Mitsubishi Lancer Evolution X. Manual - part 332

MULTIPORT FUEL INJECTION (MFI) DIAGNOSIS

TSB Revision

MULTIPORT FUEL INJECTION (MFI)

13A-393

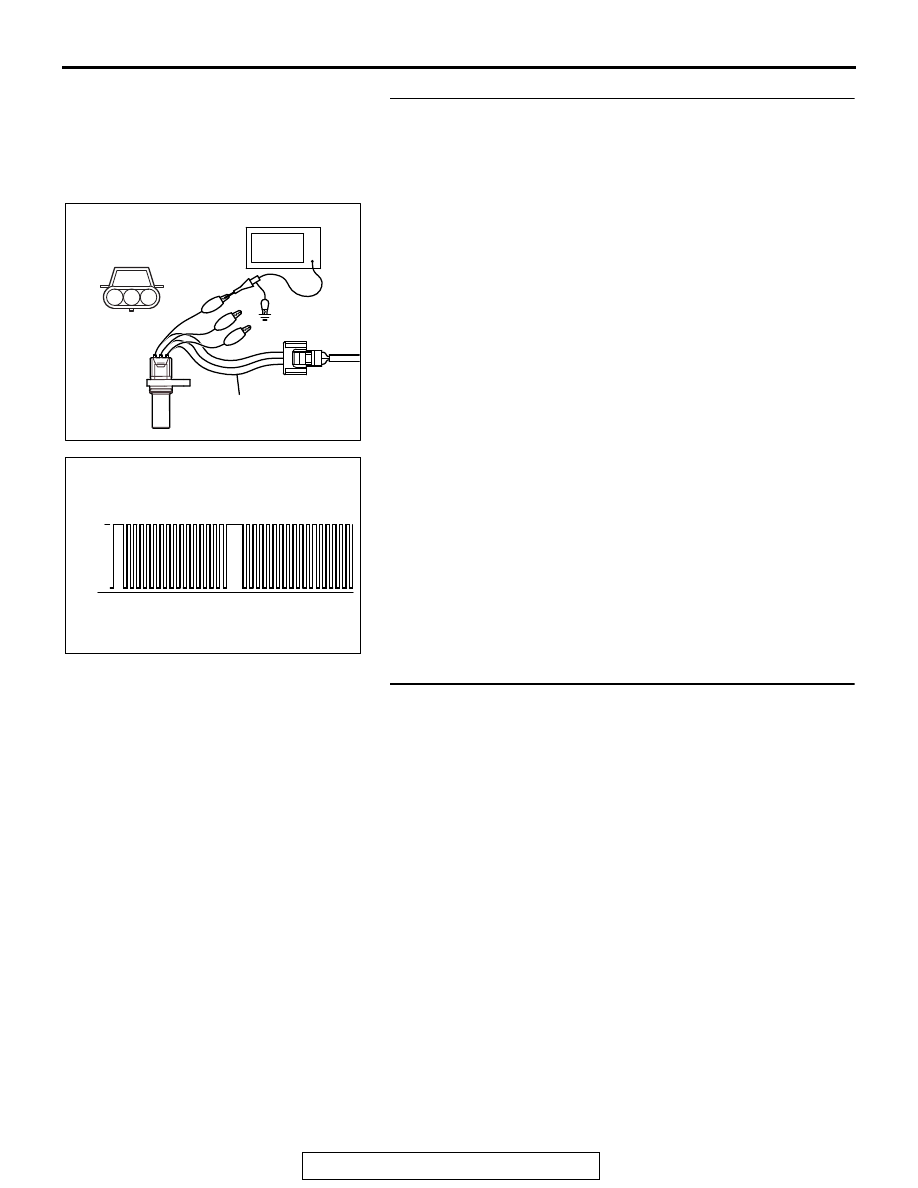

STEP 2. Using the oscilloscope, check the crankshaft

position sensor.

(1) Disconnect the crankshaft position sensor connector B-13

and connect the test harness special tool (MB991709)

between the separated connectors.

(2) Connect the oscilloscope probe to terminal No. 3 of the

crankshaft position sensor connector.

NOTE: When measuring with the ECM side connector, dis-

connect all ECM connectors. Connect the check harness

special tool (MB992110) between the separated connec-

tors. Then connect the oscilloscope probe to the check har-

ness connector terminal No. 8.

(3) Start the engine and run at idle.

(4) Check the waveform.

• The waveform should show a pattern similar to the illus-

tration.

(5) Turn the ignition switch to the "LOCK" (OFF) position.

Q: Is the waveform normal?

YES : Go to Step 3.

NO : Go to Step 5.

STEP 3. Check harness connector B-13 at the crankshaft

position sensor and harness connector B-09 at ECM for

damage.

Q: Is the harness connector in good condition?

YES : Go to Step 4.

NO : Repair or replace it. Refer to GROUP 00E, Harness

Connector Inspection

. Then go to Step 20.

AK704086

3

2

1

AB

Crankshaft position

sensor connector

Oscilloscope

MB991709

AK604547

5Volt

Normal waveform

AB