Mitsubishi Evolution X. Manual - part 950

HEADLIGHT

TSB Revision

CHASSIS ELECTRICAL

54A-161

.

TECHNICAL DESCRIPTION (COMMENT)

If any of the tail lights, the position lights or the

license plate lights does not Illuminate, the harness,

connector(s), or bulb(s) may have a problem, or the

fuse may be burned out.

.

TROUBLESHOOTING HINTS

• Malfunction of bulbs

• Malfunction of rear combination light

• Malfunction of rear combination light harness

• Malfunction of license plate light

• Malfunction of headlight

• Malfunction of tail light

• The wiring harness or connectors may have

loose, corroded, or damaged terminals, or termi-

nals pushed back in the connector

DIAGNOSIS

Required Special Tools:

• MB992006: Extra fine probe

• MB991223: Harness set

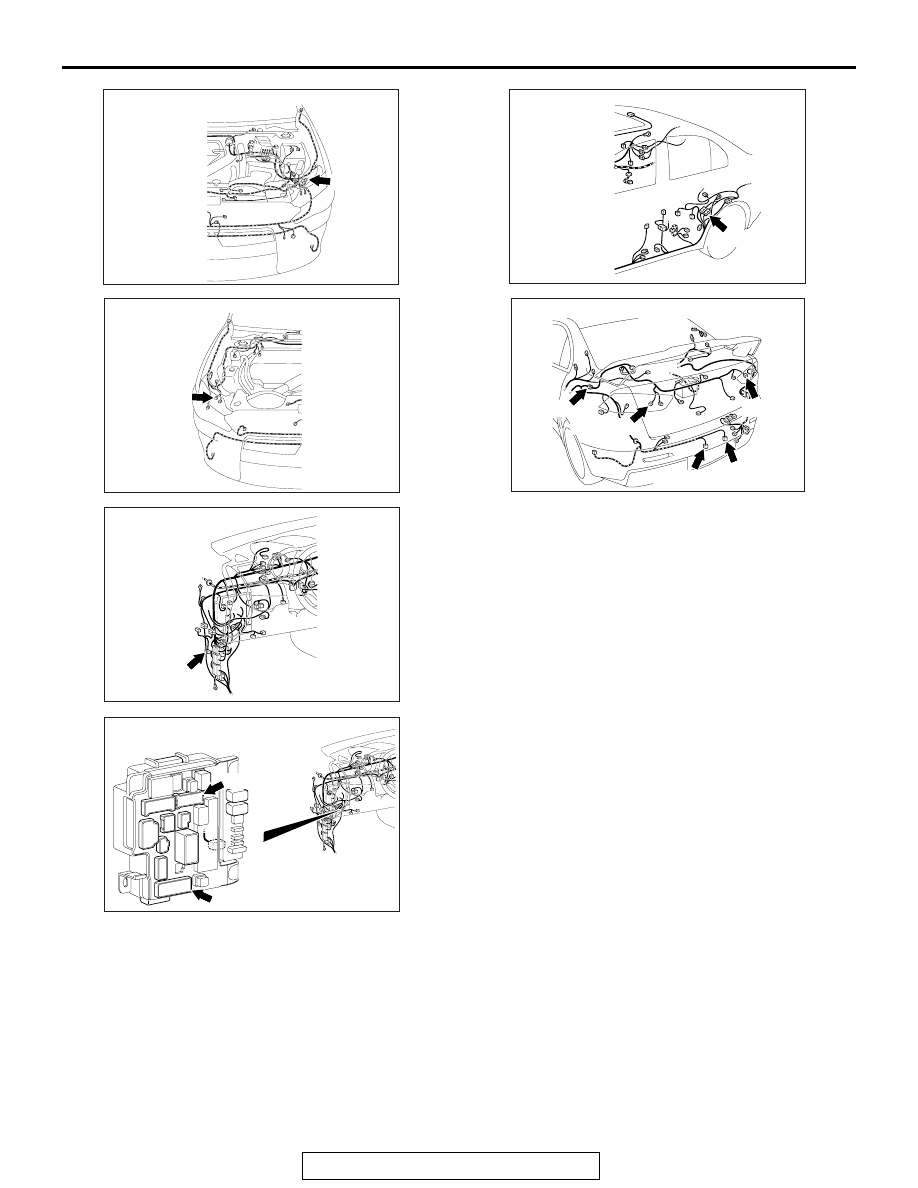

AC708949AH

Connector: A-40

A-40 (B)

AC708948AH

Connector: A-57

A-57 (B)

AC708950

Connector: C-43

BG

C-43 (B)

AC708972

Connectors: C-304, C-311

AW

C-311

C-304

AC708955AL

Connector: D-17

D-17 (BR)

AC708970AJ

Connectors: F-07, F-15, F-18, F-24, F-27

F-27

F-15 (GR)

F-18 (GR)

F-24 (GR)

F-07 (GR)