Mitsubishi Evolution X. Manual - part 967

FOG LIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-229

.

TECHNICAL DESCRIPTION (COMMENT)

If one of the fog lights does not Illuminate, the wiring harness

connector(s), the bulb may be defective.

.

TROUBLESHOOTING HINTS

• Burned-out fog light bulb

• Damaged harness wires and connectors

DIAGNOSIS

Required Special Tools:

• MB992006: Extra fine probe

• MB991223: Harness set

STEP 1. Check fog light (LH) connector A-43 or fog light

(RH) A-54 for loose, corroded or damaged terminals, or

terminals pushed back in the connector.

Q: Is fog light (LH) connector A-43 or fog light (RH) A-54 in

good condition?

YES : Go to Step 2.

NO : Repair or replace the damaged component(s). Refer

to GROUP 00E, Harness Connector Inspection

STEP 2. Check the fog light bulb.

(1) Remove the fog light bulb.

(2) Verify that the fog light bulb is not damaged or burned out.

Q: Is the fog light bulb in good condition?

YES : Go to Step 3.

NO : Replace the fog light bulb.

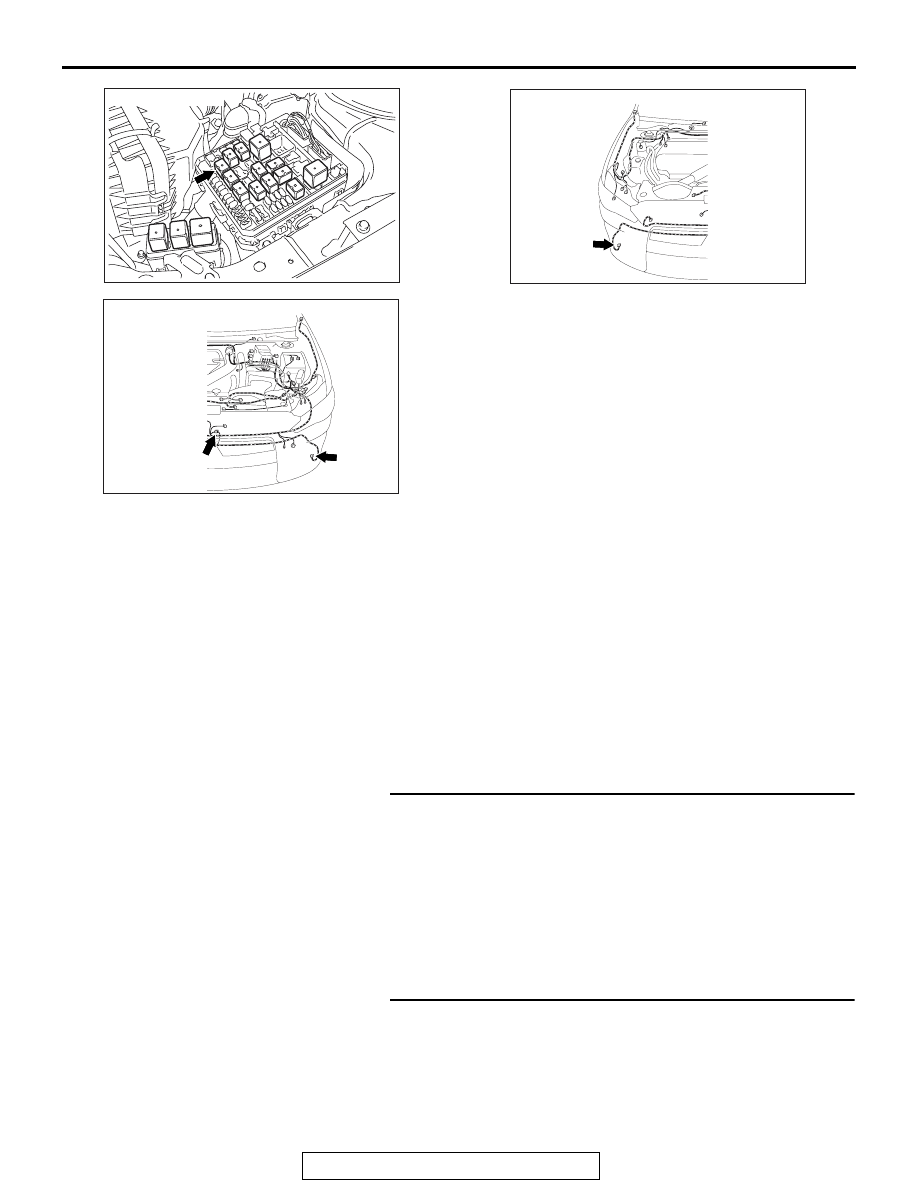

AC709111

Connector: A-15X

AH

AC708949AN

Connectors: A-43, A-50

A-43 (B)

A-50 (B)

AC708948AL

Connector: A-54

A-54 (B)