Mitsubishi Evolution X. Manual - part 194

EXHAUST MANIFOLD

TSB Revision

ENGINE OVERHAUL

11B-23

>>G<< EXHAUST FITTING BRACKET

INSTALLATION

AK703142AC

Cylinder block

Exhaust fitting

Exhaust fitting

bracket

1. After temporarily tightening the exhaust fitting bracket with

the installation bolts, check the exhaust manifold fastens

securely to the cylinder block and the exhaust fitting.

2. Tighten the cylinder block side bolt to the specified

tightening torque.

Specified torque: 51

± 7 N⋅ m (38 ± 4 ft-lb)

3. Tighten the exhaust fitting bracket side bolt to the specified

tightening torque.

Specified torque: 64

± 5 N⋅ m (47 ± 3 ft-lb)

.

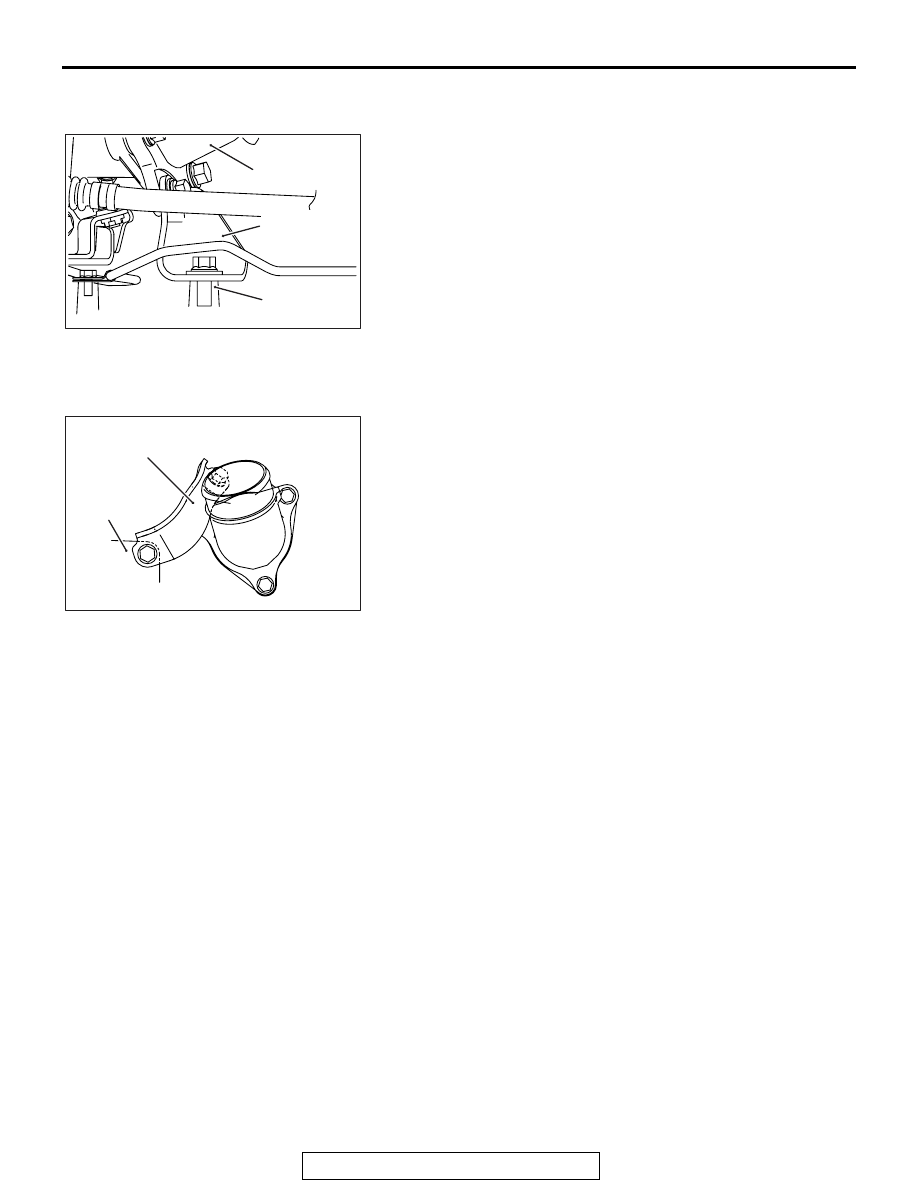

>>H<< TURBOCHARGER COMPRESSOR

BRACKET INSTALLATION

AK703144AC

Turbocharger

compressor bracket

Cylinder block

1. After temporarily tightening the turbocharger compressor

bracket with the installation bolts, check the exhaust

manifold fastens securely to the cylinder block and the

turbocharger.

2. Tighten the cylinder block side bolt to the specified

tightening torque.

Specified torque: 51

± 7 N⋅ m (38 ± 4 ft-lb)

3. Tighten the turbocharger side bolt to the specified tightening

torque.

Specified torque: 51

± 7 N⋅ m (38 ± 4 ft-lb)