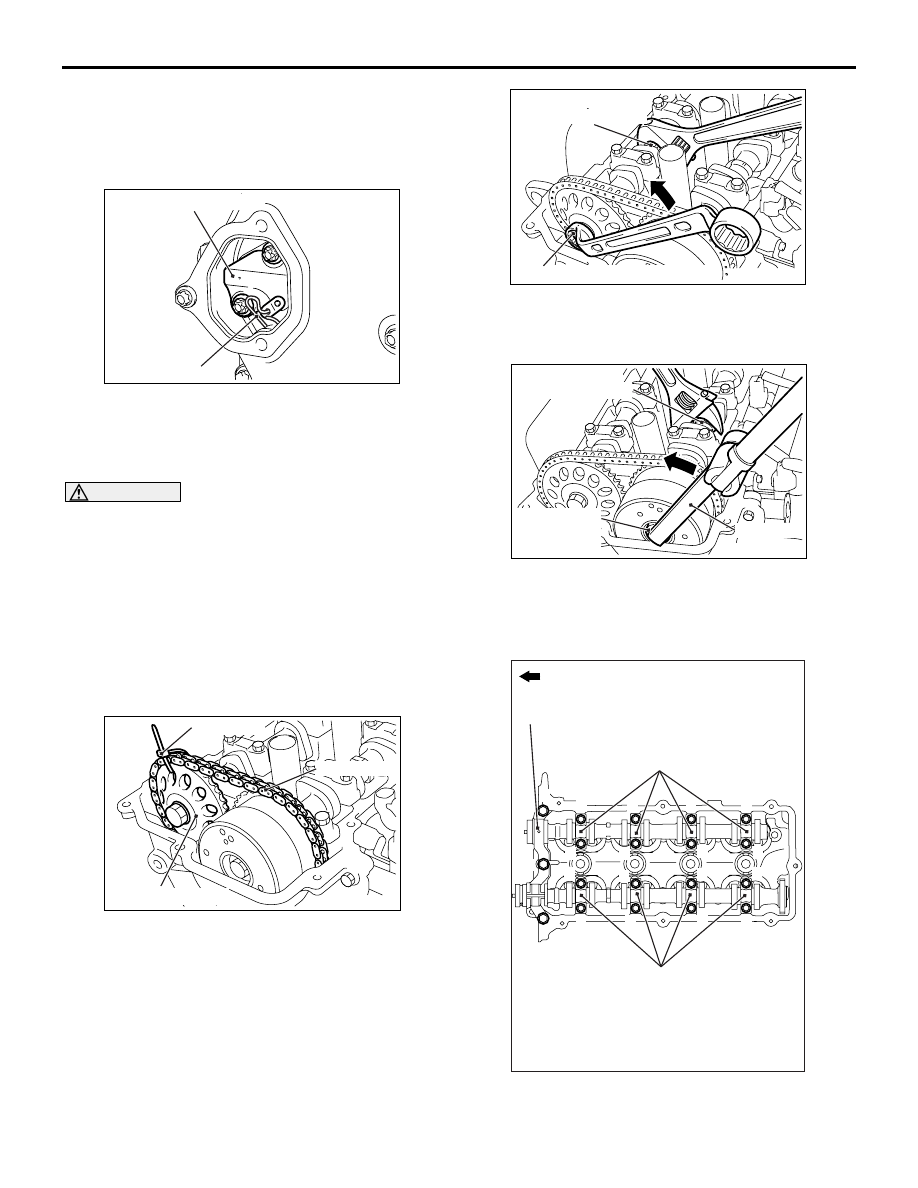

2. While holding the inlet camshaft hexagonal area

with a wrench or a similar tool, slightly turn the

exhaust camshaft clockwise to tighten the timing

chain at the timing chain tensioner side and

shorten the plunger of the timing chain tensioner.

AC311263

AB

Timing chain tensioner

Pin

3. With the plunger of the tensioner shortened, insert

a pin or a similar tool (3 mm or less in diameter) to

the hole shown in the illustration of the timing

chain tensioner.

CAUTION

Do not turn the crankshaft after removing the tim-

ing chain tensioner.

4. Loosen the timing chain tensioner mounting bolts,

and remove the timing chain tensioner from the

timing chain case hole.

<<C>> CAMSHAFT SPROCKET/ V.V.T.

SPROCKET ASSEMBLY/FRONT CAMSHAFT

BEARING CAP/CAMSHAFT BEARING CAP/

CAMSHAFT REMOVAL

AC312249

AB

Timing chain

Cable band

Camshaft sprocket

1. Fix the camshaft sprocket and the timing chain

using a cable band or a similar tool.

AC311264

AB

Hexagon part of

the exhaust camshaft

Camshaft sprocket mounting bolt

2. While holding the exhaust camshaft hexagonal

area with a wrench or a similar tool, loosen the

camshaft sprocket mounting bolt.

AC311265

AC

Hexagon part of

the inlet camshaft

V.V.T. sprocket

assembly

mounting bolt

MB991992

3. While holding the inlet camshaft hexagonal area

using a wrench or a similar tool, use special tool

torque wrench adapter (MB991992) to loosen the

V.V.T. sprocket assembly mounting bolt.

AC403719

AH

1

1

2

2

1

2

3

4

3

4

3

6

5

5

6

8

7

7

8

Engine front

Front camshaft

bearing cap

Camshaft bearing cap

Camshaft bearing cap