Mitsubishi Lancer (4A9 engine). Manual - part 26

AK402145

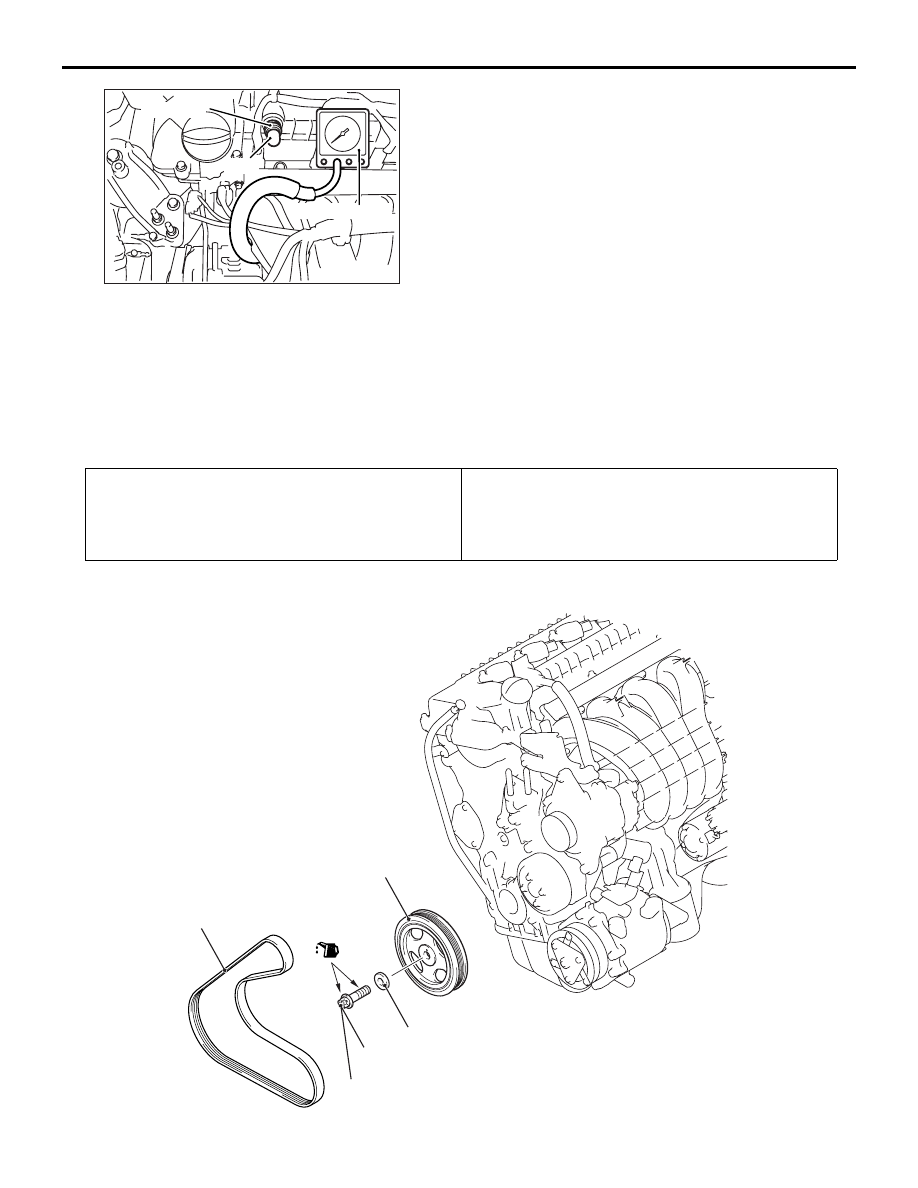

PCV valve

Plug

Vacuum gauge

AC

CRANKSHAFT PULLEY

ENGINE MECHANICAL <4A9>

11A-18

4. Disconnect the ventilation hose from the positive

crankcase ventilation (PVC) valve, and then

connect a vacuum gauge to the ventilation hose.

Plug the PCV valve.

5. Start the engine and check that idle speed is

approximately 750 r/min.

6. Check the intake manifold vacuum.

Limit: Minimum 60 kPa

7. Turn off the ignition switch.

8. Remove the vacuum gauge and then connect the

ventilation hose to the PCV valve.

9. Remove the M.U.T.-III.

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

M1112001604661

Pre-removal Operation

• Engine Room Under Cover Front B and Engine Room

Side Cover (RH) Removal (Refer to GROUP 51

− Under

Cover ).

Post-installation Operation

• Drive belt Tension Check and Adjustment (Refer to ).

• Engine Room Under Cover Front B and Engine Room

Side Cover (RH) Installation (Refer to GROUP 51

− Under

Cover ).

<Euro5>

AC613568 AD

1

3

4

2

50 N·m +60˚ 0 N·m

50 N·m +60˚

(Engine oil)