Mitsubishi Evolution X. Manual - part 8

BODY REPAIR

TSB Revision

BASE OF BODY REPAIR

9-29

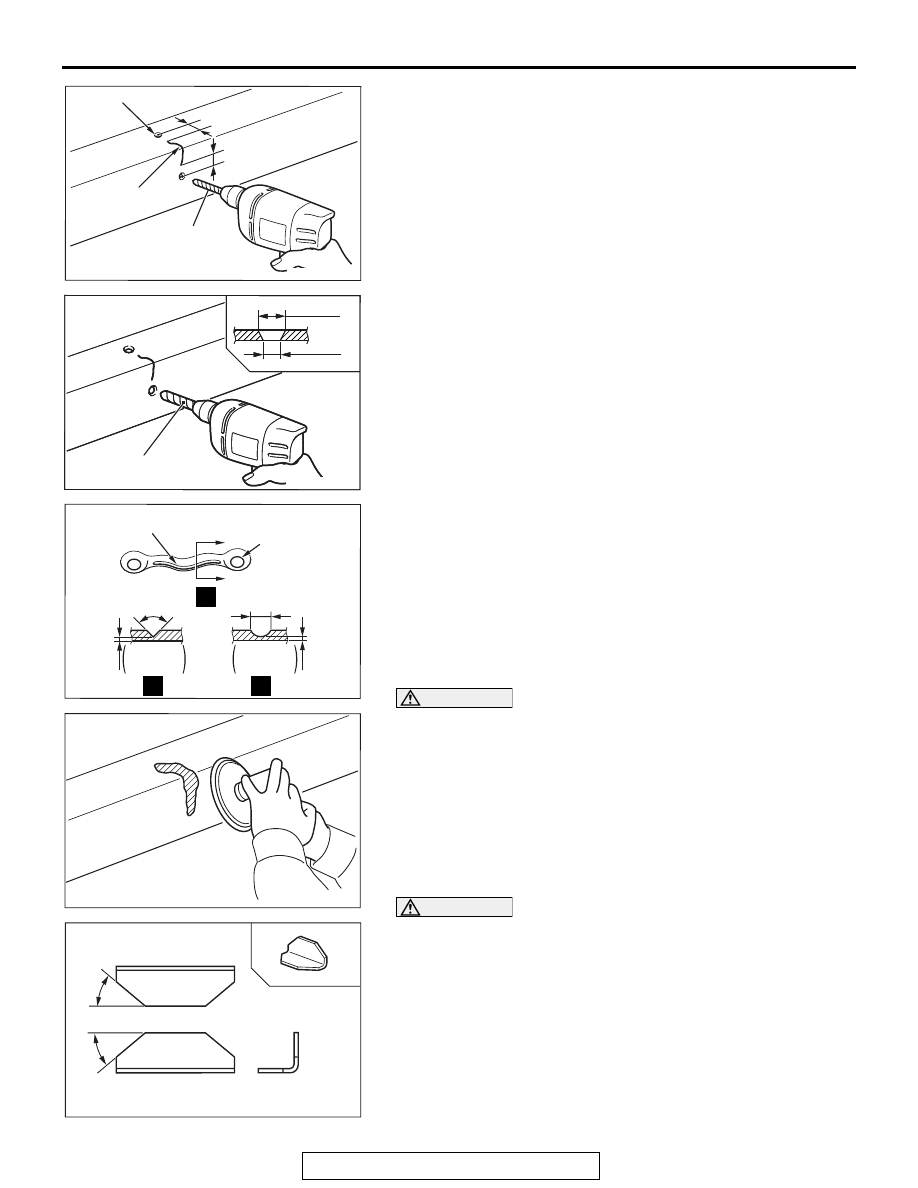

1. Remove the components near the crack.

2. Make

φ 6 − 8 mm (0.24 − 0.31 inch) holes (to prevent further

cracking), by using a drill, at points 7

− 8 mm (0.28 − 0.31

inch) from the crack ends.

3. Use a

φ 10 − 12 mm (0.39 − 0.47 inch) drill to bevel the hole

openings.

4. Use a chisel or gouging tool to open up the crack and holes,

and then fill the crack and holes by MIG welding.

CAUTION

• Gas welding should be avoided because it causes ther-

mal distortion of the frame.

• When using a grinder for finishing, be careful not to

grind the frame excessively.

5. Using a grinder for finishing after welding.

CAUTION

• The reinforcement plate should completely cover the

cracked part.

• The reinforcement plate should be the same thickness

and material as the frame.

6. To avoid a concentration of stress, prepare a reinforcement

plate that has been cut to 30

− 45 degree angle at both

ends.

AB301469

Crack-stop hole

Crack

A

A

Ø6 – 8 mm

(0.24 – 0.31 in)

A : 7 – 8 mm (0.28 – 0.31 in)

AD

AB301470AB

Ø10 – 12 mm

(0.39 – 0.47 in)

Ø10

–

12 mm

Ø6

–

8 mm

AB301470 AC

(0.24

–

0.31 in)

(0.39

–

0.47 in)

AB301471AD

Crack

Crack-stop

hole

Approx.

8 mm

(0.31 in)

Approx.

1 mm

(0.04 in)

Approx.

1 mm

(0.04 in)

Approx.

90˚

If a chisel

is used

If a gouge

is used

A

A

A

AB200131AB

AB301461

A

A

A : 30 – 45˚

AB