Mitsubishi Evolution X. Manual - part 470

KEY INTERLOCK AND SHIFT LOCK MECHANISMS

TSB Revision

TWIN CLUTCH- SPORTRONIC SHIFT TRANSMISSION (TC-SST)

22C-337

KEY INTERLOCK AND SHIFT LOCK MECHANISMS

REMOVAL AND INSTALLATION

M1225009800017

Pre-removal Operation

• Floor console bracket (A) and floor console side cover

removal (Refer to GROUP 52A

− Floor Console Assembly

.)

• Instrument panel cover lower removal <Leather combina-

tion interior package (Vehicles without side air bag)>

(Refer to GROUP 52A

− Instrument Lower Panel

.)

• Steering column lower cover removal (Refer to GROUP

37

− Steering Shaft

• Foot duct (driver's side) removal (Refer to GROUP 55 −

Post-installation Operation

• Foot duct (driver's side) installation (Refer to GROUP 55 −

• Steering column lower cover installation (Refer to GROUP

37

− Steering Shaft

• Instrument panel cover lower installation <Leather combi-

nation interior package (Vehicles without side air bag)>

(Refer to GROUP 52A

− Instrument Lower Panel

.)

• Floor console bracket (A) and floor console side cover

installation (Refer to GROUP 52A

− Floor Console

Assembly

.)

• Key interlock mechanism check (Refer to

• Shift lock mechanism check (Refer to

.)

• Shift lever operation check (Refer to

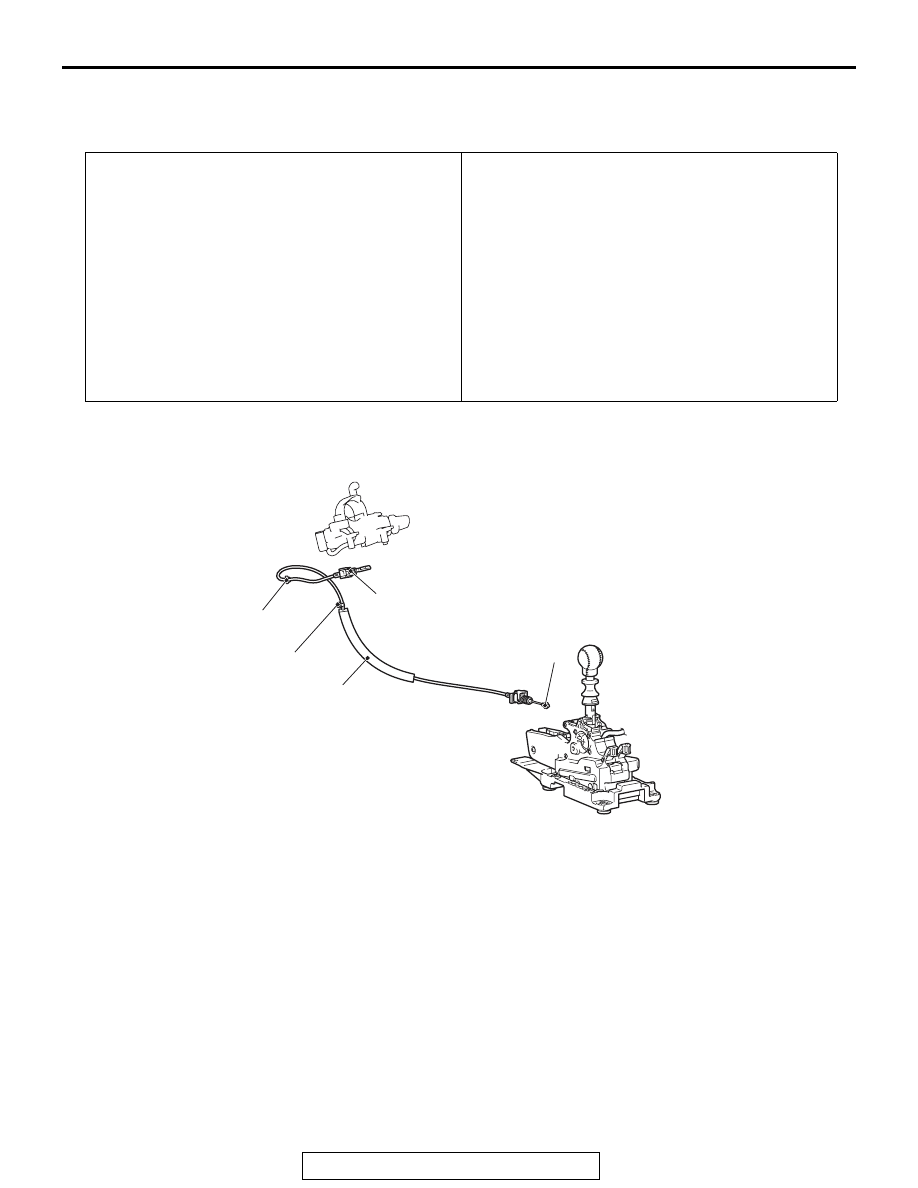

AC705527

AC709660AB

2

1

5

3

4

Removal steps

1.

Band clip

2.

Wiring harness clip

>>

B

3.

Key interlock cable

connection (shift lever side)

<<

A

>>

>>

A

4.

Key interlock cable

connection (steering side)

5.

Key interlock cable

Removal steps