Mitsubishi Lancer Evolution X. Manual - part 74

OIL PAN

TSB Revision

ENGINE MECHANICAL

11A-49

REMOVAL SERVICE POINTS

.

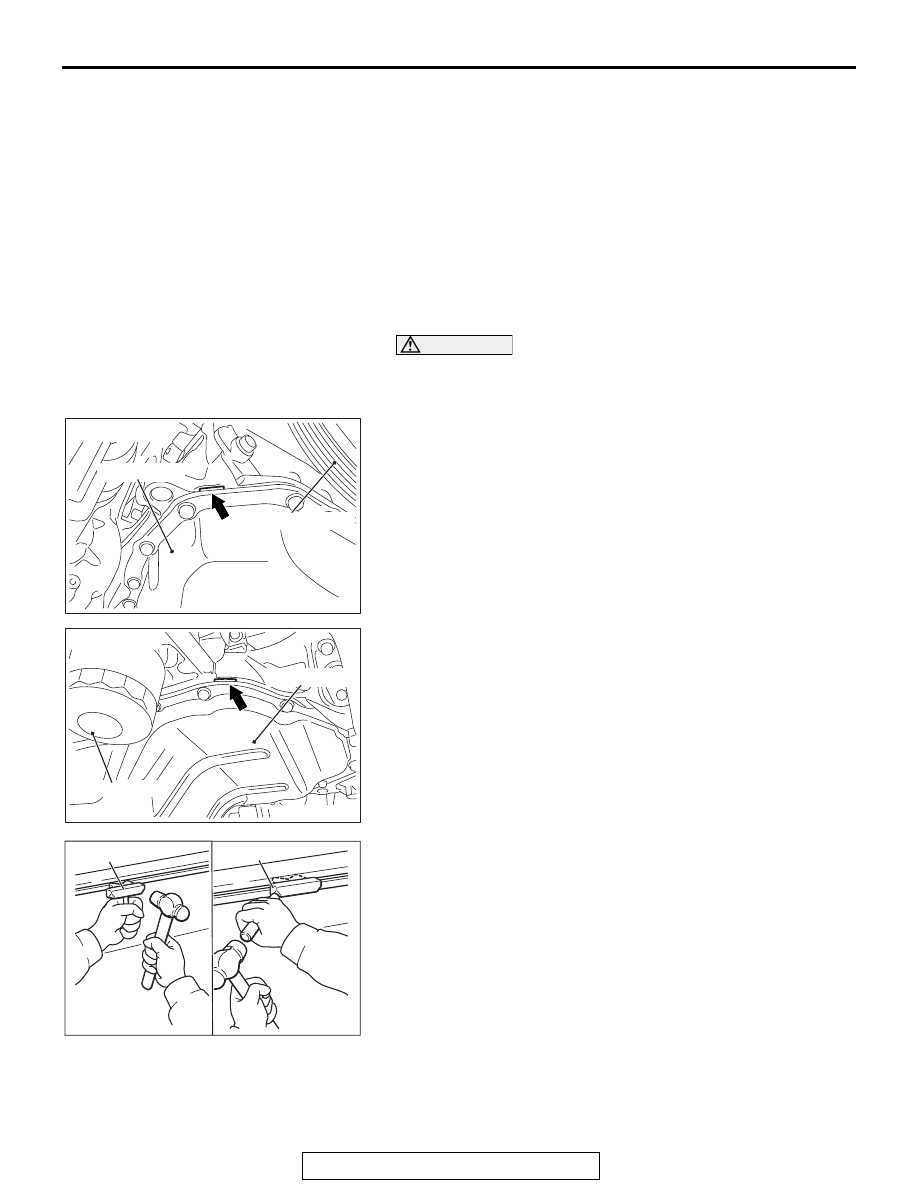

<<A>> A/C COMPRESSOR AND CLUTCH ASSEM-

BLY REMOVAL

1. Remove the A/C compressor and clutch assembly together

with the hose from the bracket.

2. Tie the removed A/C compressor and clutch assembly with

a string at a position where they will not interfere with the

removal and installation of engine oil pan.

.

<<B>> ENGINE OIL PAN REMOVAL

1. Remove the engine oil pan mounting bolts.

CAUTION

Do not forcibly drive in special tool MD998727 to avoid

damage to the engine oil pan seal surface of cylinder block

assembly.

2. Insert special tool MD998727 from the engine oil pan

removal groove of the cylinder block assembly.

3. Lightly tap the special tool with a hammer to slide the oil pan

seal surface, cut off the liquid gasket, and remove the

engine oil pan.

AC705459AC

<Engine front>

Engine oil pan

Crankshaft pulley

AC705460 AC

Engine oil pan

<Engine rear>

Engine oil filter

AC102324 AB

MD998727

MD998727