Content .. 1289 1290 1291 1292 ..

Mitsubishi Evolution X. Manual - part 1291

ON-VEHICLE SERVICE

TSB Revision

HEATER, AIR CONDITIONING AND VENTILATION

55-115

PERFORMANCE TEST

M1552001400957

The vehicles to be tested should be parked out of direct sun-

light.

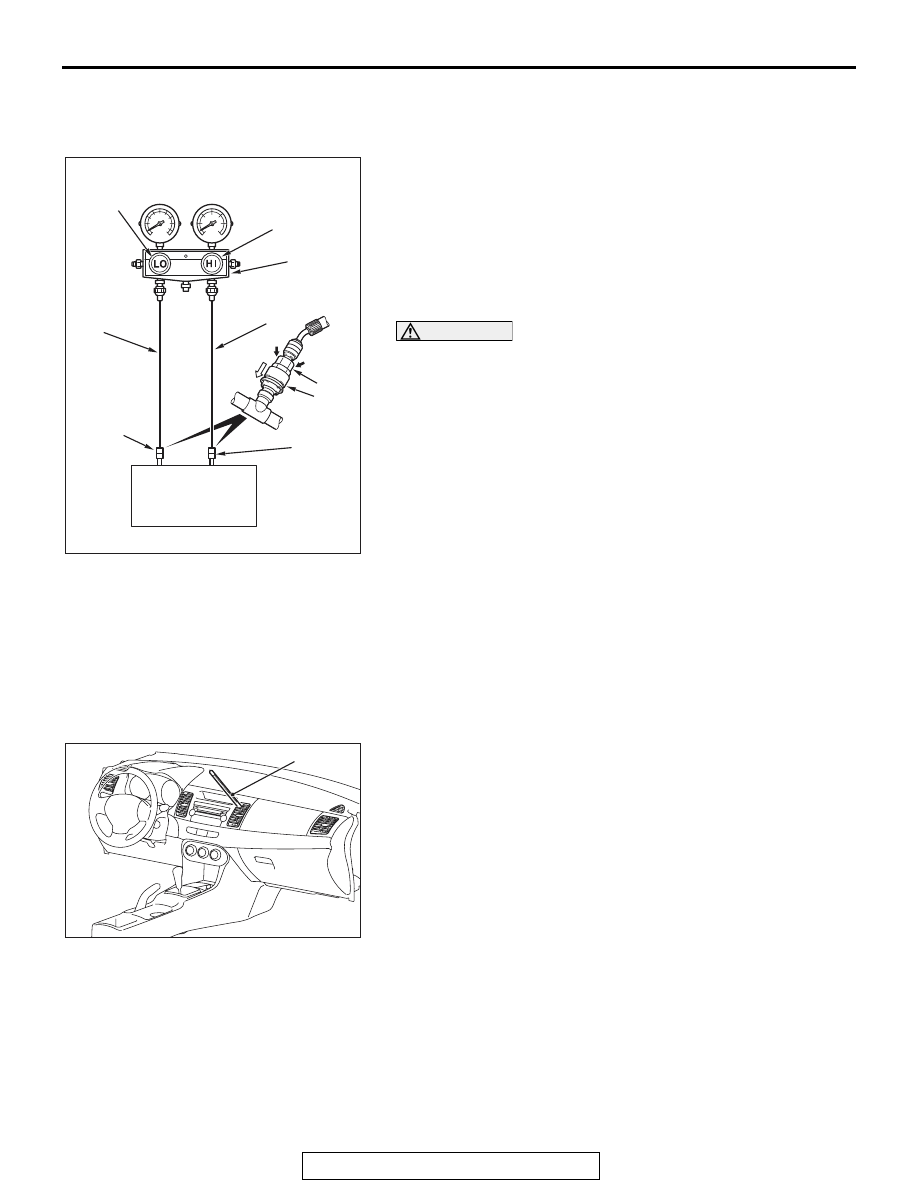

1. Close the high and low-pressure valve of the gauge

manifold.

2. Connect the charging hose (blue) to the low-pressure valve

and connect the charging hose (red) to the high-pressure

valve of the gauge manifold.

3. Install the quick joint (for low-pressure) to the charging hose

(blue), and connect the quick joint (for high-pressure) to the

charging hose (red).

CAUTION

• To connect the quick joint, press section A firmly

against the service valve until a click is heard.

• When connecting, run your hand along the hose while

pressing to ensure that there are no bends in the hose.

4. Connect the quick joint (for low-pressure) to the

low-pressure service valve and connect the quick joint (for

high-pressure) to the high-pressure service valve.

NOTE: The high-pressure service valve is on the A/C pipe

and the low-pressure service valve is on the suction hose.

5. Start the engine.

6. Set the A/C controls as follows:

• A/C switch: A/C − ON position

• Mode selection: FACE position

• Temperature control: MAXIMUM COOLING position

• Air selection: RECIRCULATION position

• Blower switch: Maximum air volume

7. Set the engine speed to the idle speed.

8. Engine should be warmed up with hood, doors and windows

opened.

9. Insert a thermometer in the center air outlet and operate the

engine for 20 minutes.

NOTE: If the A/C clutch cycles, take the reading before the

clutch disengages.

10.Note the discharge air temperature.

AC609415

Low-pressure

valve

High-pressure

valve

Gauge manifold

Charging

hose (Red)

A

Sleeve

Charging

hose (Blue)

Adaptor

valve

(For

low-pres-

sure)

Adaptor

valve

(For high-

pressure)

Low-

pressure

service

valve

High-

pressure

service

valve

AC

AC609414AB

Thermometer