Mitsubishi Lancer Evolution X. Manual - part 338

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-417

DTC SET CONDITIONS

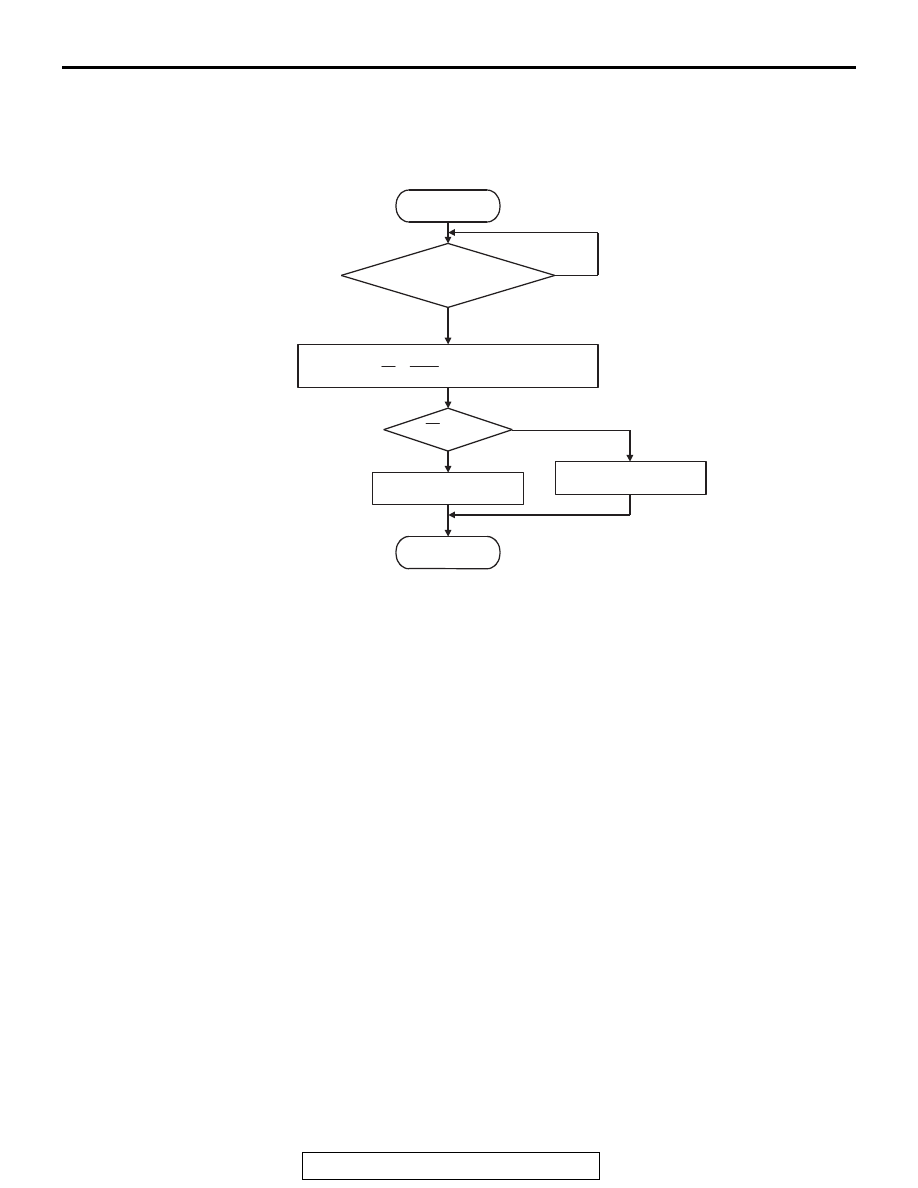

Logic Flow Chart

.

Check Conditions

• Engine speed is 3,500 r/min or lower.

• Accelerator pedal is depressed.

• Mass airflow is between 13 and 45 g/sec.

• More than 3.5 seconds have elapsed after the

above-mentioned three conditions have been

met.

• Intake air temperature is higher than −10° C

(14° F).

• Barometric pressure is higher than 76 kPa (22.4

in.Hg).

• Under the closed loop air/fuel ratio control.

• Vehicle speed is 1.5 km/h (1.0 mph) or more.

• The ECM monitors the maximum 5 times per

drive cycle under these conditions.

• Short-term fuel trim is higher than −

20 percent

and lower than +17 percent.

• The cumulative mass airflow is higher than 1,638

g.

Judgement Criterion

• When the monitoring for 10 seconds is carried

out 5 times, the frequency ratio of rear and front

signals is the specified value or more.

NOTE: The specified value varies depending on the

average air flow rate.

.

FAIL-SAFE AND BACKUP FUNCTION

• None

.

OBD-II DRIVE CYCLE PATTERN

Refer to Diagnostic Function − OBD-II Drive Cycle −

Pattern 3

.

.

TROUBLESHOOTING HINTS (The most

likely causes for this code to be set are:)

• Catalytic converter deteriorated.

• Heated oxygen sensor failed.

• Exhaust leak.

• ECM failed.

Start

Monitoring

conditions

Malfunction

Good

End

No

No

Yes

Yes

Rf > R0

Calculate average frequency

ratio (Rf = Fr/Ff) of specified times

R0: Average threshold value

AK604337